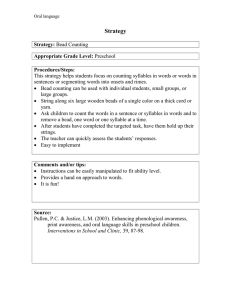

RohrmanThesis 2

advertisement

Micro Programmable Object Navigation

Gadget (µ-PONG)

for Studying Electroosmotic

Flow in a PDMS Microchannel

Brittany Rohrman

Background and Significance:

One of the most useful features of microfluidic devices, in the context of biological

research, is their ability to serve as tiny fluidic enclosures for either individual or small

collections of cells. The small volume of such enclosures can enable the in vitro study of cellcell interactions as well as paracrine and autocrine signaling events that would be difficult to

achieve in traditional large Petri dish cell culture environments, which typically have extremely

large (and non-physiological) ratios of cell media fluid volume to cell volume. Microfluidic

devices are more comparable to in vivo tissue environments because they are fabricated to

house cells in small fluidic volumes. However, one constraint on the long-term observation of

cells enclosed in tiny fluidic enclosures is the need to replenish the nutrient solutions

surrounding the cells. Another constraint when utilizing microfluidic devices is the need for very

low flow rates capable of manipulating cells without disrupting pre-established biochemical

diffusion gradients. These low-flow techniques typically require expensive (~$3000) precision

syringe pumps to provide on-demand, extremely low fluid flow rates. An attractive alternative to

this expensive mechanical syringe pump technology is an electro-kinetic technique that can

induce low volume electroosmotic flow in microchannels.

Objective:

The goal of my senior honors thesis project is to create an automated testing system (µPONG) for characterizing electroosmotic flow (EOF) in poly(dimethylsiloxane) (PDMS) devices.

My hope is that this system will be used to characterize EOF in particular PDMS devices

intended for biological research in order to demonstrate the possibility of utilizing EOF as a

pumping system in such devices. The basic premise of my research is that by using the

computer-controlled µ-PONG system to control the movement of a polystyrene bead in a PDMS

microchannel, the recorded motion of the bead will serve as a measure of the electroosmotic

flow strength over time. Hence, this characterization may be an important factor in the design of

biological experiments. Once the system is optimized for well-controlled fluid delivery, the µPONG system may also serve as a tool for manipulating particles or cells in PDMS microfluidic

devices.

Introduction:

Poly(dimethylsiloxane), or PDMS, is a polymer often used to construct microscopic or

nano-scale channels. Because PDMS is permeable to gases, nontoxic to cells, and optically

clear,1 these channels often serve as an optimal environment in which electroosmotic flow

(EOF) is used to manipulate cells2 and biomolecules3 for study. In experiments utilizing EOF, a

potential difference is applied across an oxidized PDMS channel filled with a buffer. Cations

from the buffer are attracted to anions bound to the walls of the channel, forming what is known

as the electric double layer (EDL), which is only a few nanometers wide (Figure 1).

2

Oxidized PDMS

EDL

Electroosmotic Flow

Figure 1: Electroosmotic flow (EOF). When an electric field

is applied across the channel, positive ions from electric

double layer (EDL) move toward the negative electrode,

dragging the rest of the solution in that direction.

The potential difference causes the layer of cations to move toward the negative electrode,

pulling the rest of the solution in the same direction via viscous drag.4 This phenomenon is

known as electroosmotic flow. The flow is often quantified by the electroosmotic mobility,

eo

,

which is defined by (the permittivity of the solution), (the zeta potential), and (the

viscosity of the solution).5 Another common measure of electroosmotic flow is the

electroosmotic velocity, veo, which is closely related to the electroosmotic mobility. The

electroosmotic velocity is defined as

veo E eo ,

where E denotes the applied electric field.6

Electroosmotic flow has been implemented in a wide variety of applications, often

serving as a pump in lab-on-a-chip (LOC) microfluidic devices.7 LOC devices allow bioassays

to be performed on a much smaller scale, reducing the time and volume of reagents required for

traditional methods. Electroosmotic flow is ideal for use in LOC devices because it requires no

moving parts and may be controlled very precisely, unlike pressure-driven flow. Another

potential advantage of EOF is that the velocity of the fluid is the same throughout the cross

section of the channel (plug flow), while the velocity profile of pressure-driven fluid flow is

parabolic (Poiseuille flow). However, the strength of the EOF in oxidized PDMS channels has

been reported to attenuate over a period of just a few hours.8 This research aims to quantify

this effect by studying the movement of fluorescent polystyrene beads manipulated by EOF in a

PDMS microchannel. Once these time-dependent characteristics of electroosmotic flow are

known, use of the flow may be optimized for various microfluidic applications.

3

Methods:

Microfabrication of PDMS devices

PDMS microchannels were made using standard microfabrication and soft lithography

methods (Figure 2). First, SU-8 photoresist on a silicon support is exposed to ultraviolet light

through a mask. The light cures the exposed photoresist, leaving the photoresist obscured by

the mask uncured. The uncured photoresist is then dissolved, leaving a raised pattern defined

by the mask called a master. After further surface treatments, uncured (liquid) PDMS is poured

onto the master and degassed to remove bubbles. The PDMS is then baked overnight to

solidify the polymer. After exposure to an oxygen plasma for 30 seconds to create negative

charges (Si-0–) on the PDMS surface (for our devices, a PDC-32G Plasma Cleaner/Sterilizer

was used on the “high” power setting), the PDMS is irreversibly bonded to a clean glass slide.

Our devices were filled with 10 mM monobasic potassium phosphate buffer at pH 7.0

immediately after plasma bonding. Carboxylated or uncarboxylated fluorescent polystyrene

beads (Polysciences, Inc. Fluoresbrite YG microspheres, CV = 5%) with diameters of 3 or 10

microns were used. Several microliters of beads at concentrations between 0.01 and 0.001%

solid were deposited into one end of the channel using a micropipette. In some experiments,

the pressure was equalized by pumping additional buffer into the channel. Then a computer

program was used to control and/or record the movement of the bead.

UV light

mask

1

photoresist

and silicon wafer

2

master

3

PDMS poured

into master

4

PDMS bonded

to glass

Figure 2: Soft lithography and microfabrication of PDMS channels.

The µ-PONG system

The µ-PONG system consists of a DAQ board, an external voltage switching circuit, and

a camera, which are controlled by a computer program written in a LabView programming

environment (Figure 3). The computer is connected to a National Instruments USB-6009 device

capable of producing an analog voltage ranging from zero to five volts or a digital control signal

(on = 0 volts, off = 5 volts) (Figure 4). To increase the range of possible voltages used for

experiments, an external circuit was designed and built to amplify the USB analog voltage by a

factor of 1.83 (Figure 5). A digital voltage channel from the USB device is also connected to the

4

circuit in order to control the directional sense (or sign) of the voltage at the output leads, such

that changing the state of the digital signal reverses the direction of the potential difference

across the leads. The analog output signals from this external circuit establish a voltage

between the electrodes that are inserted at each end of the microfluidic channel (Figure 6).

Thus, a voltage is set up across the channel that causes electroosmotic flow.

Gold electrode

Goal posts

PDMS

Glass

Polystyrene bead

-fluidic

device

Control box

Objective

-scope

stage

Dichroic

mirror

Excitation

Ex filter

Em filter

Camera /

detector

Computer

Figure 3: Schematic diagram of the µ-PONG system. Two electrodes from

the control box are inserted at each end of the PDMS microchannel, which

is imaged through a camera via fluorescence microscopy. A LabView

program displays the image from the camera and communicates with a

USB device and external circuit housed inside a control box. When the

bead reaches a virtual goalpost, the program detects the bead and reverses

the direction of the voltage across the channel, keeping the bead moving

between the goalposts.

The LabView program continually retrieves and displays an image of the microchannel in

real time. Based on the image, the user utilizes the software to specify two virtual “goalpost”

regions of interest located at opposite ends of the imaged channel, typically about 200 microns

apart. The pixel intensities of the goalposts are compared to a user-specified target intensity

value in order to determine if a bright bead has entered a goalpost region. When that target

intensity value is reached or exceeded, the program sends a signal via the USB port to the DAQ

device, changing the state of the digital voltage channel connected to the external circuit. That

signal reverses the polarity of the voltage across the PDMS microchannel, thereby reversing the

direction of the EOF (see Appendix A for block diagram of LabView program). This strategy

works well because fluorescence microscopy is used to capture the image of the channel,

causing the bead to appear brighter than anything else in the channel. Thus, whenever the

bead reaches a region of interest, the reversal of the EOF causes it to move toward the other

region of interest, where the process is repeated. The bead moves back and forth between the

regions of interest much like a ball moves back and forth during a game of ping pong, allowing

experiments to run for long periods of time.

5

Figure 4: The NI-USB

6009

device

relays

signals

from

the

computer to the circuit.

Figure 5: The external

circuit

amplifies

the

signal from the USB

device and changes the

direction of the voltage.

Figure 6: The electrodes

at each end of the PDMS

channel

cause

EOF,

which moves the bead.

The LabView user interface

Before the program is run, the user can specify channel width, device age, and

other comments in a table on the front panel labeled “parameters” (Figure 7). On the

front panel, the user may also specify the physical digital and analog output channels of

the USB device as well as their minimum and maximum voltages, although these are

already set to default values. The user clicks the “run” arrow to execute the program.

Instructions for saving the parameters and subsequent data are displayed before the

user is asked to specify a *.lvm filename and location to save the parameter table. On

the front panel, the user specifies the desired analog output voltage to send to the USB

device via a slider. The user must also specify the pixel locations of the regions of

interest. The “left indicator” and “right indicator” are illuminated each time the bead is

detected in the specified region of interest during the experiment.

Figure 7: LabView interface. The user may specify the location of

the virtual goalposts, the detection threshold, and the voltage

6

across the channel. The user may also pause the EOF, save data,

record a video, and specify the mode of the system (“manual” or

“automatic”).

The user may run the program in a manual or automatic mode by clicking the

“Manual/Auto” button on the front panel. The “manual” mode allows the user to switch

the polarity, and thus the direction of the EOF, by clicking the “Left/Right” button on the

front panel. The “auto” mode detects the bead at the regions of interest and reverses

the polarity automatically. The user may also turn on or off the voltage across the

channel by clicking the “Pause/Run” button on the front channel. The “pause” mode

simply sets the voltage to zero, while the “run” mode establishes the voltage set on the

slider.

To record the analog output voltage, the voltage polarity, and whether the

desired analog output voltage is “running” or “paused,” the user must click the “Record”

button on the front panel. When the record button is on, these parameters as well as the

timestamp are recorded each time the voltage polarity changes. When prompted, the

user should select the file where the parameters were saved previously in order to

append the data to the same file. The user may also save a *.avi movie by clicking the

“Record” button located below the image display. When the user clicks the “stop” button

on the front panel, the program ceases to execute.

Voltage-switching circuit

One of the design goals of the µ-Pong system was to incorporate an easy way to

vary the magnitude of the applied voltage delivered to the microfluidic device. For this

purpose, we utilized a computer-controlled 12-bit digital-to-analog converter, which is a

component of the National Instruments USB-6009 device. However, the output of this

particular device is limited to a unipolar 0-5V range, lacking the ability to reverse the

applied voltage in order to reverse the motion of the flow. Because reversing the

direction of the EOF is the main function of the µ-PONG system, a circuit utilizing

integrated circuit analog switches (74HC4066N) was designed to provide a variable

magnitude and reversible voltage system.

The circuit is powered by a power supply that converts 120V AC voltage to 15V

and -15V (DC voltage). A positive regulator converts the 15V voltage to 5V and a

negative regulator converts the -15V voltage to -5V in order to power five LEDs that

serve as indicators and the integrated circuits (a hex inverter, operational amplifiers, and

a digital switch - see Appendix B for the analog switch datasheet). One LED is

connected to ground such that when it is powered, a voltage is established across it,

indicating that the power is on (see Figure 8). Digital signals two and three are also

connected to current-limited LEDs to indicate whether the system is in manual or

automatic mode and whether the system is paused or running.

The voltage-switching function of the µ-PONG circuitry works by connecting

output amplifiers to either a signal which is equal to the analog input voltage or a signal

which is equal to minus the analog input voltage, depending on whether leftward motion

or rightward motion is required by the control logic signals. Digital signal one serves as

the switch for changing the polarity of the voltage across the microfluidic channel. When

the input signal is at logic 1, “TTL high,” the LED indicating leftward motion is illuminated;

when the signal is at logic 0, “TTL low,” the LED indicating rightward motion is

illuminated, specifying the direction of the voltage across the channel (and the direction

of the EOF). The signal is split between two branches, the first containing one inverter

and the other containing two inverters. Thus, the control signals at the two branches are

7

always at opposite states: when one is at logic “1,” the other is at logic “0.” Because the

particular analog switch integrated circuit utilized in this design requires an input control

signal which defines logic 1 and logic 0 at levels which are not compatible to standard

TTL logic levels, level translating circuitry consisting of diodes and resistors was utilized

to convert TTL level signals to the logic ranges required by the analog switch circuit.

Figure 8: Schematic diagram of the external voltage-switching

circuit. Five LED’s serve as indicators of the power, system modes,

and direction of the EOF. Digital signal one serves as the polarity

switch by routing the analog input voltage signal through one of two

switches that cause the signal to be multiplied by either one or

negative one. The output signals of two operational amplifiers serve

as the voltages sources for the electrodes that establish the electric

field across the channel.

Based on the states of the logic switches, the analog input voltage will either

pass through an operational amplifier, multiplying its value by negative one, or remain

unchanged. (Because digital signal one controls this function, that voltage channel

serves as the voltage polarity switch.) The analog voltage then is amplified by a factor of

1.83 through one operational amplifier and then sequentially multiplied by negative one

through another. Thus, the output electrode connector signals are at +1.83 (Vin) and 1.83 (Vin). Wires from these operational amplifier outputs are connected to gold

electrodes at each end of the channel. Hence, at one electrode, the voltage is +V and at

the other, the voltage is –V. If digital signal one (the polarity switch) changes state, the

input voltages are then multiplied by negative one, changing the direction of the EOF in

the channel.

The voltage switching circuit, DAQ board, and power supply are housed in a

metal box (see Figure 9). The LEDs are visible from the outside of the box, serving as

indicators of whether the power is on, whether the mode is “automatic” or “manual,”

whether the system is “paused” or “running,” and whether the direction of the EOF is

8

“right” or “left.” Two binding post jacks on the outside are the sources of the voltages to

be established at each end of the channel.

Figure 9: Control box containing the USB DAQ device and external

circuit. LED indicators show the status of the system, and two

binding post jacks serve as the sources of the voltage to be

established at each end of the channel.

Three-dimensional particle tracking

Due to pressure differences at each end of the channel, the fluid flow in our

PDMS microchannels may consist of both pressure-driven and electroosmotic flow. We

expect that the speed distribution of particles in the z-dimension of a channel should be

quite different for the two flow types because the driving force for EOF is generated at

the walls of the channel, whereas in the case of pressure-driven flow, the channel walls

serve as friction boundaries that limit the flow velocity. Thus, in order to fully

characterize the fluid flow profile in our PDMS microchannels, the velocity of the beads

in three dimensions must be known. By capturing videos with a camera attached to a

microscope, the velocity of beads in the focal plane may easily be measured. However,

because the beads near the bottom of the channel would require one focus setting, and

beads near the top of the channel would require a completely different focus setting, the

three-dimensional velocity profile of the beads requires a way to characterize the zposition of the bead.

One possible way to characterize the z-dependence of particle velocity would be

to collect data at many different z-values and measure the velocity of in-focus beads at

each altitude. As an alternative technique, a z-axis microscope servo system could be

developed in order to automatically bring a bead into focus, track the bead across the

field of view, and record its z-value over time.

The technique which I have investigated as part of this research involves another

methodology, in which the z-axis position of the bead used for our velocity

measurements is determined by the information encoded in the out-of-focus blur. The zcoordinate of a point source may be found by taking advantage of its point spread

function (PSF), which is defined as the response of an imaging system to a point source.

Because small fluorescent polystyrene beads are quite uniform in size (2.986 0.083

um), they are small enough to behave approximately like point sources at the

magnifications used in these experiments. A point source radiates a complete spherical

wave such that the placement of the lens intercepts a slice of the sphere (see Figure

10). The radius of the image becomes larger as the defocus increases. For even larger

displacements, the image appears as a diffraction pattern of rings, the outermost of

9

which is the brightest ring.9 Thus, the PSF of the bead may be used to identify the

distance of the bead from the focal plane.

Retrieved with permission from:

K. Seale, C. Janetopoulos, and J. Wikswo, ACS Nano 3, 493 (2009).

Figure 10: The 3-dimensional point-spead function (PSF) of a point

source. The collection cone of the microscope objective, shown

here as the “lens,” intercepts a two-dimensional slice of the PSF,

which appears as a pattern of interference rings.

Several strategies for using defocused images to determine the z-coordinate of

the particle position have been developed, including matching the radius vector of a

reference image to that of an experimental image;10 measuring the diameter of the

outermost ring of a defocused particle and using a mathematical formula to determine

the z-coordinate;11 and creating and using a calibration curve based on the radius of the

outermost ring of several reference images.12 The approach used for our data is similar

to the lattermost strategy. Each experimental image was compared to several reference

images with known z-coordinates. The z-component of the velocity may be computed

by determining which reference image matched best and performing a calculation of the

average velocity over several frames.

Initially I used convolution filters to match the reference images to the

experimental image. However, the shape of the intensity distribution prevented an

accurate match, even when normalized several different ways. Better results were

obtained by using a least squares algorithm. For example, if a reference image is

represented by a matrix with entries rij and the experimental image is represented by a

matrix with entries xij , the reference and experimental image match best when S is

minimized:

S rij xij .

2

j 1 i 1

10

To verify that the least squares matching algorithm produced accurate results, S

was computed for several experimental images with known z-coordinates. When the

reference image and experimental image corresponded to the same z-coordinate, the S

value was about an order of magnitude less than the S values for all the other images.

See Table 1 below for an example in which a five-tick image was compared with four

reference images. (The microscope used in these experiments (Zeiss Axiovert 25) has

a z-axis focusing control knob which incorporates uniformly spaced markings, or “ticks,”

which can be used as a quantitative measure of the microscope stage z-axis position.

Each “tick” corresponds to 9.6 microns above the focal plane.) Note that in Table 1,

when the z-coordinates were the same for the experimental and reference image (five

ticks), S was approximately one order of magnitude smaller than any other S value.

Least squares test: 5-tick experimental image

z of reference image

S

1 tick

237856

3 ticks

472564

5 ticks

46473

7ticks

445519

Table 1

I initially made reference images by finding the maximum pixel value (which was

usually located approximately in the center of the off-focus image) and cropping a 71-by71-pixel region of interest (ROI) around that pixel. However, when using this method,

the maximum pixel of the experimental images was often located very far from the

center of the image. To avoid this problem, I instead adopted a centroid-finding method

to determine the center of the image. The calculation shown below, in which I is

intensity, is analogous to finding the center of mass of an object:

xCM , yCM

xij I ij

I

ij

,

y I

I

ij ij

ij

.

Each centered 71-by-71 reference image was then normalized by multiplying each pixel

by 100 and dividing by the maximum value, creating an image with a maximum value of

100. Five or six reference images for each tick were averaged together to create a final

generalized reference image. This was done for z-coordinates of 0-5 ticks at half-tick

intervals (Figure 11).

11

Figure 11: Reference images and their intensity profiles used for

determining the z-value of beads imaged during our experiments.

Each tick corresponds to 4.8 microns in the vertical direction.

The matching algorithm was written as a macro for ImageJ, a Java-based image

processing package (see Appendix C). (All images must be converted to 32-bit TIFF

format prior to running the algorithm in order to avoid pixel saturation.) When the macro

is run, the user is prompted to specify the directory where the image sequence of

experimental data is located. The macro also prompts the user to choose the directory

where the reference images are located. After the first experimental image in the

sequence is opened, the user is prompted to draw a small rectangle around the bead of

interest. The macro then crops the first image down to a 71-by-71-pixel ROI centered on

the centroid of the image. The location of this ROI is saved in a new folder called “roi” in

the same directory. These files may be opened later to ensure that the program has

accurately tracked the particle. Like the reference images, each experimental image is

normalized to have a maximum value of 100. Next, each reference image in the userspecified directory is opened, and S is computed for each reference image. The

filename of the reference image for which S is a minimum is displayed in a “log” window

along with the x- and y-coordinates of the centroid. The algorithm repeats the entire

process for each experimental image in the specified directory, displaying the location of

the bead for each video frame. Using these x-, y-, and z-coordinates and the frame rate

of the video capturing software, an approximation of the particle velocity in threedimensions may then be computed.

Results and Discussion:

Initial experiments confirmed that the µ-PONG system successfully detected the

bead at each goalpost and reversed the EOF upon detection (Figure 12), allowing

experiments to run for extended periods of time. We predicted that the time the bead

12

required to travel from one goalpost to the other (the “transit time”) would remain fairly

constant over short time scales, since the attenuation of EOF should occur over several

hours.8 Since the same volume of fluid should be displaced for every transit, we also

expected that hydrodynamic flow due to differences in fluid height at the ends of the

channel would cancel out in each direction, causing no net fluid displacement. However,

our results indicated that the flow rate varies over periods of tens of seconds (Figure

13a).

Figure 12: A bead controlled by the µ-PONG system moving

between two goalposts.

Transit Time vs. Time

35

Transit Time (s)

30

25

20

15

10

5

0

0

50

100

150

200

250

300

350

400

Time (s)

Figure 13a: The time required for the bead to travel from one

goalpost to another for each transit, plotted versus time.

13

Transit time in each direction vs. time

35

30

Right

Transit Time (s)

Left

25

20

15

10

5

0

0

50

100

150

200

250

300

350

400

Time (s)

Figure 13b: The time required for the bead to travel from one goalpost to

another for each transit, plotted separately for each direction versus time.

After deconstructing the time required for the bead to travel between goalposts in

each direction (Figure 13b), it appeared that the speed of the bead decreased when

traveling to the right but increased over time when moving leftward. The bead then

approached its original speed in both directions after about 350 seconds. Further, the

decrease in speed rightward was about fifteen seconds per transit at its slowest point,

but the increase in speed leftward was always less than five seconds. We surmised that

since the initial transit times to the left and right were not equal, a net hydrodynamic flow

was present, causing the superposition of pressure-driven flow and EOF to complicate

the experiment (Figure 14). Thus, we used a syringe pump to equalize the pressure

before the start of our next trial. In the absence of EOF, the pump introduced more

buffer into the channel until the flow of beads stopped, indicating that the pressure was

equalized. However, the results indicated that although the pressure imbalance was

corrected, the transit times still varied widely throughout the experiment, much like the

first experiment (Figure 15).

PDMS

Hydrodynamic pressure

Electrode

Glass slide

_

Feof

Fh

Bead

+

Goalpost

Figure 14: Superposition of pressure-driven and electroosmotic

flow. If the height of the fluid at one end of the channel is different

from the height at the other end, the imbalance causes pressuredriven flow.

14

Transit Time vs. Time

16

Transit Time (s)

14

12

10

8

6

4

2

0

0

50

100

150

200

Time (s)

Figure 15: The time required for the bead to travel from one

goalpost to another for each transit, plotted versus time. For this

experiment, additional buffer was introduced into one end of the

channel to eliminate the pressure imbalance in the channel.

In all experiments, the bead appeared to move in all three dimensions, instead of

only in the direction parallel to the channel walls. Initially, the ImageJ plugin,

SpotTracker, was used to determine the trajectory of the bead in the channel. However,

this program required the user to click on the bead in each frame in order to compute the

velocity and contained no z-axis information, although the bead drifted out of focus,

indicating motion along the z-axis. Thus, the three-dimensional particle tracking ImageJ

macro was developed to include this information as well as automate the determination

of the x- and y-coordinate of the bead.

A reason that the bead may not only be moving along the x-axis is that, as

mentioned above, a pressure imbalance is present. Because pressure-driven flow has a

parabolic velocity flow profile while EOF has a flat profile (Figure 16), the bead may be

spinning, causing it to move in the direction of the z- and y-axis. The beads also

adhered to the channel walls after a period of about thirty minutes, indicating that

electrostatic or covalent bonds may form between the beads and the wall, perhaps

because the beads accumulate charge. As a test, three-micron carboxylated

polystyrene beads were compared with standard three-micron polystyrene beads. Many

more of the uncoated beads adhered to the channel walls than the carboxylated beads,

which adhered to the walls only after a substantially longer time, if at all. By comparison,

ten-micron polystyrene beads adhered to the walls almost immediately, suggesting that

the weight of the beads may cause sinking and adhesion. These data suggest that an

accurate characterization of the velocity profile in three dimensions is absolutely

essential.

15

Electroosmotic flow

Hydrodynamic flow

Parabolic profile

Flat profile

Figure 16: Hydrodynamic flow has a parabolic profile, while

electroosmotic flow has a flat profile.

In order to test the accuracy of the reference-matching ImageJ macro, we

decided to focus on measuring pressure-driven flow because its properties have been

well studied. Indeed, an analytical solution exists describing the velocity profile of the

fluid within a rectangular channel of a given height (height = 2b) and width (width = 2a).

In the equation of the velocity profile u(y,z),

u ( y, z )

cosh(i z / 2a) cos(i y / 2a)

16a 2 P

,

(1)(i 1) / 2 1

3

L i 1,3,5,...

i3

cosh(i b / 2a)

L is the length of the channel (0.02 meters), µ is the viscosity of water (0.00089 N/m2),

and P is the pressure difference across the channel. The measured velocities were

used to find a numerical value of P in order to calculate the theoretical profile.

Figure 17: The theoretical velocity profile is shown as a green

mesh, while the experimental data points are shown in blue. The

16

blue line is the residual between the velocity profile and

experimental data.

Residual (m/s)

Initially, the experimental data were analyzed by plotting the velocity of the beads

at each z-value (see Appendix D). Parabolas that were fit to these data demonstrate

that the velocity flow profile of the fluid flow in the channel is parabolic except at very low

z-values, due to the effects of friction at the surface of the channel. A plot of y- and zcoordinates versus velocity also demonstrated that higher velocities generally occur near

the middle of the channel, while the flow is relatively slow at the channel edges.

However, in order to fully characterize the velocity profile in three dimensions, the

theoretical velocity curve was calculated and plotted with the experimental data of the

bead velocities analyzed in the channel (see Figure 17). The measured data seemed to

be consistent with the calculated profile expect for low z-values, due to friction near the

edges. The beads at that height probably rolled along the bottom instead of moving with

the flow of the fluid. Beads with z-values greater than about twenty microns were not

observed, perhaps because the density of the beads was lower than that of water,

causing the beads to sink. Differences between the calculated profile and the

experimental data were near or below 0.0001 m/s (see Figure 18). These residuals may

be attributed to approximating the z-value to 4.8 micron intervals. However, these data

suggest that the reference-matching algorithm worked fairly well in determining the

velocity profile in three dimensions and may therefore be used to characterize EOF.

Y (meters)

Figure 18: The difference between the calculated velocity and the

velocity determined experimentally for each y-value.

To demonstrate that beads may be found at all positions in the channel, the

motion of beads flowing under hydrostatic pressure-driven force was recorded and

analyzed in an experiment in which salt water was used as a buffer. Because the

density of polystyrene is 1.05 g/mL, a solution of 10% NaCl in water was made to match

the density of the polystyrene. As shown below (Figure 19), beads were found at all

heights throughout the channel, although most beads were found near the center. This

was due to the fact that the beads move faster in the center of the channel, thereby

allowing more beads to be observed there during a given time. Hence, experiments may

17

be done with a buffer of about the same density as polystyrene so that the velocity

profile may be calculated based on beads at all z-values in the channel.

Bead Height Distribution

40

Number of Beads

35

30

25

20

15

10

5

0

0

4.8

9.6

14.4

19.2

24

28.8

33.6

38.4

43.2

48

Z (microns)

Figure 19: The number of beads observed at each z-value.

Conclusions and Future Directions:

The results of our experiments have shown that the µ-PONG system precisely

controls the movement of polystyrene beads by manipulating the electroosmotic flow

within a PDMS microchannel. The analysis software, an ImageJ macro, has proven to

be approximately accurate in determining the three-dimensional velocity profile of

pressure-driven flow in the channel. Thus, the system and analysis methods should

prove useful for characterizing EOF in the channel over time.

In the future, this system should be used to study the three-dimensional velocity

profile of EOF in the channel to characterize its attenuation over time. We expect that

the analysis of such experiments would demonstrate that pressure-driven flow and EOF

occur simultaneously. Further studies would also determine the reason that the motion

of the beads fluctuates as observed, implicating the properties of the flow. Once the

EOF is characterized for a single channel, the system may then be used to study the

fluid dynamics through more complicated microfluidic devices. This information may

then be used for designing and optimizing those devices as well as predicting the

movement of fluid within the channels.

This system may also be used to deliver fluid in a tightly controlled manner in a

microfluidic channel. Such applications may include LOC devices that require careful

control of a fluid pump. Other applications include the manipulation of micro- or

nanoscale objects, such as particles or cells. Hence, µ-PONG should serve as a

method for discovering the properties of fluid flow in microdevices and may potentially

serve as a part of other microfluidic systems for studying biology.

18

References:

1

2

3

4

5

6

7

8

9

10

11

12

S. K. Sia and G. M. Whitesides, Electrophoresis 24, 3563 (2003).

L. Cui, D. Holmes, and H. Morgan, Electrophoresis 22, 3893 (2001).

A. E. Cohen and W. E. Moerner, Physical Review Letters 98, 116001 (2007).

D. A. Skoog, F. J. Holler, and S. R. Crouch, Principles of Instrumental Analysis

(Thomson Brooks/Cole, Belmont, CA, 2007).

W. Hellmich, J. Regtmeier, T. T. Duong, R. Ros, D. Anselmetti, and A. Rox,

Langmuir 21, 7551 (2005).

G.-B. Lee, C.-H. Lin, K.-H. Lee, and Y.-F. Lin, Electrophoresis 26, 4616 (2005).

X. Y. Wang, C. Cheng, S. L. Wang, and S. R. Liu, Microfluidics and Nanofluidics 6,

145 (2009).

X. Ren, M. Bachman, C. Sims, and G. P. Li, Journal of Chromatography B 762, 117

(2001).

M. Mansuripur, Journal of the Optical Society of America A - Optics Image Science

and Vision 3, 2086 (1986).

Z. Zhang and C. Menq, Applied Optics 47, 2361 (2008).

M. Speidel, A. Jonas, and E. Florin, Optics Letters 28, 69 (2003).

S. Peterson, H. Chuang, and S. Wereley, Measurement Science & Technology 19

(2008).

19

Acknowledgements:

I would like to gratefully acknowledge Phil Samson, Dmitry Markov, and John Wikswo for

their mentorship and assistance throughout this project. I would also like to thank Dawit

Jowhar for his help in creating the LabView program by designing the imaging and

detection components of the system. Finally, I would like to acknowledge the Vanderbilt

Institute for Integrative Biosystems Research and Education, the William A. and Nancy

F. McMinn Foundation, and the Systems Biology and Bioengineering Undergraduate

Research Experience for the opportunity and funding to do this research.

20

Appendix A:

LabView Block Diagram

NO

YES

Switch polarity?

AND

Start session

MANUAL

Manual/auto mode?

AUTO

Create buffer

NO

Run?

Find connected cameras?

NO

YES

User Inputs

Control camera

settings

YES

Set min/max voltage

Send zero

volts to

channel

Acquire image

Display image

YES

Send analog

voltage to

channel

Paused?

NO

Set digital channel

Acquire intensity of

goalpost pixels

Is pixel above

threshold?

NO

(Left goalpost)

Set pixel threshold

YES

Was threshold

previously

reached at right

goalpost?

Set analog channel voltage

Save data?

NO

NO

YES

21

YES

Change state of

digital

channel one

Did state of

channel change

from previous

state?

NO

YES

Write data

to file

Is pixel above

threshold?

(Right goalpost)

AND

NO

YES

Was threshold

previously

reached at left

goalpost?

NO

YES

Appendix B: Analog Switch Datasheet

22

23

24

Appendix C: 3-D Tracking ImageJ Macro

dirSeq = getDirectory("Choose the directory where the image sequence is located");

files = getFileList(dirSeq);

File.makeDirectory(dirSeq+"\\roi")

dir = getDirectory("Choose the directory where the reference images are located");

list = getFileList(dir);

for (i=0; i<files.length; i++) {

open(dirSeq + files[i]);

currentFile = File.getName(dirSeq + files[i]);

if(i==0){

getSelectionBounds(p,q,w,h);

if(p==0){

waitForUser("Draw a small rectangle around the bead, then click

OK");

getSelectionBounds(p,q,w,h);

xcenter = round(p + w/2 - 35);

ycenter = round(q + h/2 - 35);

}

}

run("Specify ROI", "roi width=70 height=70 x="+xcenter +" y="+ycenter+" slice=1");

run("Crop");

showStatus("Finding centroid...");

width = getWidth();

height = getHeight();

yadd = 0;

xadd = 0;

total = 0;

for (y=0; y<height; y++) {

if (y%20==0) showProgress(y, height);

for (x=0; x<width; x++) {

intensity = getPixel(x,y);

xnum = intensity*x;

ynum = intensity*y;

yadd = yadd + ynum;

xadd = xadd + xnum;

total = total + intensity;

}

}

xcentroid = xadd/total;

ycentroid = yadd/total;

xcorner = round(xcentroid - 25);

ycorner = round(ycentroid - 25);

showStatus("Cropping region of interest...");

run("Specify ROI", "roi width=51 height=51 x="+xcorner+" y="+ycorner+" slice=1");

saveAs("Selection", dirSeq+"\\roi\\"+currentFile+".roi");

run("Crop");

25

showStatus("Normalizing...");

showStatus("Finding pixel with largest value...");

width = getWidth(); height = getHeight();

max=0;

for (y=0; y<height; y++) {

if (y%20==0) showProgress(y, height);

for (x=0; x<width; x++) {

value = getPixel(x,y);

if (value>max) {

max = value;

xmax = x;

ymax = y;

}

}

}

run("Divide...", "value="+max);

run("Multiply...", "value=100");

large = 1000000000;

tick = "unknown";

for (j=0; j<list.length; j++) {

open(dir + list[j]);

ref = File.getName(dir + list[j]);

imageCalculator("Difference create 32-bit", currentFile, ref);

//run("Image Calculator...", "image1="+currentFile+" operation=Difference

image2="+ref+" create 32-bit");

run("Square");

showStatus("Summing pixel values...");

width = getWidth();

height = getHeight();

for (y=0; y<height; y++) {

if (y%20==0) showProgress(y, height);

for (x=0; x<width; x++) {

value = getPixel(x,y);

sum = sum + value;

}

}

close();

close();

if (sum<large){

tick = ref;

large = sum;

}

sum = 0;

}

print(tick+","+round(xcentroid+xcenter)+","+round(ycentroid+ycenter));

close();

xcenter = xcorner + xcenter - 15;

ycenter = ycorner + ycenter - 5;

}

26

Appendix D: Preliminary Data Analysis of Pressure-Drive Flow

Velocity vs. Y for Z = 0 microns

Velocity vs. Y for Z = 14.4 microns

100

250

90

200

70

Velocity (um/s)

Velocity (um/s)

80

60

50

40

30

150

100

50

20

0

10

0

R2 = 0.3612

10

20

30

40

0

10

20

30

40

50

60

R2 = 0.9972

0

50

-50

60

Y (microns)

Y (microns)

Velocity vs. Y for Z = 19.2 microns

Velocity vs. Y for Z = 9.6 microns

250

250

200

Velocity (um/s)

150

100

150

100

50

50

0

0

R2 = 0.9864

10

20

30

-50

0

10

20

30

40

50

60

Y (microns)

Y (microns)

Velocity vs. Position

60

50

40

30

20

10

0

0

10

40

50

R2 = 0.9594

0

Z (microns)

Velocity (um/s)

200

30

20

40

50

60

-10

Y (microns)

(The area of each circle corresponds to the velocity of the bead at that position.)

27

60

28