Consideration Paper (doc)

advertisement

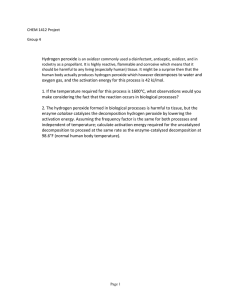

HRE08001 Hazardous Substances Consideration Committee TOPIC: Consideration of Application for the Modified Reassessment of “Ethaneperoxoic Acid, < 5% Acetic Acid and Hydrogen Peroxide” Introduction 1 Jaegar Australia Pty Ltd is seeking the modified reassessment of the substance identified as “ethaneperoxoic acid, < 5% acetic acid and hydrogen peroxide”. The substance was approved under the Hazardous Substances and New Organisms Act 1996 (“the Act”) via the Hazardous Substances (Dangerous Goods and Scheduled Toxic Substances) Transfer Notice 2004 (as amended) and has the HSNO Approval Number of HSR001479. 2 Clause 6 of the Transfer Notice states that: “No person may use a hazardous substance described in Schedules 1 and 2 to this notice as a pesticide or a veterinary medicine.” 3 The proposed modification relates to the removal of this restriction on the use of the substance as a pesticide. 4 The applicant intends that the substance will be used as a fungicide to control Botrytis on grapevines. Legislative Criteria for the Application 5 Unless otherwise stated, references to section numbers in this report refer to sections of the Act and clauses to clauses of the Hazardous Substances and New Organisms (Methodology) Order 1998 (“the Methodology”). 6 In its decision dated 20 May 2008 (Application Number: RES08001), the Authority determined that the proposed use of the substance as a pesticide is a significant change of use and therefore constitutes grounds for its reassessment (section 62(2)(c)). Consequently, the applicant is able to make an application for the modified reassessment of the substance. 7 The application was lodged on 15 August 2008 in accordance with section 63A on the basis that─ (a) (b) a reassessment of the hazardous substance under section 63 is not appropriate because the reassessment will involve only a specific aspect of the approval (i.e. the restriction on the substances use as a pesticide); and the amendment is not a minor or technical amendment to which section 67A applies (i.e. a change is use is not considered a minor or technical amendment). Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 1 of 36 8 9 The Authority may approve or decline an application for reassessment under this section, as it considers appropriate, after taking into account (see section 63A(6)): a) all the effects associated with the reassessment; and b) the best international practices and standards for the safe management of hazardous substances. When making their decision, the Authority must follow the decision path outlined in Appendix 1. Notification and Consultation 10 The Minister for the Environment was advised of the application1 and given the opportunity to “call-in” the application2. This action was not initiated. 11 The Department of Labour (Workplace Group), the New Zealand Food Safety Authority (Agricultural Compounds and Veterinary Medicines (ACVM) Group) and the Department of Conservation were identified as having a specific interest in the application and were provided with a copy of the application (excluding the confidential information but with the opportunity to access this if necessary). 11.1. 12 Other Government departments, Crown agencies and other interested parties, as listed in Appendix 5, were provided with a copy of the application summary and given the opportunity to comment or to make a submission. 12.1. 13 No comments or submissions were received. No comments or submissions were received. The application was publicly notified on the ERMA New Zealand website on 29 August 2008 and subsequently advertised in The Dominion Post, the New Zealand Herald, the Christchurch Press and the Otago Daily Times3. 12.2. No submissions were received. AGENCY EVALUATION 14 To enable the Agency to consider all the effects associated with the proposed reassessment, the Agency has undertaken an assessment of the risks, costs and benefits associated with the proposed modification to the approval of the substance. Risk Assessment 15 A “cost” is defined in Regulation 2 of the Methodology as “the value of a particular adverse effect expressed in monetary or non-monetary terms”. Thus, these have been assessed in an integrated fashion together with the risks of the adverse effects in the following assessment. 16 As the proposed modification relates to a change in use of the substance, the Agency has confined its risk assessment to the use phase of the substance’s lifecycle. 1 section 53(4)(a) section 68 3 section 53 2 Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 2 of 36 17 In accordance with sections 5 and 6 and clauses 9 and 12, the Agency has assessed the potentially non-negligible risks of the change in use of this substance in terms of risks to the environment, to human health and safety, to the relationship of Māori to the environment, to society and the community, to the market economy, and to New Zealand’s international obligations. Assessment of the risks to the environment 18 The Agency has classified “ethaneperoxoic acid, < 5% acetic acid and hydrogen peroxide” as being very toxic to the aquatic environment (9.1A) and harmful to terrestrial vertebrates (9.3C). Thus, a range of organisms in the environment may be adversely affected if exposed to the substance. 19 In addition to its ecotoxic properties, the substance has been classified by the Agency as being combustible (3.1D – low hazard). The Agency considers that there is potential for damage to the environment to occur if the substance were to be ignited at any stage of its lifecycle. However, the Agency considers that adherence to the HSNO controls on flammable substances will ensure that the level of risk to the environment associated with its flammable properties is negligible. 20 The Agency has undertaken quantitative modelling of the risks to the environment, during the proposed use of the substance as a pesticide, using the GENEEC2 model. This quantitative assessment of the risks to the aquatic environment shows that the use of the substance presents an acute risk to the aquatic environment that can be mitigated through restricted use (see Appendix 2). An estimation of the risk to the terrestrial environment was unable to be made due to a lack of available toxicity data. 21 The Agency notes the results of the quantitative modelling and considers that application of the following controls will reduce the level of risk to the environment to negligible: the approved handler controls (triggered by the 9.1A classification). The Agency considers that requiring people using the substance as a pesticide to be approved handlers, will minimise the risks associated with exposure to the aquatic and terrestrial environments; prohibiting the application of the substance into or onto water; restricting the method of application of the substance to ground-based methods only; and setting a maximum application rate, application frequency and minimum application interval. Assessment of the risks to human health and safety 22 The Agency has classified “ethaneperoxoic acid, < 5% acetic acid and hydrogen peroxide” as being an acute oral and inhalation toxicant (6.1D), a skin corrosive (8.2B) and eye corrosive (8.3A) and a target organ toxicant (6.9A). 23 The substance is also classified as presenting a low flammability hazard (3.1D) and thus has the potential to cause minimal to major adverse health effects (ranging from smoke inhalation to burns, for example). However, the Agency considers that adherence to the HSNO controls on flammable substances will ensure that the level of risk to human health associated with its flammable properties is negligible. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 3 of 36 24 The Agency did not carry out an assessment of risks to operator health using an exposure model, because of the corrosive nature of the substance. In the case of ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide, the substance is corrosive and personal protective equipment is needed to address this hazard during mixing and loading. Absorption of the active ingredients from dermal or inhalation exposure during spraying of the material is unlikely due to the use of PPE to protect the operator from the corrosive effects of the substance during mixing and loading or the irritant effects of the diluted spray if it comes into contact with the body. 25 The Agency notes that PPE is triggered as a default control for ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide as a result of its 6.1D, 8.2B, 8.3A and 6.9A classifications. 26 The Agency also considers that workers entering crops following application of the substance as a pesticide will also require PPE. Nevertheless, the Agency notes that the active ingredients degrade rapidly in the environment and considers that PPE is only likely to be needed for up to 48 hours after application. 27 The Agency has undertaken an assessment of the public health exposure and risk associated with the use of the substance as a pesticide and concludes that aerial application of the substance should be prohibited due to a concern that mist generated while the substance is being used may cause harm to people in the vicinity (see Appendix 2). Relationship of Māori to the Environment 28 The Agency has considered this application in accordance with the clauses 9(b)(i) and 9(c)(iv) and sections 6(d) and 8. In addition, the framework contained in the ERMA New Zealand user guide “Working with Māori under the HSNO Act 1996” has been used to assess the effects of this application on the relationship of Māori to the environment. 29 The Agency notes that the substance triggers a number of hazardous properties giving rise to the potential for cultural risk including the deterioration of the mauri of taonga flora and fauna species, the environment and the general health and well-being of individuals and the community. 30 In addition, the introduction and use of this substance as a pesticide has the potential to inhibit the ability of iwi/Māori to fulfil their role as kaitiaki, particularly in relation to the guardianship of waterways given the highly ecotoxic nature of the substance to aquatic species, and potential risks to the mauri ora of human health under prolonged exposure to this substance. 31 On considering the information outlined here and elsewhere in this report, the Agency considers a minimal impact from the substance on the relationship of Māori and their culture and traditions with their ancestral lands, water, sites, wāhi tapu, valued flora and fauna and other taonga to be highly improbable. In addition there is no evidence to suggest that the controlled use of the substance will breach the principles of the Treaty of Waitangi. 32 The overall level of risk is therefore considered to be negligible assuming that the substance will be handled, stored, transported, used, and disposed of, in accordance with the explicitly stated default and additional controls proposed in this report, and any other controls required by other legislation. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 4 of 36 33 However, the Agency notes that should inappropriate use, or accident, result in the contamination of waterways or the environment generally, that users notify the appropriate authorities including the relevant iwi authorities in that region. This action should include advising them of the contamination and the measures taken to contain and remediate. Assessment of the risks to society and the community 34 There are not expected to be any significant adverse impacts on the social environment with the controlled use of the substance as a pesticide, apart from the health effects and environmental effects already discussed. Consequently, the Agency considers that this aspect of potential risk need not be considered further. Assessment of the risks to the market economy 35 Taking into account the level of risk to the environment and to human welfare, no sources of additional risk have been identified that could result in an adverse economic impact on a community. 36 The Agency notes that direct economic costs will be borne by the applicant and users of the substance. The HSNO default controls intentionally do not manage direct economic effects. These are for suppliers and users of the substance to address. New Zealand’s international obligations 37 The Agency does not anticipate that the use of the substance as a pesticide will pose any risks to New Zealand’s international obligations. Assessment of Beneficial Effects 38 A “benefit” is defined in Regulation 2 of the Methodology as “the value of a particular positive effect expressed in monetary or non-monetary terms”. Benefits that may arise from any of the matters set out in clauses 9 and 11 were considered in terms of clause 13. 39 The applicant claims that the proposed modification of the approval of the substance will provide the following benefits: 40 At present there are few approved fungicides for use on mature grapes for the control or suppression of botrytis in the period immediately before harvest, due to unacceptable residues on the fruit, or the presence of disease strains resistant to specific product chemistry. Allowing the use of the substance as a pesticide will provide a new tool in the management of this damaging disease, thereby increasing the potential yield of grapevines throughout New Zealand. Increased profits and employment opportunities within Jaegar Australia Pty Ltd and those involved in the distribution of the substance within New Zealand. The Agency considers the economic and related benefits to be derived from the use of the substance as a pesticide are potentially significant. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 5 of 36 Controls 41 As a result of the proposed modification to the approval of this substance, a number of variations to the existing controls on the substance are necessary. Only those controls that are affected by the proposed modification are discussed below. A full list of controls and variations to the substance is provided in Appendix 4. Setting of exposure limits and application rates 42 Control T1 relates to the requirement to limit public exposure to toxic substances by the setting of Tolerable Exposure Limits (TELs), which are derived from Acceptable Daily Exposure (ADE) values. The Agency is not proposing that any TEL values be set for the substance at this time (see Appendix 3). 43 Control E1 relates to the requirements to limit exposure of non-target organisms in the environment through the setting of Environmental Exposure Limits (EELs). It is proposed that no EELs are set at this time for the substance and the default values are deleted (see Appendix 3). 44 Control E2 relates to the requirement to set an application rate for a class 9 substance that is to be sprayed on an area of land (or air or water) and for which an EEL has been set. As no EEL has been proposed for the substance, the Agency is not able to propose the setting of a maximum application rate under Regulation 48 of the Hazardous Substances (Classes 6, 8, and 9 Controls) Regulations 2001. However, the Agency notes that risk quotients derived from the environmental exposure modelling are above the level of concern (refer Appendix 2). This indicates that the substance may cause adverse environmental effects when used according to the specific parameters of the risk assessment. The Agency, therefore, considers it appropriate to set a maximum application rate under section 77A (see paragraph 45). Proposed additions and modifications to controls 45 The Agency notes that the risk quotients derived from the quantitative modelling indicate that restrictions on use are necessary to mitigate the risks to the environment (refer Appendix 3). Accordingly, the Agency considers that the application of controls addressing these risks will be more effective than the specified (default) controls in terms of their effect on the management, use and risks of the substance (section 77A(4)(a)). Consequently, the following additional controls are proposed for the substance to restrict the level of risk to the environment: 45.1. When used as a pesticide, the maximum application rate for ethaneperoxoic acid, < 5% acetic acid and hydrogen peroxide shall be 8625 g hydrogen peroxide and 1725 g peracetic acid per ha, with a maximum application frequency of 4 times per year and a minimum application interval of 7 days. 45.2. When used as a pesticide, the method of application of ethaneperoxoic acid, < 5% acetic acid and hydrogen peroxide shall be restricted to ground-based methods only. 45.3. Ethaneperoxoic acid, < 5% acetic acid and hydrogen peroxide shall not be applied onto or into water. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 6 of 36 46. Control E7 relates to requirements for ecotoxic substances to be under the control of an approved handler. The Agency considers that this control should be applied to the substance when it is being used as a pesticide. Accordingly, the Agency is proposing that the following control be substituted for Regulation 9(1) of the Hazardous Substances (Classes 6, 8, and 9 Controls) Regulations 2001: 46.1. “(1). The substance must be under the personal control of an approved handler when the substance is – (a) applied as a pesticide in a wide dispersive manner; or (b) used as a pesticide by a commercial contractor.” Summary of controls 47. The Agency has considered the controls imposed by the Authority in approvals given to other pesticides under Part 5 of the Act as well as those transferred to the Act under the Hazardous Substances (Pesticides) Transfer Notice 2004 (as amended) and considers that the controls listed in Appendix 4 should apply to the substance. Overall evaluation of risks, costs and benefits 48. The Agency considers the risks of the substance to the environment and human health, with the proposed controls in place, to be negligible. 49. The Agency does not consider there to be significant risks to Māori cultural wellbeing, society and the community, the market economy, or to New Zealand’s international obligations associated with the modified reassessment. 50. The Agency has taken the type and severity of the risks, and the characteristics of such risks into account, and considers that the overall level of risk posed by the substance is negligible. 51. The Agency considers that there are benefits associated with the modified reassessment of this substance as identified in paragraph 39 of this paper. 52. Thus, the Agency considers that the benefits of the modified reassessment outweigh the costs. Best international practices and standards for the safe management of hazardous substances 46 The requirement to consider best international practices and standards for the safe management of hazardous substances is demonstrated by assessing the proposed modified reassessment against: the Globally Harmonised System of Classification and Labelling of Chemicals; international codes of practice and standards; overseas legislative requirements. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 7 of 36 Globally Harmonised System 47 The controls applied to the substance as a result of the modified reassessment are based on the HSNO Regulations. These regulations specify a number of controls aimed at managing the risk posed by hazardous substances throughout their lifecycle, such as the requirement for protective clothing and provision of appropriate information, disposal and emergency management requirements. These regulations have previously met the requirements of section 141(1)(b) on best international practices and standards for the safe management of hazardous substances. In particular, the Globally Harmonised System of Classification and Labelling of Chemicals (GHS), published by the United Nations, forms the basis of the HSNO hazard classification system and the requirements for the provision of information on hazards. International Codes of Practice and Standards 48 The transportation controls on the substance requiring the segregation of incompatible substances are cross-references to the requirements of the Land Transport Rule, the Maritime Rule and the Civil Aviation Rule, which are themselves based on the International UN Transport of Dangerous Goods Model Regulations, the International Maritime Dangerous Goods Code and the International Civil Aviation Organization Regulations. Overseas Legislative Requirements 49 The Agency notes that the substance is approved for use as a pesticide by a number of overseas regulators, including the Australian Pesticides and Veterinary Medicines Authority (APVMA). The controls proposed by the Agency are consistent with those imposed by the APVMA. Conclusions 50 Jaegar Australia Pty Ltd is seeking the modified reassessment of the substance identified as “ethaneperoxoic acid, < 5% acetic acid and hydrogen peroxide” to allow its use as a pesticide. 51 The Agency considers that there are negligible risks to the environment and human health, with the proposed controls in place, and benefits associated with the modified reassessment of the substance. 52 The Agency considers that the modified reassessment meets the requirements of best international practices and standards for the safe management of hazardous substances. 53 The Agency considers that the application for the modified reassessment meets the requirements of section 63A(6) and, therefore, may be approved in accordance with clause 26. 54 The Agency considers that the controls listed in Appendix 4 should apply to ethaneperoxoic acid, < 5% acetic acid and hydrogen peroxide. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 8 of 36 APPENDIX 1 DECISION PATH Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 9 of 36 APPENDIX 2 RISK ASSESSMENT Environmental exposure and risk assessment For Class 9 substances, irrespective of the intrinsic hazard classification, the ecological risk can be assessed for a substance by calculating a risk quotient based on an estimated exposure concentration. Such calculations incorporate toxicity values, exposure scenarios (including spray drift, application rates and frequencies), and the half lives of the component(s) in soil and water. The calculations provide an Estimated Environmental Concentration (EEC) which, when divided by the LC50 or EC50, gives a risk quotient (RQ). Acute RQ = EECshort term LC50 or EC50 Chronic RQ = EEClong term NOEC If the RQ exceeds a predefined level of concern, this suggests that it may be appropriate to refine the assessment or to apply the approved handler (AH1) control and/or other controls to ensure that appropriate matters are taken into account to minimize off-site movement of the substance. Conversely, if a worst-case scenario is used, and the level of concern is not exceeded, then in terms of the environment, there is a presumption of low risk which is able to be adequately managed by such things as label statements (warnings, disposal). The AH1 control can then be removed on a selective basis. Levels of concern (LOC) developed by the US EPA (Urban and Cook 1986) and adopted by the Agency, to determine whether a substance poses an environmental risk are provided in Table A2.1. Table A2.1: Levels of concern as adopted by the Agency. Endpoint LOC Presumption Aquatic (fish, invertebrates) Acute RQ≥ 0.5 High acute risk Acute RQ 0.1-0.5 Risk can be mitigated through restricted use Acute RQ< 0.1 Low risk Chronic RQ≥ 1 High chronic risk Plants (aquatic and terrestrial) Acute RQ≥ 1 High acute risk Mammals and birds Acute dietary 0.5 RQ≥ Acute oral dose 0.5 [granular products] RQ≥ Chronic RQ≥ 1 High acute risk High acute risk High chronic risk Aquatic risk The Agency used the application rate and frequency information of Peratec Fungicide to assess the risks. This product is just one of the products that is covered by the approved substance described as Ethaneperoxoic acid, < 5% in acetic acid and hydrogen peroxide. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 10 of 36 Assessment of Expected Environmental Concentration The Agency has used the Generic Estimated Environmental Concentration Model v2 (GENEEC2) surface water exposure model (US EPA 2001) to estimate the EEC of hydrogen peroxide and peracetic acid in surface water which may potentially arise as a result of spray drift and surface runoff from the applicant’s proposed New Zealand use pattern. The parameters of hydrogen peroxide used in the GENEEC2 modeling are listed in Table A2.2 and represent the recommended use on grapes. Table A2.2: Input parameters of hydrogen peroxide for GENEEC2 analysis. Application rate hydrogen peroxide 8.625 kg ai/ha Application frequency 4 Application interval 7 days Koc 1.58 (log Koc= 0.2) Aerobic soil DT50 0.625 days Pesticide wetted in? no Methods of application Option 1: airblast Reference Label information of Peratec Fungicide provided by Jaeger Australia Pty Ltd EU risk assessment report 2003; hydrogen peroxide EU risk assessment report 2003; hydrogen peroxide Option 2: aerial application ‘No spray’ zone 0 Water solubility Miscible in water (estimated value 10,000) Aerobic aquatic DT50 5 days EU risk assessment report 2003; hydrogen peroxide Aqueous photolysis DT50 0.833 days Degussa AG Frankfurt am Main [IUCLID] Output from the GENEEC2 model. Hydrogen peroxide Option 1: Airblast RUN No. 1 FOR hydrogen ON grapes * INPUT VALUES * -------------------------------------------------------------------------------------------------------RATE (lb/AC) No.APPS & SOIL SOLUBIL APPL TYPE NO-SPRAY INCORP ONE(MULT) INTERVAL Koc (PPM ) (%DRIFT) (FT) (IN) -------------------------------------------------------------------------------------------------------7.679( 7.682) 4 7 1.610000.0 VINYAR( 1.5) .0 .0 Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 11 of 36 FIELD AND STANDARD POND HALFLIFE VALUES (DAYS) --------------------------------------------------------------------------------------------------METABOLIC DAYS UNTIL HYDROLYSIS PHOTOLYSIS METABOLIC COMBINED (FIELD) RAIN/RUNOFF (POND) (POND-EFF) (POND) (POND) ---------------------------------------------------------------------------------------------------.63 2 N/A .83- 103.29 5.00 4.77 GENERIC EECs (IN MICROGRAMS/LITER (PPB)) Version 2.0 Aug 1, 2001 --------------------------------------------------------------------------------------------------PEAK MAX 4 DAY MAX 21 DAY MAX 60 DAY MAX 90 DAY GEEC AVG GEEC AVG GEEC AVG GEEC AVG GEEC -------------------------------------------------------------------------------------------------57.29 51.60 29.29 12.50 8.40 Option 2: aerial RUN No. 2 FOR hydrogen ON grapes * INPUT VALUES * ---------------------------------------------------------------------------------------------------------RATE (lb/AC) No.APPS & SOIL SOLUBIL APPL TYPE NO-SPRAY INCORP ONE(MULT) INTERVAL Koc (PPM ) (%DRIFT) (FT) (IN) --------------------------------------------------------------------------------------------------------7.679( 7.682) 4 7 1.610000.0 AERL_B( 13.0) .0 .0 FIELD AND STANDARD POND HALFLIFE VALUES (DAYS) --------------------------------------------------------------------------------------------------METABOLIC DAYS UNTIL HYDROLYSIS PHOTOLYSIS METABOLIC COMBINED (FIELD) RAIN/RUNOFF (POND) (POND-EFF) (POND) (POND) --------------------------------------------------------------------------------------------------.63 2 N/A .83- 103.29 5.00 4.77 GENERIC EECs (IN MICROGRAMS/LITER (PPB)) Version 2.0 Aug 1, 2001 -------------------------------------------------------------------------------------------------PEAK MAX 4 DAY MAX 21 DAY MAX 60 DAY MAX 90 DAY GEEC AVG GEEC AVG GEEC AVG GEEC AVG GEEC -----------------------------------------------------------------------------------------------136.15 126.13 72.11 30.80 20.69 The Estimated Environmental Concentration (EEC) for hydrogen peroxide as estimated by GENEEC2 are: Peak EEC : airblast 0.05729 mg/l, aerial 0.13615 mg/l Chronic EEC (21 days): airblast 0.02929 mg/l, aerial 0.07211 mg/l Assessment of acute risk The Estimated Environmental Concentration (EEC) for hydrogen peroxide as estimated by GENEEC2 are shown in Table A2.3, along with the aquatic data for hydrogen peroxide for the most sensitive species tested (further details on these toxicity data are included in Table A2.4). The acute toxicity values used for the risk assessment are shown in Table A2.3. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 12 of 36 Table A2.3: Aquatic Ecotoxicity endpoints to be used in risk assessment. Fish 96 h semistatic LC50= 16.4 mg/L 48 h semistatic EC50 =2.4 mg/L Pimephales promelas Invertebrates Shurtleff LE (1989). Interox America Sodium Percarbonate and Hydrogen Peroxide - Acute Toxicity to the Freshwater Fish Pimephales Promelas. Burlington Research, INC, Burlington, North Carolina, USA. Shurtleff LE (1989). Interox America Sodium Percarbonate and Hydrogen Peroxide - Acute Toxicity to the Daphnia pulex Freshwater Invertebrate Daphnia Pulex. Burlington Research, INC., Burlington, North Carolina, USA. Algae/ 72h EbC50 =2.5 mg/L Aquatic plants Degussa AG (1991). Algenwachstumshemmtest mit Wasserstoffperoxid 35% G. Geschäftsbereich Industrie- und Feinchemikalien, Frankfurt am Main. Chlorella vulgaris Table A2.4: Acute risk quotients derived from the GENEEC2 model and toxicity data. Peak EEC from LC50 or EC50 RQ (Acute) GENEEC2 (mg/L) (mg/L) EEC/ LC50 or EC50 airblast 0.05729 Fish 16.4 0.0035 Crustacea 2.4 0.024 Algae 2.5 0.023 Fish 16.4 0.0083 Crustacea 2.4 0.057 Algae 2.5 0.054 0.13615 aerial When compared against the relevant acute levels of concern (Table A2.1), the acute RQs derived from the GENEEC2 modeling for hydrogen peroxide indicate the acute risk for aquatic organisms is low. There is no difference between the application methods. As no chronic ecotoxicity data was available for hydrogen peroxide, no estimation of chronic risk was able to be made. The parameters of peracetic acid used in the GENEEC2 modeling are listed in Table A2.5 and represent the recommended use on grape. Table A2.5: Input parameters of peracetic acid for GENEEC2 analysis. Application rate Application frequency Peracetic acid 1.725 kg ai/ha 4 Reference Label information of Peratec Fungicide provided by Jaeger Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 13 of 36 Application interval 7 days Australia Pty Ltd Koc 4 Meylan WM et al, Environmental Science & Technology 26;1560-67 (1992) Aerobic soil DT50 0 default Pesticide wetted in? no Methods of application Option 1: airblast Option 2: aerial application ‘No spray’ zone 0 Water solubility ≥ 100 mg/L at 19oC (very soluble) Aerobic aquatic DT50 3 days Aqueous photolysis DT50 0 default information provided by Jaeger Australia Pty Ltd ECETOC (2001) Peracetic acid (cas no 7921-0) and its equilibrium solutions. JACC no. 40 ECETOC Brussels 2001 Output from the GENEEC2 model. Peracetic acid Option 1: airblast RUN No. 3 FOR peracetic ON grapes * INPUT VALUES * --------------------------------------------------------------------------------------------RATE (lb/AC) No.APPS & SOIL SOLUBIL APPL TYPE NO-SPRAY INCORP ONE(MULT) INTERVAL Koc (PPM ) (%DRIFT) (FT) (IN) -------------------------------------------------------------------------------------------1.536( 6.143) 4 7 4.0 100.0 VINYAR( 1.5) .0 .0 FIELD AND STANDARD POND HALFLIFE VALUES (DAYS) ------------------------------------------------------------------------------------------------------METABOLIC DAYS UNTIL HYDROLYSIS PHOTOLYSIS METABOLIC COMBINED (FIELD) RAIN/RUNOFF (POND) (POND-EFF) (POND) (POND) -------------------------------------------------------------------------------------------------------.00 2 N/A .00- .00 3.00 3.00 GENERIC EECs (IN MICROGRAMS/LITER (PPB)) Version 2.0 Aug 1, 2001 ------------------------------------------------------------------------------------------------PEAK MAX 4 DAY MAX 21 DAY MAX 60 DAY MAX 90 DAY GEEC AVG GEEC AVG GEEC AVG GEEC AVG GEEC -----------------------------------------------------------------------------------------------340.96 284.75 126.67 47.61 31.76 Option 2: aerial RUN No. 4 FOR peracetic ON grapes * INPUT VALUES * Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 14 of 36 ---------------------------------------------------------------------------------------------RATE (lb/AC) No.APPS & SOIL SOLUBIL APPL TYPE NO-SPRAY INCORP ONE(MULT) INTERVAL Koc (PPM ) (%DRIFT) (FT) (IN) --------------------------------------------------------------------------------------------1.536( 6.143) 4 7 4.0 100.0 AERL_B( 13.0) .0 .0 FIELD AND STANDARD POND HALFLIFE VALUES (DAYS) ---------------------------------------------------------------------------------------------------METABOLIC DAYS UNTIL HYDROLYSIS PHOTOLYSIS METABOLIC COMBINED (FIELD) RAIN/RUNOFF (POND) (POND-EFF) (POND) (POND) -------------------------------------------------------------------------------------------------.00 2 N/A .00- .00 3.00 3.00 GENERIC EECs (IN MICROGRAMS/LITER (PPB)) Version 2.0 Aug 1, 2001 -----------------------------------------------------------------------------------------------PEAK MAX 4 DAY MAX 21 DAY MAX 60 DAY MAX 90 DAY GEEC AVG GEEC AVG GEEC AVG GEEC AVG GEEC ------------------------------------------------------------------------------------------------338.33 283.43 126.18 47.43 31.64 The Estimated Environmental Concentration (EEC) for peracetic acid as estimated by GENEEC2 are: Peak EEC : airblast 0.34096 mg/l, aerial 0.33833 mg/l Chronic EEC (21 days) airblast 0.12667 mg/l, aerial 0.12618 mg/l Assessment of acute risk The Estimated Environmental Concentration (EEC) for peracetic acid as estimated by GENEEC2 are shown in Table A2.7, along with the aquatic data for peracetic acid for the most sensitive species tested (further details on these toxicity data are included in Table A2.6). It was hard to find toxicity information and the figures quoted are the most applicable figures to Peratec Fungicide. Table A2.6: Aquatic Ecotoxicity endpoints to be used in risk assessment. Fish 96 h Lepomis macrochirus 5.2% peracetic acid, 20% hydrogen peroxide, not stated HOAc ECETOC (2001) Peracetic acid (cas no 79-21-0) and its equilibrium solutions. JACC no. 40 ECETOC Brussels 2001 LC50 = 1.1 mg peracetic acid/L Invertebrates Daphnia magna 48 h Composition 15% peracetic acid, 14% hydrogen peroxide, 28% HOAc ECETOC (2001) Peracetic acid (cas no 79-21-0) and its equilibrium solutions. JACC no. 40 ECETOC Brussels 2001 EC50 = 0.5 mg peracetic acid/L 5.2% peracetic acid, 20% hydrogen peroxide, not stated Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 15 of 36 HOAc EC50 = 0.73 mg peracetic acid/L Algae/ 72h Aquatic plants ECETOC (2001) Peracetic acid (cas no 79-21-0) and its equilibrium solutions. JACC no. 40 ECETOC Brussels 2001 Composition 18% peracetic acid, 0.3 % hydrogen peroxide, not stated HOAc Selenastrum capricornutum EC50 <1.0 mg peracetic acid Table A2.7: Acute risk quotients derived from the GENEEC2 model and toxicity data. Peak EEC from LC50 or EC50 RQ (Acute) GENEEC2 (mg/L) (mg/L) EEC/ LC50 or EC50 airblast 0.34096 Fish 1.1 0.310 Crustacea 0.73 0.467 Algae 1 0.341 Fish 1.1 0.308 Crustacea 0.73 0.463 Algae 1 0.338 0.33833 aerial When compared against the relevant acute levels of concern (Table A2.1), the acute RQs derived from the GENEEC2 modeling for peracetic acid indicate the following: For fish, crustacean and algae: the acute risk can be mitigated through restricted use. There is no difference between the application methods. Assessment of chronic risk As no chronic ecotoxicity data was available for peracetic acid, no estimation of chronic risk was able to be made. Conclusion aquatic risk Based on the acute RQs for fish and crustacean, the Agency considers it appropriate to retain the approved handler controls when the substance is used in a wide dispersive manner, or by a commercial contractor. Further, the Agency considers that the application rate proposed by the applicant and used in the modeling should be set as a maximum application rate. Terrestrial risk With respect to the risk to the terrestrial environment, no estimation of this risk was able to be made due to the lack of available toxicity data. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 16 of 36 Overall conclusion for Ethaneperoxoic acid, < 5% in acetic acid and hydrogen peroxide Based on the use pattern of Peratec Fungicide the Agency considers there is a potential risk for aquatic organisms when Ethaneperoxoic acid, < 5% in acetic acid and hydrogen peroxide is used in a wide dispersive manner. Due to a lack of terrestrial ecotoxicity data the Agency was not able to assess the risk to terrestrial organisms neither for Peratec Fungicide nor for Ethaneperoxoic acid, < 5% in acetic acid and hydrogen peroxide. Due to the outcome of the risk assessment the Agency proposes to set additional controls when the substance is used in a wide dispersive manner (see Appendix 3). At this stage the Agency is not able to set extra controls to deal with the uncertainties with regard to terrestrial organisms as this has been the policy of the Agency for similarly applied products. Human health risk assessment Operator exposure assessment The Agency did not carry out an assessment of risks to operator health using an exposure model, because of the corrosive nature of the substance. The United Kingdom Pesticide Safety Directorate’s interpretation of the German BBA Model estimates operator exposure to active ingredients during the use of the substance. This model estimates the exposure of workers to a pesticide during mixing, loading and during spray application, in mg/kg person/day (http://www.pesticides.gov.uk/index.htm). In the case of ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide, the substance is corrosive and personal protective equipment is needed to address this hazard during mixing and loading. Absorption of the active ingredients from dermal or inhalation exposure during spraying of the material is unlikely due to the use of PPE to protect the operator from the corrosive effects of the substance during mixing and loading or the irritant effects of the diluted spray if it comes into contact with the body. The derivation of an acceptable operator exposure limit (AOEL) was not appropriate, and no comparison of the systemic exposure against a derived AOEL was carried out. In the case of a corrosive/irritant substance it is not the absorption of the active ingredient which causes the hazard, so use of an AOEL is not appropriate. The Agency notes that the use of appropriate PPE is essential when handling the concentrate and when applying the diluted substance due to the corrosive nature of the active ingredients. It is necessary to protect the operator from the skin and eye corrosivity of the substance and from the harmful effects of inhalation of the mist. The Agency notes that PPE is triggered as a default control for ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide as a result of its 6.1D, 8.2B, 8.3A and 6.9A classifications. The Agency also considers that workers entering crops following application of Peratec will also require PPE. Nevertheless, the Agency notes that the active ingredients degrade rapidly in the environment and considers that PPE is only likely to be needed for up to 48 hours after application. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 17 of 36 Public health exposure and risk assessment The main potential source of exposure to the general public from ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide (other than via food residues which will be considered as part of the registration of this substance under the Agricultural Compounds and Veterinary Medicines (ACVM) Act 1997) is via spray drift. Although no operator exposure modeling was done for ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide, the Agency assumes that operators from are required to wear PPE to protect against the corrosive nature of the substance. The Agency notes that any potential bystanders will not be wearing PPE, but they will not be directly handling the substance during mixing and loading. The bystanders are only likely to be exposed to the diluted material which is an irritant, not corrosive. Applications will need to be done under suitable weather conditions to minimise spray drift into areas where bystanders may be present. The applicant proposed that the application would be made using ground-based methods. The Agency considered the possibility that aerial application of formulations covered by the description ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide might be undertaken if aerial application is not proscribed. The Agency notes that undiluted material is both a skin and eye corrosive. After dilution 1:50 in water, the diluted material would be a skin and eye irritant. Bearing in mind the proximity of some crop areas to places where members of the public may legally be during spraying, the Agency recommends the addition of a control that prohibits aerial application of the product, due to concern that mist may cause harm to people in the vicinity. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 18 of 36 APPENDIX 3 DISCUSSION ON CONTROLS Toxicity Controls Setting of TELs (Control Code T1) Tolerable Exposure Limits (TELs) are designed to limit the extent to which the general public is exposed to hazardous (toxic) substances. A TEL represents the maximum concentration of a substance legally allowable in a particular medium, and can be set as either a guideline value or an action level that should not be exceeded. For the purposes of setting TELs, an environmental medium is defined as air, water, soil or a surface that a hazardous substance may be deposited onto. TELs are established from PDE (potential daily exposure) values, which are themselves established from ADE (acceptable daily exposure) values or reference doses (RfD) which are similar to an ADE but are used to protect against a specific toxic effect of concern. Human exposure may also occur through food or drinking water. Exposure through food is managed via the establishment of Maximum Residue Limits (MRLs) as set by the Minister of Food Safety on the advice of the New Zealand Food Safety Authority (NZFSA). Exposure through drinking water is managed via the establishment of Maximum Acceptable Values (MAVs) as set by the Ministry of Health. MRLs and MAVs are also established from ADE values. Setting of PDEs If an ADE or RfD value is set for a substance, or component of a substance, a PDE value for each relevant exposure route must also be set. A PDE is an amount of substance (mg/kg bodyweight/day), calculated in accordance with Regulation 23, that estimates the relative likelihood of particular exposures. A PDE for any single exposure route is a fraction of the ADE or RfD, and the sum of all PDE values from all possible exposures must be less than or equal to the ADE or RfD. The main routes of exposure considered are ingestion (food, water, air, soil), inhalation (air) and skin contact (surface deposition, water, soil). Setting of ADEs An ADE is an amount of a hazardous substance (mg/kg bodyweight/day), that, given a lifetime of daily exposure, would be unlikely to result in adverse human health effects. An RfD (reference dose) is a similar measure that can be used to protect against a specific toxic effect of concern. Regulation 11(1) of the Hazardous Substances (Classes 6, 8, and 9 Controls) Regulations 2001 determines when an ADE/RfD is required to be set: (1) This regulation applies to a class 6 substance if(a) it is likely to be present in(i) 1 or more environmental media; or (ii) food; or Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 19 of 36 (b) (c) effect. (iii) other matter that might be ingested; AND it is a substance to which a person is likely to be exposed on 1 or more occasions during the lifetime of the person; AND exposure to the substance is likely to result in an appreciable toxic If all three requirements of regulation 11(1) are met, then an ADE/RfD should be set for the relevant component(s), and PDE and TEL values subsequently established for each relevant exposure route. The toxicity (Class 6) classifications of ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide that trigger the need to consider setting a TEL are 6.1D, 8.2B, 8.3A, 6.9A. Where a substance is a pesticide or veterinary medicines active ingredient that is new to New Zealand and it is intended for use on a food crop or animal, the Agency usually proposes an ADE regardless of whether the requirements of Regulation 11 are met as this information may be of use to NZFSA in setting MRLs. The Agency notes that due to the chemical reactivity of the peroxy derivatives the active ingredients will break down rapidly, so that it is unlikely that it is necessary for ACVM to establish MRLs. The Agency notes that this view is supported by the observation that MRLs have not been set for peracetic acid or hydrogen peroxide by the US EPA due to the high reactivity and rapid degradation of these components. This is the case, even though they are used as sanitisers in food processing plants (EPA, RED, Peroxy compounds, 1993). Therefore, the Agency proposes not to set ADEs, PDEs or TELS for any components of the substance at this time. Setting of WES (Control Code T2) Workplace exposure standards (WES) are designed to protect persons in the workplace from the adverse effects of toxic substances. A WES is an airborne concentration of a substance (expressed as mg substance/m3 of air, or ppm in air), which must not be exceeded in a workplace and only applies to places of work (Regulation 29(2), Hazardous substances (Classes 6, 8, and 9 Controls) Regulations 2001). Regulation 29(1) of the Hazardous Substances (Classes 6, 8 and 9 Controls) Regulations 2001 determines when a WES is required to be set. If all three of the requirements of this regulation are met then a WES is required to be set. Regulation 29 states: (1) This regulation and regulation 30 apply to a class 6 substance if,(a) under the temperature and pressure the substance is to be used in, it can become airborne and disperse in air in the form of inspirable or respirable dust, mists, fumes, gases or vapours; AND (b) human exposure to the substance is primarily through the inhalation or dermal exposure routes; AND (c) the toxicological and industrial hygiene data available for the substance is sufficient to enable a standard to be set. When setting WES, the Authority must either adopt a value already proposed by the Department of Labour or already set under HSNO or derive a value by taking into account the Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 20 of 36 matters described in Regulation 30(2) of the Hazardous Substances (Classes 6, 8 and 9 Controls) Regulations. The Agency typically adopts WES values listed in the Workplace Exposure Standards (Effective from 2002) document (refer to the link below). http://www.osh.govt.nz/order/catalogue/pdf/wes2002.pdf The Agency notes that Department of Labour and/or HSNO WES values have been set for peracetic acid and hydrogen peroxide in “Ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide” and that these values were adopted in clause 7 of the Notice. The Agency confirms that the WES values should continue to apply to the substance. The values are listed in Table A3.1. Table A3.1 - WES values for components of Ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide. Component WES TWA@ WES STEL@ 3 Acetic acid 10 ppm 25 mg/m 15 ppm 37 mg/m3 (CAS 64-19-7) Hydrogen 1 ppm 1.4 mg/m3 -# -# peroxide (CAS 7722-84-1) @ TWA # = time weighted average, STEL = short term excursion limit. No WES STEL value has been established. The Agency notes that the DOL booklet lists hydrogen peroxide as an “A3 Carcinogen”. The Agency did not consider it appropriate to review the class 6.7 classification for hydrogen peroxide based on this information at this time. This application is only considering hydrogen peroxide in the context of its presence in a particular mixture with peracetic acid, and the application considers the implications for its horticultural use. A review of the carcinogenicity of hydrogen peroxide should consider approvals for other formulations of the substance. WES values for other components in ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide may be reviewed at a later date under s77B of the Act. Ecotoxicity Controls Setting of EELs (Control code E1) Regulation 33 of the Hazardous Substances (Classes 6, 8, and 9 Controls) Regulations 2001 specify that an environmental exposure limit (EEL) may be set for a class 9 substance for one or more environmental media if organisms that live in that environment may be exposed to the substance. An EEL is the (maximum) concentration of a substance in an environmental medium that will present a negligible risk of adverse environmental effects to organisms (excluding humans) in non-target areas. As specified by regulation 32, a default EEL of 0.1 µg/L water is set for any class 9.1 substance, and 1 µg/kg soil (dry weight) for any class 9.2 substance. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 21 of 36 For the purposes of setting EELs, an environmental medium is defined as water, soil or sediment where these are in the natural environment, or a surface onto which a hazardous substance may be deposited. An EEL can be established by one of three means: Applying the default EELs specified in regulation 32 Adopting an established EEL as provided by regulation 35(a) Calculating an EEL from an assessment of available ecotoxicological data as provided by regulation 35(b). The Hazardous Substances and New Organisms (Approvals and Enforcement) Act 2005 added a new section (s77B) to the HSNO Act, which, amongst other things provided the Authority with the ability to set EELs as guideline values, rather than the previous pass/fail values. However, until the Agency has developed formal policy on the implementation of s77B, it proposes not to set EELs for ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide at this time. It is also proposed that the default EEL water value be deleted until the policy has been established. Approved Handler Controls- Highly ecotoxic substances (AH1, E7) Approved handler requirements have been triggered for ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide as a result of its 9.1A classification. The outcome of the ecological risk assessment (refer Appendix 2) indicates that there is potential for acute adverse environmental effects on aquatic organisms if the substance moves off-target (i.e. RQ > LOC). The Agency considers it is therefore appropriate to retain the approved handler control as provided by section 77(3)(a). This approach is consistent with the Authority’s policy on approved handler and tracking controls for class 9 substances (November 2003). Setting of Application Rate (Control Code E2) These regulations relate to the requirement to set an application rate for a class 9 substance that is to be sprayed or applied to an area of land (or air or water) and for which an EEL has been set. Although no EEL has been set for ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide, the Agency proposes setting the maximum application rate of 8625 g hydrogen peroxide and 1725 g peracetic acid per ha. The maximum application frequency per year is 4 with an interval of 7 days. This rate was used in the ecological risk assessment. Other controls required as a result of the ecological risk assessment This substance is not to be applied onto or into water. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 22 of 36 Identification controls Identification of Toxic and/or Corrosive Components on Labels/Documentation (SDS) The Hazardous Substances (Identification) Regulations 2001 specify that certain toxic and/or corrosive components are required to be specified on the product label and on SDS documentation. Identification of toxic components on labels Regulations 25(e) and 25(f) require that certain toxic components are required to be specified on the product label. Regulation 25(e) states: ...a toxic substance must be identified by... 'information identifying, by its common or chemical name, every ingredient, that would, independently of any other ingredient, give the substance a hazard classification of 6.1A, 6.1B, 6.1C, 6.5, 6.6, 6.7, 6.8 or 6.9, and the concentration of that ingredient in the substance." Regulation 25(f) states: ...a toxic substance must be identified by... "information identifying (other than an ingredient referred to in paragraph (E)) that would, independently of any other ingredient, give the substance a hazard classification of 6.1D, and the concentration of the ingredient that would contribute the most to that classification." Identification of corrosive components on labels Regulation 19(f) requires that certain corrosive components are required to be specified on the product label. Regulation 19(f) states: ...a corrosive substance must be identified by... "If the substance contains any ingredient in such a concentration that the ingredient would, independently of any other ingredient, cause the substance to be classified as class 8.2 or class 8.3, in respect of each such ingredient,(i) its common or chemical name; and (ii) a statement of its concentration in the substance.” Identification of toxic and/or corrosive components on SDS Regulation 39(5) of the Hazardous Substances (Identification) Regulations 2001, states that certain corrosive and toxic components are required to be specified on documentation. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 23 of 36 Regulations 39(5) states: "The requirements of regulation 19(f) or (as the case requires) regulation 25(e) apply to all documentation; but any ingredient required by that provision to be identified (other than an ingredient to which regulation 26 applies) must also be identified by any Chemical Abstract Services number allocated to it." Concentration cut-offs for component identification Consistent with the guidance provided by GHS, the Hazardous Substances Standing Committee (HSSC) agreed that the concentration cut-offs triggering the requirement for identification of components on labels and documentation are: HSNO Classification 6.5A, 6.5B, 6.6A, 6.7A 6.6B 6.7B 6.8A, 6.8C 6.8B 6.9A, 6.9B Cut-off for label (% w/w) Cut-off for SDS (% w/w) 0.1 0.1 1 1 1 0.1 0.3 0.1 3 0.1 10 1 Ethaneperoxoic acid, <5% in acetic acid and hydrogen peroxide - Components requiring identification Under these regulations, as determined by the HSSC (March 2006), the name and concentration of the following components need to be specified on the label and documentation: Label Peracetic Acid Hydrogen peroxide Documentation Peracetic Acid Hydrogen peroxide Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 24 of 36 APPENDIX 4: LIST OF REVISED CONTROLS FOR ETHANEPEROXOIC ACID, < 5% ACETIC ACID AND HYDROGEN PEROXIDE Table A4.1: Revised controls for ethaneperoxoic acid, < 5% acetic acid and hydrogen peroxide – codes, regulations and variations. Control Regulation5 Topic Variations Code4 Hazardous Substances (Classes 1 to 5 Controls) Regulations 2001 F2/O2 8 General public transportation restrictions and requirements for all class 1 to 5 substances F6 60-70 Requirements to prevent unintended ignition of class 2.1.1, 2.1.2 and 3.1 substances F11 76 Segregation of incompatible substances O1 7 General test certification requirements for hazardous substance locations O3 88 General limits on class 5.1.1 and 5.1.2 substances O4 89 Approved handler/security requirements for certain class 5.1.1 and 5.1.2 substances Controls F2, O2 and T7 are combined. Exception to approved handler requirement for transportation of packaged substances (1) Regulation 89 is deemed to be complied with if— (a) in the case of a hazardous substance being transported on land— (i) in the case of a hazardous substance being transported by rail, the person who drives the rail vehicle that is transporting the substance is fully trained in accordance with the approved safety Note: The numbering system used in this column relates to the coding system used in the ERMA New Zealand Controls Matrix. This links the hazard classification categories to the regulatory controls triggered by each category. It is available from the ERMA New Zealand website www.ermanz.govt.nz/resources and is also contained in the ERMA New Zealand User Guide to the HSNO Control Regulations. 5 These Regulations form the controls applicable to this substance. Refer to the cited Regulations for the formal specification, and for definitions and exemptions. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 25 of 36 4 Control Code4 Regulation5 Topic Variations system under section 6D of the Transport Services Licensing Act 1989 or a safety system which is referred to in an approved safety case under the Railways Act 2005; and (ii) in every other case, the person who drives, loads, and unloads the vehicle that is transporting the substance— (A) for hire or reward, or in quantities that exceed those set out in Schedule 1 of the Land Transport Rule 45001/1: Dangerous Goods 2005, has a current dangerous goods endorsement on his or her driver’s licence; or (B) in every other case, the Land Transport Rule 45001/1: Dangerous Goods 2005 is complied with; or (b) in the case of a hazardous substance being transported by Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 26 of 36 Control Code4 Regulation5 Topic Variations sea, one of the following is complied with: (i) Maritime Rules: Part 24A – Carriage of Cargoes – Dangerous Goods (MR024A); or (ii) International Maritime Dangerous Goods Code; or (c) in the case of a hazardous substance being transported by air, Part 92 of the Civil Aviation Rules is complied with. (2) Subclause (1)(a)— (a) does not apply to a tank wagon or a transportable container to which the Hazardous Substances (Tank Wagons and Transportable Containers) Regulations 2004 applies; but (b) despite paragraph (a), does apply to an intermediate bulk container that complies with chapter 6.5 of the UN Model Regulations. (3) Subclause (1)(c)— (a) applies to pilots, aircrew, and airline ground personnel loading and handling a hazardous substance within an aerodrome; but (b) does not apply to the storage and handling of a hazardous substance in any place that is not within an aerodrome, or within an aerodrome by non-airline ground personnel. (4) In this regulation, UN Model Regulations means the 14th revised Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 27 of 36 Control Code4 Regulation5 Topic Variations edition of the Recommendation on the Transport of Dangerous Goods Model Regulations, published in 2005 by the United Nations. O5 91 Requirements to prevent unintended combustion or explosion of class 5.1.1 and 5.1.2 substances O6 92 Requirements for protective clothing and equipment O7 93 Requirements to control adverse effects of spills or failure of containers O8 94 - 97 Controls on hazardous substance locations where class 5.1.1 or 5.1.2 substances are present This regulation applies to this substance as if, in regulation 95(1)(c), the words “but excluding electrical equipment” were inserted after the words “ignition sources”. This regulation applies to this substance as if regulation 95(1)(f) was replaced by: (f) The location is designed and managed so that any moisture or any vapour, gas, or particulate matter of class 5.1.1 or 5.1.2 substances does not present a hazard in respect of electrical equipment that may be present. O9 98 - 100 Test certification requirements for hazardous substance locations where class 5.1.1 or 5.1.2 substances are present O10 101 Controls on transit depots where class 5.1.1 or 5.1.2 substances are present O11 102, 103 Requirements to control adverse effects of intended combustion or explosion of class 5.1.1 or 5.1.2 substances, including requirements for protective clothing and equipment. Hazardous Substances (Classes 6, 8, and 9 Controls) Regulations 2001 T1 11-27 Limiting exposure to toxic substances No ADE or TEL values are set at this time. T2 29, 30 Controlling exposure in places of work WES values are set for peracetic acid and hydrogen peroxide. T3/E5 5, 6 Requirements for keeping records of Controls T3 and E5 are combined. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 28 of 36 Control Code4 Regulation5 Topic Variations use T4/E6 7 Requirements for equipment used to handle hazardous substances Controls T4 and E6 are combined. T5 8 Requirements for protective clothing and equipment T7 10 Restrictions on the carriage of toxic or corrosive substance on passenger service vehicles Controls F2, O2 and T7 are combined. E1 32-45 Limiting exposure to ecotoxic substances No EEL values are set at this time and the default EELs are deleted. E2 46-48 Restrictions on use within application area As no EELs have been set, no application rate is able to be set under this regulation. However, an application rate is set as an additional control under section 77A. E7 9 Approved handler requirements The following control is substituted for Regulation 9(1) of the Hazardous Substances (Classes 6, 8, and 9 Controls) Regulations 2001: (1). The substance must be under the personal control of an approved handler when the substance is (a) applied as a pesticide in a wide dispersive manner; or (b) used as a pesticide by a commercial contractor. Hazardous Substances (Identification) Regulations 2001 I1 6, 7, 32-35, 36 (1)-(7) General identification requirements Regulation 6 – Identification duties of suppliers Regulation 7 – Identification duties of persons in charge Regulations 32 and 33 – Accessibility of information Regulations 34, 35, 36(1)-(7) – Comprehensibility, Clarity and Durability of information I2 8 Priority identifiers for corrosive substances I3 9 Priority identifiers for ecotoxic Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 29 of 36 Control Code4 Regulation5 Topic Variations substances I5 11 Priority identifiers for flammable substances I7 13 Priority identifiers for oxidising substances I8 14 Priority identifiers for toxic substances I9 18 Secondary identifiers for all hazardous substances I10 19 Secondary identifiers for corrosive substances I11 20 Secondary identifiers for ecotoxic substances I13 22 Secondary identifiers for flammable substances I15 24 Secondary identifiers for oxidising substances I16 25 Secondary identifiers for toxic substances I17 26 Use of Generic Names I18 I19 27 29-31 Use of Concentration Ranges Alternative information in certain cases Regulation 29 – Substances in fixed bulk containers or bulk transport containers Regulation 30 – Substances in multiple packaging Regulation 31 – Alternative information when substances are imported I20 36(8) I21 37-39, 47-50 Durability of information for class 6.1 substances Documentation required in places of work Regulation 37 – Documentation duties of suppliers Regulation 38 – Documentation duties of persons in charge of places of work Regulation 39 – General content requirements for documentation Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 30 of 36 Control Code4 Regulation5 Topic Variations Regulation 47 – Information not included in approval Regulation 48 – Location and presentation requirements for documentation Regulation 49 – Documentation requirements for vehicles Regulation 50 – Documentation to be supplied on request I22 40 Specific documentation requirements for corrosive substances I23 41 Specific documentation requirements for ecotoxic substances I25 43 Specific documentation requirements for flammable substances I27 45 Specific documentation requirements for oxidising substances I28 46 Specific documentation requirements for toxic substances I29 51-52 Duties of persons in charge of places with respect to signage I30 53 Advertising corrosive and toxic substances Hazardous Substances (Packaging) Regulations 2001 P1 5, 6, 7 (1), 8 General packaging requirements Regulation 5 – Ability to retain contents Regulation 6 – Packaging markings Regulation 7(1) – Requirements when packing hazardous substance Regulation 8 – Compatibility P3 9 P11 17 P13 19 P14 20 P15 Regulation 9A and 9B – Large Packaging Packaging requirements for substances packed in limited quantities Packaging requirements for ethaneperoxoic acid, < 5% acetic acid and hydrogen peroxide Controls P11, P13, P14 and P15 are combined. 21 Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 31 of 36 Control Code4 PG2 Regulation5 Topic Schedule 2 The tests in Schedule 2 correlate to the packaging requirements of UN Packing Group II (UN PGII). PS4 Schedule 4 This schedule describes the minimum packaging requirements that must be complied with when a substance is packaged in limited quantities Variations Hazardous Substances (Disposal) Regulations 2001 D2 D3 D4 D5 D6 D7 D8 6 7 8 9 10 11, 12 13, 14 Disposal requirements for ethaneperoxoic acid, < 5% acetic acid and hydrogen peroxide Controls D2, D3, D4 and D5 are combined Disposal requirements for packages Disposal information requirements Disposal documentation requirements Hazardous Substances (Emergency Management) Regulations 2001 EM1 6, 7, 9-11 EM2 8(a) EM5 8(d) EM6 8(e) EM7 8(f) EM8 12-16, 18-20 EM9 17 EM10 EM11 21-24 25-34 EM12 35-41 Level 1 emergency management information: General requirements Information requirements for corrosive substances Information requirements for oxidising substances and organic peroxides Information requirements for toxic substances Information requirements for ecotoxic substances Level 2 emergency management documentation requirements Additional information requirements for flammable and oxidising substances and organic peroxides Fire extinguisher requirements Level 3 emergency management requirements – emergency response plans Level 3 emergency management requirements – secondary containment The following subclauses shall be added after subclause (3) of regulation 36: (4) For the purposes of this regulation, and regulations 37 to 40, where this substance is contained in pipework that is installed and operated so as to manage any loss of containment in the pipework it— (a) is not to be taken into account in determining Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 32 of 36 Control Code4 Regulation5 Topic Variations (5) EM13 42 whether a place is required to have a secondary containment system; and (b) is not required to be located in a secondary containment system. In this clause, pipework— (a) means piping that— (i) is connected to a stationary container; and (ii) is used to transfer a hazardous substance into or out of the stationary container; and (b) includes a process pipeline or a transfer line. Level 3 emergency management requirements – signage Hazardous Substances (Personnel Qualification) Regulations 2001 AH1 4-6 Approved Handler requirements See E7. Hazardous Substances (Tank Wagons and Transportable Containers) Regulations 2004 Regulations 4 to 43 where applicable The Hazardous Substances (Tank Wagons and Transportable Containers) Regulations 2004 prescribe a number of controls relating to tank wagons and transportable containers and must be complied with as relevant. Section 77 and 77A Additional Controls The controls relating to stationary container systems, secondary containment and unintended ignition of flammable substances, as set out in Schedules 8, 9 and 10 of the Hazardous Substances (Dangerous Goods and Scheduled Toxic Substances) Transfer Notice 2004 (Supplement to the New Zealand Gazette, 26 March 2004, No. 35, page 767), as amended, shall apply to this substance, notwithstanding clause 1(1) of Schedules 8 and 9 and clause 1 of Schedule 10. Addition of subclauses after subclause (3) of Regulation 36 of the Hazardous Substances (Emergency Management) Regulations 2001, refer control EM12. Ethaneperoxoic acid, < 5% acetic acid and hydrogen peroxide shall not be applied onto or into water. When used as a pesticide, the maximum application rate for Ethaneperoxoic acid, < 5% acetic acid and hydrogen peroxide shall be 8625 g hydrogen peroxide and 1725 g peracetic acid per ha with a maximum application frequency of 4 times per year and a minimum application interval of 7 days. When used as a pesticide, the method of application of ethaneperoxoic acid, < 5% acetic acid and hydrogen peroxide shall be restricted to ground-based methods only. Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 33 of 36 APPENDIX 5: GOVERNMENT DEPARTMENTS, CROWN ENTITIES AND INTERESTED PARTIES NOTIFIED Aakland Chemicals (1997) Limited AgBio Research Limited Agcarm Incorporated AgResearch Limited Agronica New Zealand Limited Ancare New Zealand Limited ARPPA BASF New Zealand Limited Bayer New Zealand Limited BOC Limited Bomac Laboratories Limited Caltex New Zealand Limited Central Hawkes Bay District Council Chancery Green Chemagro New Zealand Limited Chemsafety Limited Crown Public Health CSD Consultancy Ltd Donaghys Industries Limited Dow AgroSciences (New Zealand) Limited. DuPont (New Zealand) Limited Environment Southland Environment Waikato Evonik Industries Far North District Council Federated Farmers of New Zealand (Incorporated) Fish and Game Council of New Zealand Fish and Game Eastern Region Franklin District Council GE Free (Wairarapa) General Cable New Zealand Limited Greater Wellington - The Regional Council Green Party of Aotearoa New Zealand Horticulture and Food Research Institute (HortResearch) HQ Joint Forces New Zealand Human Rights Commission Hunt Agencies Limited IMCD New Zealand Limited Intervet Limited Jordens Nurseries Kaipara District Council Kawerau District Council Landcorp Farming Limited Lowndes Associates Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 34 of 36 Mackenzie District Council MAF Biosecurity New Zealand (MAFBNZ) Matamata-Piako District Council Merial New Zealand Limited Ministry of Research Science and Technology (MoRST) Muaupoko Co-operative Society Napier Health Centre - Public Health Unit National Aquarium of New Zealand National Institute of Water and Atmospheric Research Limited (NIWA) New Plymouth District Council New Zealand Chemical Industry Council Inc New Zealand Customs Service New Zealand Meatworkers Union New Zealand Press Association New Zealand Society of Gunsmiths Inc New Zealand Veterinary Association Inc New Zealand Bee Industry Group - Federated Farmers Ngati Kahungunu Iwi Incorporated Northern Chemical Workers Union Northland Health Northland Regional Council Nufarm New Zealand Limited Nursery and Garden Industry Association of New Zealand Inc Otago District Health Board Pacific Growers Supplies Limited Pesticide Action Network Aotearoa New Zealand Pfizer New Zealand Limited PharmVet Solutions Physicians and Scientists for Global Responsibility (PSGR) Rangitikei District Council Reckitt Benckiser Royal Forest and Bird Protection Society of New Zealand Inc. Rural and Associated Contractors Federation of New Zealand South Taranaki District Council Spraywatchers Group Sustainability Council of New Zealand Syngenta Crop Protection Limited Tairawhiti District Health Taranaki Regional Council Tasman District Council Te Pataka Matauranga Charitable Trust Technical Strategy Group Limited Television New Zealand Thames Coromandel District Council The Green Party of Aotearoa New Zealand Inc Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 35 of 36 The National Beekeepers Association of New Zealand TMP Consultancy University of Auckland Veg-Gro Supplies Limited Venco Ltd ViaLactia Biosciences (New Zealand) Limited Virbac Laboratories New Zealand Limited Yates Australia Zelam Limited 10 private individuals Consideration Paper – HRE08001 Modified Reassessment of Ethaneperoxoic Acid, <5% Acetic Acid and Hydrogen Peroxide Page 36 of 36