My Research about the silicon photonics

advertisement

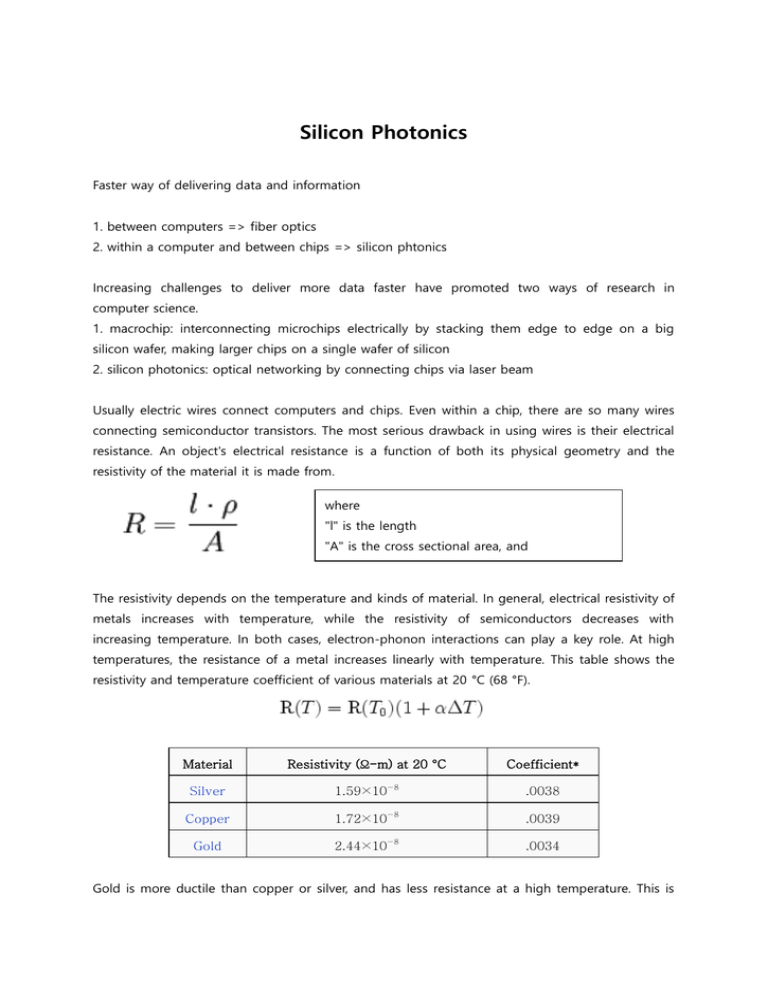

Silicon Photonics Faster way of delivering data and information 1. between computers => fiber optics 2. within a computer and between chips => silicon phtonics Increasing challenges to deliver more data faster have promoted two ways of research in computer science. 1. macrochip: interconnecting microchips electrically by stacking them edge to edge on a big silicon wafer, making larger chips on a single wafer of silicon 2. silicon photonics: optical networking by connecting chips via laser beam Usually electric wires connect computers and chips. Even within a chip, there are so many wires connecting semiconductor transistors. The most serious drawback in using wires is their electrical resistance. An object's electrical resistance is a function of both its physical geometry and the resistivity of the material it is made from. where "l" is the length "A" is the cross sectional area, and "ρ" is the resistivity of the material The resistivity depends on the temperature and kinds of material. In general, electrical resistivity of metals increases with temperature, while the resistivity of semiconductors decreases with increasing temperature. In both cases, electron-phonon interactions can play a key role. At high temperatures, the resistance of a metal increases linearly with temperature. This table shows the resistivity and temperature coefficient of various materials at 20 °C (68 °F). Material Resistivity (Ω-m) at 20 °C Coefficient* Silver 1.59×10−8 .0038 Copper 1.72×10−8 .0039 Gold 2.44×10−8 .0034 Gold is more ductile than copper or silver, and has less resistance at a high temperature. This is why gold is used as micro wires in a semiconductor chip. However, in a motherboard which has a lot of chips connected with each other, copper wires are used. These metal wires generate additional currents and heats leading to less energy efficient operating. It also causes bottlenecks because electrical current is slower than light speed. Photonics is the technology of signal processing, transmission and detection where the signal is carried by photons (light) and it is already heavily used in photonic devices such as lasers, waveguides or optical fibers. Optical technology has always suffered from its reputation for being an expensive solution, due to its use of exotic materials and expensive manufacturing processes. This prompted research into using more common materials, such as silicon, for the fabrication of photonic components, hence the name silicon photonics. Although fiber-optic communication is a well-established technology for information transmission, the challenge for silicon photonics is to manufacture low-cost information processing components. Rather than building an entirely new industrial infrastructure from scratch, the goal here is to develop silicon photonic devices manufactured using standard CMOS techniques. A recent review paper takes a look at the state of silicon photonics and identifies the challenges that remain on the path to commercialization. The ultimate goal of this project is to develop a technology for on-chip integration of ultracompact nanophotonic circuits for manipulating the light signals, similar to the way electrical signals are manipulated in computer chips. [Futuristic silicon chip with monolithically integrated photonic and electronic circuits] This hypothetic chip performs all-optical routing of multiple N optical channels each supporting 10Gbps data stream. N channels are first demultiplexed in WDM (wavelength-division multiplexing) photonic circuit, then rearranged and switched in optical cross-connect OXC module, and multiplexed back into another fiber with new headers in WDM multiplexer. Data packets are buffered in optical delay line if necessary. Channels are monitored with integrated Ge photodetector PD. CMOS logical circuits (VLSI) monitor the performance. Electrical pads are connecting the optoelectronic chip to other chips on a board via electrical signals. (Image: IBM) In order to "siliconize" photonics, there are six main areas or building blocks for investigation. These include generating the light, selectively guiding and transporting it within the silicon, encoding light, detecting light, packaging the devices and finally, intelligently controlling all of these photonic functions. Intel is working to address these areas, and this research has produced a few recent success stories, including the first continuous-wave silicon laser and the first gigabit speed silicon modulator. low-cost all-silicon Raman laser First GHz Silicon Optical Modulator Optical modulators are used to encode a high-quality data signal onto an optical beam, effectively by turning the beam on and off rapidly to create ones and zeros. Before the year 2004, no one had built an optical modulator from silicon that was faster than about 20 MHz. In 2005, Intel researchers further demonstrated that this silicon modulator is capable of transmitting data up to 10 gigabits per second (Gbps). Silicon photonics: (1) The thin lines on the surface of this chip are waveguides, carved into channels silicon that direct light. (2) Five indium-phosphidebased lasers mounted to a die. (3) Luxtera researchers modified a standard piece of semiconductor test equipment so that it can test optical as well as electrical functions. (4) This device couples fiber to Luxtera’s siliconbased chip. Credit: Luxtera