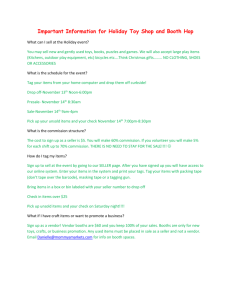

Click here to view the slide show

Measures and Trust in SCM

Eli Schragenheim

Elyakim@netvision.net.il

The IT Vision for Supply Chains

In the future the main competition will be between supply chains

Every supply chain has to react very fast to the changing trends in the taste of consumers

The stumbling block to fast reaction throughout the supply chain is lack of information

Current IT technology is capable of very fast

B2B communication that would provide full collaboration throughout the supply chain

A Hole in the IT Vision

Suppose that company S identifies a rising demand for product P produced by Vendor V. All the relevant information is communicated to V in no time

– Would Vendor V immediately start to produce according to the forecast by company S?

Take into account that V is paid so-and-so days after S places an order and gets the delivery

Does V trust S? Who would suffer if the optimistic forecast does not materialize?

Is S truly interested in communicating all relevant information to V?

An Inherent Problem in SC

The idea behind SCM is that by acting as one big system better results for all the participants can be achieved

– Can it work when some links have not implemented the systemic rules within their own organizations?

Every organization that is part of a supply chain looks for its own benefit

– Hence, every link must clearly profit from acting within the supply chain rules

– This kind of business relationship is frequently referred to as “collaboration”

– Can it work without a win-win culture?

– And we need to establish trust between all the links

Business Rules in SCM

The regular business rule: the vendor receives a concrete order, and is paid some time after delivery

– Being exposed to updated information won’t impact the vendor’s decisions

– The vendor has no say regarding the size of the order

If it is too small – then sales will be lost

If it is too high, it will take very long time until the next order is received

It is not clear the vendor can profit from a faster response

– On one hand the next link might be able to sell more

– On the other hand the next link might order less

Demand for

P10 goes up

Seller:

How much to order?

Can you deliver 300 P10 in a week?

I need it faster

All right, two weeks, and then make it 500 units

It'll take

3 weeks

The best I can do is two weeks

Producer:

How fast to respond?

Business Rules in SCM

Vendor Managed Inventory

– The next link draws from the vendor’s inventory when the need arises and this triggers payment to the vendor

– All the risk is now placed on the vendor

Now the vendor has a lot to gain from a fast response

– Financial benefits to the vendor would occur, if and only if, sales would go up due to the new rule

This is possible if it enables the seller to spot new opportunities and then rely on a secure and fast response

– In the former scheme the seller would refrain from holding inventory for such opportunities

And less sales are lost due to shortages

The TOC Visionary Business Rules

The objective:

– Allow the seller to grab any opportunity that is beneficial to all the links in the chain

– Motivate all the links to respond quickly to any market trend

– Institute a win-win culture over the entire chain

– Let those who have the best knowledge and intuition make the decisions

– Each link gets more

The TOC Visionary Business Rules

The TOC business rule:

– Each producer in the link manages his finished goods inventory at the next link

– Payment is made immediately following each daily sale by the seller

– Every producer gets:

The truly variable costs (TVC) invested by the producer

A percentage of the throughput (T)

– Throughput is the revenues minus the truly variable costs

– It is in everybody’s interest not to cannibalize any sales and not to ignore any optional sale

Supporting the TOC Scheme

Every link within the chain should manage its operations based on replenishment to the buffers

– The inventory at the next link is a buffer

– Every producer might maintain its own finished goods buffer when the same product/part goes to different supply chains

Using buffer management as a sensitive tool to identify changes in the market demand

Information on each sale should flow immediately to every link in the chain

But, there is a need to validate that every link in the chain is doing what it should do to allow more business to come in

How to Maintain Trust between

Different Organizations?

The win-win agreement is not enough to ensure high performance

We need measurements of the performance of each link to establish an overall control whereby the actions truly support the global chain

– The downstream links need to ensure fast response to any market opportunity

– The upstream links need to validate that sales are generated from what is already in the system

Note that maintaining trust is needed also for the other business rules

How should a seller measure the performance of the vendor?

Criteria

– Every delay in measured, not just being late but also by how many days

– The financial value of the sale should be measured as well

Throughput-Dollar-Days (TDD)

– Every day a delay is noted the full T value of the order is added to a counter of TDD

– When the order is late by 5 days, its full T value is added to the counter 5 times

How should a seller measure the performance of the vendor?

A common problem at the seller’s site

– Orders that cannot be fulfilled may not have been registered, even though the specific sale has been lost

– Hence, the full damage caused by the unavailability of products cannot be directly measured

How should a seller measure the performance of the vendor?

The TDD measurement in this case could be directed to the emergency level of the parts

– The emergency level (zone 1 / red-line) is defined in the buffer management methodology

– It is usually a certain percentage of the replenishment buffer

– The emergency zone represents a very high probability of losing sales

– Hence, when the on-hand stock is below the emergency zone – the TDD counter ticks

An example: Product P10

Seller

Inventory ready for

T per unit = $60 immediate sale

Fast replenishment

Replenishment level = 100 un.

Emergency level = 30 un.

Producer

On 4/15/2002:

On hand stock = 17 un.

Additional TDD due to P10: (30-17)*60 = 780 dollar-days

On 4/16/2002 the on hand stock went down to 5 units

Additional TDD = (30-5)*60 = 1500 dollar days

Total TDD due to P10 = 1500 + 780 = 2280 dollar-days

The TDD as a measure of the performance of a vendor to a seller

The vendor is responsible for full availability of his products at the seller’s site

The replenishment and emergency zone levels are agreed between the seller and the vendor

Whenever the on-hand stock is below the emergency level the TDD counter ticks

– The full throughput value of the parts that are missing is added to the periodical TDD measurement

– When no stock is available at the seller, the full T value of the whole emergency level as added every day

– This measure rises VERY fast when response time drops

– The measure institutes the right priorities given both the financial aspects and the duration of the delay

The TDD measurement for a vendor of a producer

The differences between measuring the performance of a vendor to a seller and to a producer

–

The producer knows exactly when lack of materials causes a delay in the internal operations

– The financial damage of missing a part is more problematic to measure

The part might participate in a variety of end-items sold by the supply chain

Hence, for every part the vendor is responsible for a

“typical end-product T” should be defined

We still assumes that delay in the producer’s operation might cause missing a final sale, even though this is much less straightforward

The TDD as a measure of the performance of a vendor to another producer

The vendor is responsible for full availability of his products as raw materials at the producer’s site

The replenishment and emergency zone levels are agreed between the producer and the vendor

Whenever the producer needs to release materials to the floor and a specific part is missing the TDD counter ticks

– The exact amount of units missing multiplied by the typical T for the end-products is added every day to the periodical TDD

Whenever C needs materials and they are not found in

Inventory B, the TDD counter in increased by the T of the end items

Link C measures B’s performance according to the periodic TDD

Link C

Inventory B

Link B

Inventory A

Link A

Measuring the performance of the seller

Every link in the chain that is not the seller likes to judge the performance of the seller

– This is true even for the traditional business rules

– The main focus is how fast products that are stocked at the seller’s site are being sold

And what products are NOT sold!

Every producer that is judged according to TDD has to invest capacity and materials in an effort to maintain the TDD and gain from the supply chain sales

– Hence, there is a need to measure the investment

The faster the seller succeeds to sell the more effective is the investment

Seller

Inventory ready for immediate sale

Producer

What products do not sell well?

How much money is stuck in slow products?

The finished goods inventory represents an investment on the producer's part

Inventory-Dollar-Days measuring the flow

Every area that contains inventory can be measured according to:

– The value of the item – only the raw material purchasing costs are considered

– The number of days each item remains in the area

Every item in the measured area carries inventory dollar days equal to its value in dollars multiplied by the number of days it remains in the area

The IDD is a snapshot: how much money is stuck in the area and for how long

Basic calculation of the IDD for an area

10 items, each worth

$50 go in

A measured area where inventory items spend some time

The 10 items go out after

14 days

On the first day the IDD for these items is 500 DD

On day 14 the IDD for these items is

7000 DD

On day 15 the IDD for these items is

0 DD

Using the IDD measurement

Each producer should measure the following areas:

– Raw materials from vendors that are not managing their materials

– WIP

– Every finished goods area that is controlled by the producer

Under the TOC supply chain vision the area that truly measures the performance of all the downstream link is:

– From the completion area in the shop until the supply chain sells it

TDD measurement

Link C

Inventory B

TDD measurement

Link B

Inventory A

Link A

Every day link A adds to the IDD measure, the value of all its inventory in the supply chain

IDD and Inventory Turns

Inventory turns is the current common measurement of the effectiveness of inventory in the system

– It measures the average of how much inventory waits in a certain area

– The dollar value of the inventory is specified separately

– Being an average, it misses pointing to the problematical area, and it does not give a clue regarding the variability

– The combined effect of time (delays) and money is given only at a very global level

Summary

The TOC vision for supply chains provides a new business scheme for real collaboration between the links

All the current business rules for supply chains should maintain trust among all parties

Trust needs to be supported by a measurement system that motivates all the parties to do what is good for the chain as a whole

The measurements need to contain both time and money

Summary

Throughput-dollar-days (TDD) measures the performance of the vendors by accumulating the full dollar value of every late order and the length of time it was delayed

Inventory-dollar-days (IDD) measures the flow through the supply chain by measuring how much inventory-money is being held at each area, thus blocking the flow

IDD should be used, among other uses, to check how fast products are being sold

Summary

Both the TDD and IDD measurements have uses that stretch beyond measuring the performance of the links in the supply chain

The TDD is an operational performance measurement of the damage caused by failing to meet the market requirements

The IDD is a measure of effectiveness of the operational policies to achieve as low TDD as possible