Battery-Supercapacitor Hybrid Energy Storage System

advertisement

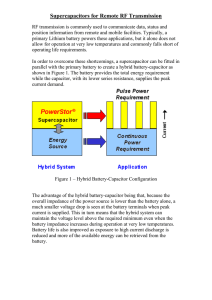

Design Team 10 ECE 480 FS08 Progress Report 2 Battery-Supercapacitor Hybrid Energy Storage System Since the last progress report, we have been ordering the parts needed for the project and thinking about different designs. There were four proposed designs for delivering power to a pulsating load: 1) Using just supercapacitors 2) Using just batteries 3) A hybrid system using both batteries and supercapacitors in parallel. 4) A hybrid system using both batteries and supercapacitors with active circuit components between the two. The first system would require too many supercapacitors. The second system is the current technology in use. The third system would reduce battery size, but would need more than three supercapacitor modules, which cost over $2200 apiece. It also requires the battery & supercapacitor module to have the same voltage level, limiting its effectiveness. The fourth system has the most potential because it utilizes modern semiconductor technology to address the problems inherent in the system three design. Battery: The team purchased 14 lithium polymer (Li-PO) battery cells, each rated at 3.7 volts and 21 Amp hours. These cells will be connected in series to yield a total of 51.8V. We chose to use 14 cells because of the difficulty associated with obtaining a 13 cell, 48.1V PCM. Since we are building the fourth system, active components will compensate for the voltage difference between the 48.6V supercapacitor and the 51.8V (nominal) battery. The PCM supplier was out of stock of the battery fuel gauges used with the particular PCM we selected. We are currently researching other means to determine and display the energy level in real-time. Supercapacitor: The team purchased a 165F super capacitor module from Maxwell Technologies. Their 83F module would have been capable of meeting our parameters however, the supplier did not have this module in stock and estimated a six week wait. Obviously this was not compatible with the semester time frame and our design schedule. Instead, we purchased the 165F module which cost approximately $600 more than the 83F module. Our prototype hybrid system will utilize high current, solid state relays to disconnect certain elements from the circuit, such as the battery, at opportune times during the operating cycle, corresponding with the power demand of the load. This will allow the system to take advantage of the high power density of the supercapacitors and shield the battery form the damaging effects of short, instantaneous bursts of increased load demand. Once the load demand levels off and returns to normal, the battery will be reconnected to the circuit, recharging the supercapacitors at a slower rate than they were discharged. This takes advantage of the batteries high energy density and prepares the system for the next spike in load demand. Because this system isolates the battery from the supercapacitor module and then reintroduces it, the supercapacitors charge, partially discharge and then recharge making the system require only one Supercapacitor module. Given the same discharge time period and load, the 165F supercapacitor module will discharge a lower percentage of its total charge compared to the 83F module. This means that the voltage drop experienced as the supercapacitors discharge will be reduced, potentially increasing system performance and allowing it to exceed the project’s minimum parameters. Design Team 10 ECE 480 FS08 Progress Report 2 Load: The team has ordered the components necessary to build a basic, programmable, pulsating load of 2.5Ω. Using a Millennium 3 programmable relay controller, high current, conventional relays, and two 1kW rated 5Ω resistors connected in parallel, the team will construct the basic load required. Once the entire system is assembled, it will be tested on this rudimentary load. Subsequent improvements will be made, such as adding more resistors and relays and having some element of the load which can be visually verified. Budget: We have currently used just under half of our $10,000 budget. Part # Model Prototype Ultracapacitors ESHSR-0010C0002R7 BMOD0165 Item/Info NessCap Co Ltd Maxwell Technologies BMOD016548.6V PCMs Model PCM-B03S10-188 Prototype PCM-L14S40-232 PCM,Equilibrium Function, 3 cell LiIon/PO PCM with Equilibrium function for 14 LiIon Cells Batteries Prototype Model F ESR mOhm 15 $3.25 2.70 10.00 35.00 1 $2,240.00 48.10 165.00 7.10 Sub Total: $2,288.68 QTY $ V A Limit 1 $13.32 11.10 10.00 1 $99.95 51.80 40.00 Sub Total: $113.27 QTY $ V A/H ESR mOhm 14.00 $94.00 3.70 42.00 PL-6045135U Hi-Power Polymer Li-Ion Cell 3 $17.50 3.70 3.00 Sub Total: $1,368.50 QTY $ V Connection 1 $119.85 3.70 USB Sub Total: $119.85 QTY $ Ω W V 2 $149.56 5.00 1000.00 70.711 Sub Total: $299.12 QTY $ V AWG A CBA-II Computerized Battery Analyzer TA1K0PH5R00KE Ohmite, Thick Film PCB-3GS-1 Fuel Gauge, PCB of 11.1v Battery Pack 1 $7.95 11.10 Prototype CN-SA2 Anderson Connector 3 $9.99 8" Prototype D1D40 Solid State Relay (SSR) 4 $65.22 100.00 40.00 Prototype G8P-1A2T-F-DC24 10 $3.36 250.00 30.00 Prototype 88970084 Relay, PWR SPST, 24V Coil START KIT LOGIC CNTRL XD26 24VDC 1 $277.00 24.00 Sub Total: $609.43 TOTAL: 12.00 OD 22 Oct 11 Nov 22 Oct 5 Nov 14 Miscellaneous Model V Polymer Li-Ion Cell: (2C) rate Resistors Prototype $ 1055275 UL listed Battery Analyzer Both QTY 40.00 5 Nov 22 Oct 22 Oct 14 Nov 22 Oct 5 Nov 14 Nov 14 Nov 14 Nov $4,798.85 Shipping: $45.90 Grand Total $4,844.75 * Shipping for items ordered November 11th or later is not included in this total. Design Team 10 ECE 480 FS08 Progress Report 2 Gant Chart