Poster23.ppt

advertisement

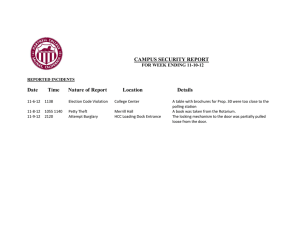

Problem Definition Sponsor Background • Includes the Mercedes-Benz, Chrysler, Dodge, and Jeep brands. • Formed during merger of Daimler-Benz and Chrysler Corporation in 1998 • American operations are headquartered in Auburn Hills, MI • Over 360,200 employees and $200.4 billion in revenue as of 2006 MSU Team Joe Affonso Jimmy Chen Nick Harrington Mike Nicley Industrial Advisor George Konstantakopoulos Faculty Advisor Dr. John Foss Electrical Consultant Shannon Nicley Final Design • The Infinite Position Door Check system will hold a swing-type passenger vehicle door in any opened position the operator desires • This project will be initially modeled on a production door from a Chrysler 300, but should be scalable to any application within DaimlerChrysler • The final prototype should represent a production-ready, inexpensive, and adjustable design • It will open and close identically to current production doors, but without pre-set detents • When stopped in any position, the door will remain in position until its holding force is overcome by the user, at which time the door will swing freely Final Design Assembly, SolidWorks Model Design Specifications Economic Analysis • Hold door stationary at any user defined position • Product will initially be marketed as a luxury option • Perform similarly to current door check systems •Prototype component and material costs are $53 per unit when commercial retail pricing is used, not including labor or assembly • Designed for lowest cost possible • Dependable and reliable • Safe during use, handling, and installation • Add luxury to the users experience with the automobile • Eliminate door bumps which can occur when a door “falls into” a pre-set detent Initial Design Concepts Prototype, Fully Mounted In-Door Design Recommendation • The final design is electronically controlled • During door movement, a position sensor sends a signal to a microcontroller • The control system then disengages a holding frictional piece • When the door is stopped and held by the user, the signal from the position sensor turns off • The control system then engages an electric motor which is attached to a force multiplier Centrifugal Clutch System Electronically Actuated System • The rotational motion is converted to lateral motion by a scissor jack type force multiplier • Shaft rotation causes one end of the force multiplication truss to push a steel semi-cylindrical friction part against a steel cylinder attached to the door hinge Viscous Piston Cylinder Prototype Hinge Portion, with Position Sensor • When the user pulls on the door and overcomes this holding force, the position sensor starts to move, signaling the motor to release the holding force • Market polling indicated consumer willingness to pay an average of $200 per door for this feature • Total production cost is $34 per unit • The frame, friction material, and pivot cylinder could be mass-produced for a total cost of $6 per unit • Bulk purchasing of the motor, motor attachment, and electronic components would yield a total cost of $25 per unit • Assembly and installation costs total $3 per unit Conclusions • This design represents a feasible solution to the problems posed in the creation of an Infinite Position Door Check system • Prototype is functional, despite power losses which result in a smaller-than-desired holding force • Full-function, production-ready prototype can be achieved with minor design changes and increased component precision