concurrentengineering[1]

advertisement

![concurrentengineering[1]](http://s2.studylib.net/store/data/015258210_1-27bd91d9c3dd21c406717035bea3507f-768x994.png)

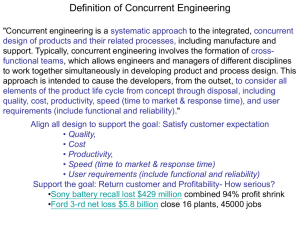

Concurrent Engineering Developed by: Robert Wyant Penn State University What Will Be Covered Concurrent Engineering Defined Brainstorming Nuts and Bolts How It Works Example of Concurrent Engineering An Exercise Concurrent Engineering Defined 1st Definition “The simultaneous performance of product design and process design. Typically, concurrent engineering involves the formation of crossfunctional teams. This allows engineers and managers of different disciplines to work together simultaneously in developing product and process design.” Foster, S. Thomas. Managing Quality: An Integrative Approach. Upper Saddle River New Jersey: Prentice Hall, 2001. Concurrent Engineering Defined 2nd Definition “Concurrent engineering methodologies permit the separate tasks of the product development process to be carried out simultaneously rather than sequentially. Product design, testing, manufacturing and process planning through logistics, for example, are done side-by-side and interactively. Potential problems in fabrication, assembly, support and quality are identified and resolved early in the design process.” Izuchukwu, John. “Architecture and Process :The Role of Integrated Systems in Concurrent Engineering.” Industrial Management Mar/Apr 1992: p. 19-23. Brainstorming Brainstorm some ideas about Concurrent Engineering How can this tool be used in your organization? Nuts and Bolts Basic Tenets of Concurrent Engineering -Doing things simultaneously -Focusing on the Process -Converting hierarchical organizations into teams Nuts and Bolts Basic Goals of Concurrent Engineering -Dramatic improvements in time to market and costs -Improvements to product quality and performance -Do more with less Nuts and Bolts Concurrent Engineering = Teamwork -The more communication exists, the better the product. Balances Needs -Customer, Supplier, Engineers, Marketing, and Manufacturing needs. Nuts and Bolts Management -Good mgmt is vitally important -Encourage communication -Strong mgmt support How it Works 3 Main Areas to Concurrent Engineering 1) People 2) Process 3) Technology How It Works Area 1: People -Formation of teams -Training How It Works Area 2: Process -Changes in your processes -Be open to change How It Works Area 3: Technology -CAD/CAM -Software. Hardware, and Networking How It Works Basic Summary -Most important aspect is People -Process and Technology: Don’t be afraid of change Real World Example Titan Linkabit -Develops circuit boards - CAE technical manager, Chip Ciradot Real World Example Titan Linkabit -Old CAD system: 21 weeks to develop 8layer circuit board. -Implemented new CAE tools and CE -New circuit board: 12 weeks to develop, 10 layers, twice the functionality of the 8 layer. A Short Exercise Come up with some ideas as to how implementing Concurrent Engineering could be useful in your organization? How will you form teams? Open communication? Change processes? Implement technology? Summary Concurrent Engineering: Simultaneous development of product and process. Most important aspect is communication and formation of teams Management support is vitally important Don’t be afraid to change current processes and technologies Bibliography Foster, S. Thomas. Managing Quality: An Integrative Approach. Upper Saddle River New Jersey: Prentice Hall, 2001. Izuchukwu, John. “Architecture and Process :The Role of Integrated Systems in Concurrent Engineering.” Industrial Management Mar/Apr 1992: p. 19-23. Litsikas, Mary. “Break Old Boundaries with Concurrent Engineering.” Quality Apr 1997: p. 54-56. Mills, Robert. “Concurrent engineering: Alive and well.” CAE. Aug 1993: p. 41-44