AIAG

advertisement

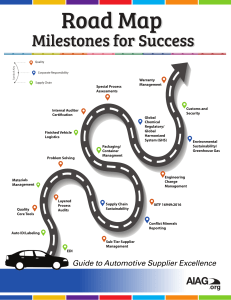

Automotive Industry Action Group (AIAG) John Romankiw 12/3/2006 1 Agenda 1. AIAG Defined 2. Brainstorming Exercise 3. Nuts and Bolts 4. How it works 5. Testimonies 6. Exercise 12/3/2006 2 AIAG’s Vision AIAG is the catalyst for the global automotive industry’s efforts to establish a seamless, efficient and responsible supply chain 12/3/2006 3 Brainstorming Exercise • Think of three problem areas in your supply chain • Write these problems down 12/3/2006 4 Nuts and Bolts What can AIAG do for your company? • Automatic Identification and RFID • Collaborative Engineering and product Development • E-commerce • Health Focus 12/3/2006 5 Nuts and Bolts (continued) • Occupational Health and Safety • Quality • Emerging Markets 12/3/2006 6 Automatic Identification and RFID • Standardized rules for are codes, 2-D symbols, and RFID • Warranty Reduction • Anti-counterfeit Parts • RFID for Wheels and tires 12/3/2006 7 Collaborative Engineering & Product Development • Global Metrology Quality Measurement Data Standard Data exchange between gages and tools Production time and money savings • Dimensional Mark Up Language Interoperability Reduction of cycle time and manufacturing costs 12/3/2006 8 E-commerce • Inventory Visibility and Interoperability Project (IV&I) Reduction on Lead Time in Supply Chain Auto Industry savings of $255 million • Joint Automotive Data Model 12/3/2006 9 Health Focus • Reduce waste in the supply chain • Health Awareness • Disease prevention and management 12/3/2006 10 Occupational Health & Safety • Reduce Work Place Injury • HAZMAT • Vehicle Labels • Small Lot Delivery 12/3/2006 11 Quality • Production Part Approval Process (PPAP) • Problem Solving Guidelines • Statistical Process Control 12/3/2006 12 Emerging Markets • B2B Survey in China • Global Working Conditions • Cooperation Agreement 12/3/2006 13 How It Works How Can You Become a Member of AIAG? • Coorprate Membership • Based on Annual Revenue • Associate Membership • Flat Fee 12/3/2006 14 Testimonials "AIAG helps us to understand where technology is moving, even in something as simple as labeling. Because we were involved in AIAG, Freedom saw all the new Ford labeling requirements long before they were implemented publicly. Obviously, this knowledge helped us with our own customers, because we made sure we were Ford-compliant before they knew what was expected of them." Rick Scorey, President Freedom Technologies 12/3/2006 15 Testimonials "AIAG gives me the opportunity to improve the industry instead of just sitting back and complaining about things that are not going right. The most rewarding part of my AIAG experience was the recent success of our IV&I proof-of-concept effort. We have finally found a way that will allow us to electronically connect the entire supply chain that will be affordable and effective for all involved. To know that adoption of the technology tested in this project will allow us to communicate inventory information much more quickly so that the supply chain won't have to carry excess inventory, especially at the lower tiers - that has to be the highlight for me." Terry Onica, QAD 12/3/2006 16 Exercise 1. Draw a brief relationship diagram for your supply chain. 2. Label all the areas that you are having problems with communication, quality, standardization of information, or any other thing that you can think of. 3. In what ways can AIAG help your organization smooth out problems in your supply chain? 12/3/2006 17 Summary • Streamline the industries processes and business practices • Speed and improve industry supply chain • Improve quality • Foster relations among organizations in the auto industry 12/3/2006 18 Readings list • Automotive Action Group • FreeQuality http://www.freequality.org • OpenStandards • RFIDJournal 12/3/2006 http://www.aiag.org/Index.cfm http://www.openstandards.net http://www.rfidjournal.com/article/articleview/2778/ 19