Effects of Aluminum and N,N-dimethylformamide additives on Tb 3+ fluorescence in Sol-Gel glasses

advertisement

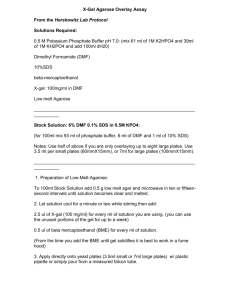

Dwight Swift and Dan Boye Physics Dept., Davidson College The Sol-Gel Process Synthesis at low temperatures Less exotic equipment required Accurate control of dopant concentrations Higher fluorescent ion capacity Control of other factors pH, distribution Many shapes possible Fibers, thin films Sample Preparation Ingredients added as per recipe TMOS + DMF with catalytic acid Stages Gelation – Long Si-O-Si chains condense into a gel Aging – Chains cross-link and liquid precipitates out Drying – Temperature is raised to remove excess liquid Annealing – High temperatures (900C-1100C) densify glass Fluorescence Quenching Energy transfer to the silica matrix Degree varies with host material Energy transfer to hydroxyl groups Water from re-hydration Cross-relaxation between Rare Earth (RE) ions Clustering on pore surfaces All optically non-radiative decay mechanisms Energy Levels of 30 28 Emission Spectrum (λexc=240nm) 5D 3 26 5D 7F 3 J 22 Fluorescence (a.u.) 620nm 590nm 490nm 542nm 437nm 460nm 414nm 18 14 12 10 8 6 4 2 0 5D 7F 4 J 5D 4 20 378nm Energy (1000cm-1) 24 16 3+ Tb 542nm 437nm 7F 0 1 2 3 4 5 7F 6 Wavelength (nm) Sample Spectroscopy Nd:YAG pumped dye laser with summing crystals Excitation wavelengths Pulsed vs. Continuous excitation Allows a look at decay profile 437 /542 peak amplitude ratio Focus on quenching mechanisms Calibrate across samples Experimental Setup Detector System Laser System KD*P WEX Pulsed Nd:YAG BS 532nm Oscilloscope Pin-hole Filter PMT DCM dye laser 586nm sol-gel glass monolith 1064nm 378nm Filter Spectrometer Decay Profiles Raw Data Smoothed with Savitzky-Golay Algorithm 542nm ~2mS 437nm ~400μS Adding a DCCA Drying Control Chemical Additive (DCCA) N,N-dimethylformamide (DMF) Replaces H2O in the drying process Stronger bond Lower vapor pressure, capillary forces Reduced stress in drying Pore size uniformity Average pore size increase Densification to resist rehydration Rehydration without DMF 0.6 Relative 5D3 to 5D4 ratio 0.5 0.4 0.3 0.2 0.1 0 0 5 Elapsed time (hours) 10 Rehydration with DMF DMF-sol gel glass. 0.02%Tb, 1050C and 6h dwell. 0.45 5 D /5 D 3 4 Intensity Ratio 0.4 0.35 0.3 0.25 0.2 0.15 0.1 0.05 0 0 2 4 6 8 Elapsed Time [hours] 5 D /5 D 3 4 Intensity Ratio = constant= 0.409±0.001 10 12 0% Aluminum 0.08 0.07 437/542 Ratio 0.06 0.05 0.04 2.0% Tb 0.02% Tb 0.03 0.02 0.01 0 900 950 1000 1050 1100 Annealing Temperature (C) 1150 Aluminum Co-Doping Found to enhance fluorescence Somewhat ambiguous Brings in non-bridging Oxygens NBO’s sought out by Tb Originally thought to distribute Tb in matrix Effect of adding Al saturates at Al:RE ratios of 10:1 or greater (without DCCA) 0.02% Terbium 3 437/542 Ratio 2.5 2 2% Al 1.5 1% Al 0% Al 1 0.5 0 900 950 1000 1050 Annealing Temperature (C) 1100 1150 0%Al 3 437/542 Ratio 2.5 2 0.02%Tb 0.05%Tb 1.5 0.2%Tb 0.5%Tb 1 1.0%Tb 2.0%Tb 0.5 0 850 900 950 1000 1050 1100 Annealing Temperature (C) 1150 1200 1%Al 3 437/542 Ratio 2.5 2 0.02%Tb 0.05%Tb 1.5 0.2%Tb 0.5%Tb 1 1.0%Tb 2.0%Tb 0.5 0 850 900 950 1000 1050 1100 Annealing Temperature (C) 1150 1200 2%Al 3 437/542 Ratio 2.5 2 0.02%Tb 0.05%Tb 1.5 0.2%Tb 0.5%Tb 1 1.0%Tb 2.0%Tb 0.5 0 850 900 950 1000 1050 1100 Annealing Temperature (C) 1150 1200 Summary DCCAs can help control quenching due to rehydration Addition of aluminum increases overall brightness Aluminum reduces cross relaxation Past work has shown that cross relaxation is minimized for an Al:RE ratio of 10: 1 or greater With DMF, the 10: 1 ratio threshold appears to decrease DMF binds more strongly than water to Tb Further study of this effect is needed Future Work Look at Al:RE ratio reduction with DMF DMF Aluminum interaction Fluorescence with respect to DMF content Improve recipe for consistency Minimize sample cracking Questions?