01-10-2011 2328-71914 Syllabus.doc

advertisement

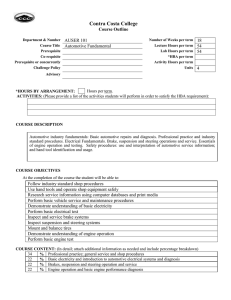

Course Syllabus AUMT 2328 – Automotive Service AUTOMOTIVE TECHNOLOGY TRAINING CENTER Houston Community College System NE Mr. ALEXANDER CRN: 71914 Semester / spring 2011 Date January 10, 2011 to March 3, 2011 8 Weeks (32 Day) Time of 7:00 PM – 10:00 PM Class Meets Room Number #209 Monday through Thursday OFFICE HOURS: 2:30 pm – 3:30 pm Office Room Number #210C Tel. 713- 718-8118 or 713-718-8100 Revised: January 7, 2011 1 Please feel free to contact me concerning any problems that you are experiencing in this course. You do not need to wait until you have received a poor grade before asking for my assistance. Your performance in my class is very important to me. I am available to hear your concerns and just to discuss course topics. Feel free to come by my office anytime during these hours. COURSE DESCRIPTIONPREREQUISITES; The introductory automotive class requires certain basic academic skills. These skills and the remedial classes needed to attain those skills are: Reading -- 5th to 7th grade minimum – remedial -- GUST 0339 Math -- Basic Math – remedial – MATH 0308 English -- Sentences and paragraphs remedial –ENGL 0300 or 0349 REQUIRED TEXTBOOK: Modern Automotive Technology Manual: 2008 Modern Automotive Technology Handbook: 2008 Author: James E. Duffy The textbook can be purchased at the campus bookstore, Northline Mall Camper, Northeast College. TIME AND DAYS OF THE COURSE; Classes are held Monday thorough Thursday from 7:30 pm to 10:00 pm Grading System: FINAL GRADE AVERAGE FORMULA: will be on the Friday of the 8th week of this course 25% Final Exam 20% Weekly Test 15% Daily Quiz 15% Shop/Lab 10% Daily Participation 5% Notebook 10% Course Workbook Detailed Grading Formula 100-90 = A 89-80 = B 2 79-70 = C 69-60 = D 59 & below = F COURSE OBJECTIVES The focus of this course is; the automotive repair technician has a monumental challenge before him or her to keep abreast of the constantly changing technical advances in the automotive industry. The technician has to comprehend information on the new HiTech electrical systems, the ever- changing mechanical technology and improved materials, which make up a modern day vehicle. The automotive technician has to determine what component part or parts are performing incorrectly by using meters, gauges, and computer test equipment. The technician will need to be able to repair the customer’s vehicle as quickly as possible. Increased vehicle sales caused by the increasing population means increased use of automobiles. Automotive repair technicians are very desirable employees in the current and future workplace. They command high salaries for their expertise of diagnosis and repair of the automobile. Upon completion of this course, the student will: STUDENT LEARNING OUTCOMES: Utilizing appropriate safety procedures, the student will demonstrate familiarity with historical development and career information on the automotive industry; demonstrate safe, professional, and responsible work practices; identify and demonstrate the proper use of shop equipment and tools; identify and describe functions of the vehicle subsystems; demonstrate the use of service publications; identify various automotive fasteners used in industry; and perform automotive maintenance. 1. Academic testing - Students are required to take the COMPAS OR ASSET exam. 2. Academic assistance - Tutoring is available to students requiring assistance by making an appointment with the instructor in the area in question 3. College expectations/responsibilities: Complete Houston Community College Admission form Be dedicated to completing the course of study Committed to read and study at least 4 hours each day Maintain strong attendance, Follow the Automotive Program rules and regulations Strong interpersonal skills Enjoy working with people Cheerful disposition 4. Declaration of major and education plan – Students will be required to contact the counseling office to file a degree plan within the first month of class. 3 Automotive students have a choice of Level 1 certificate or Associate of Applied Science. 5. Financial aid information – You will need a PIN number to apply for financial aid. The link to apply for the pin number is, http://www.pin.ed.gov/PINWebApp/pinindex.jsp Time Saving Suggestions Gather the documents you need. Start with your Social Security Number, driver’s license, income tax returns, bank statements, and investment records. Print a FAFSA on the Web Worksheet. Write in your answers and gather your parents' information then transfer the data to FAFSA on the Web. Plan how to sign your FAFSA. Sign electronically with a Personal Identification Number (PIN) or by mailing in a signature page. Apply for a PIN now! Speed up the process by signing your FAFSA electronically with your PIN. Your parent can sign electronically too. Check your eligibility for federal student aid. Note important deadlines. To meet the Federal Student Aid deadline: Apply as early as possible beginning January 1st of each year. Schools and states have their own deadlines. Contact them for exact deadline dates. Financial Aid Web Page www.FAFSA.ed.gov – Types of Financial Aid There are several Types of Financial Aid available at Houston Community College. Grants are financial aid you don't have to pay back. Work-Study lets you work and earn money to help pay for school. Loans are borrowed money that you must repay with interest. Scholarships are gift aid you don't have to pay back. 4 There are four main sources of financial aid. Federal Government (the largest source of financial aid) State Government Institution Private Entities Satisfactory Academic Progress 1. Grade Point Average (GPA) - Maintain a 2.0 cumulative grade point average. 2. Percentage of attempted courses completed. 3. Complete and pass a minimum of 75% of the courses attempted at Houston Community College. 4. Maximum credit hours needed in which to complete a degree or certificate. 5. Complete all degree or certificate requirements within 150% of the minimum number required to graduate. Scholarships Students will explore various scholarship options available to them through the internet or written publications. Many of these scholarships are available through the government and various discipline specific entities. 6. Career exploration – The automotive repair technician has a monumental challenge before him or her to keep abreast of the constantly changing technical advances in the automotive industry. The technician has to comprehend information on the new Hi-Tech electrical systems, the ever- changing mechanical technology and improved materials, which make up a modern day vehicle. The automotive technician has to determine what component part or parts are performing incorrectly by using meters, gauges, and computer test equipment. The technician will need to be able to repair the customer’s vehicle as quickly as possible. Increased vehicle sales caused by the increasing population means increased use of automobiles. Automotive repair technicians are very desirable employees in the current and future workplace. They command high salaries for their expertise of diagnosis and repair of the automobile. Students will explore various job positions such as bumper to bumper service, specialty areas, and the equipment involved in repairing today’s complex automobiles. In addition, basic job skills necessary to succeed in the automotive workplace will be emphasized. 7. College activities/services - Library, clubs, intramurals, etc. The automotive technology program instructors provide mentoring activities to students by encouraging students to join local automotive clubs and internet forums such as: iatn.com, SCCA, and the NHRA. In addition, students are encouraged to attend automotive events such as the Houston Car Show, and the NHRA drag races at 5 Houston Raceway Park. COURSE POLICIES Attendance policy - Students are expected to attend classes regularly, and to be on time for every class period. Students can be dropped from a class due to excessive absences. Excessive tardiness may be considered absences. Students are responsible for subjects, assignments, and projects covered during their absences. Consult the Student Handbook for more details or visit http://www.hccs.edu/hccs/current-students/student-handbook ABSENCES ARE THE MAXIMUM ALLOWED FOR THIS COURSE. Students can be dropped from the course for absences exceeding the allowable limit of 4 days or 12.5 % of class missed. Tardiness policy- Students who are not present when role is taken will be marked tardy. Three tardies are considered one (1) absence. REQUIREMENT FOR THE SUCCESSFUL, COMPLETION OF AUMT 2328 Have a passing average Take all tests with a passing grade Take the final examination Complete all items on the task list included below to the level indicated Turn in all lab sheets and work required All of the following tasks must be completed to a level of “2 - 5” on the NATEF progress chart. Level 5 meaning that the student can complete each task marked level 5 on the list and can perform the indicated operation with out supervision. Level 4 meaning that the student can complete each task marked level 4 on the list and can perform indicted operation with little supervision. Level 3 meaning that the student demonstrated the completion of task marked level 3. Level 2 meaning that the student had a lecture on that task. Make up policy Students with excused absences must make-up missed work as soon as they return. Make-up work for unexcused absences will be up to the discretion of the instructor. NO EXCEPTIONS, All make up work will be completed before last day of that course. Lab work missed due to absences cannot be made up and the student will receive an F on any lab work missed. Check on your grades often and discuss concerns early. The college expects you to read the catalog and handbook to inform you of all policies. If you experience any problems with your class, please discuss the problem with your instructor. If this is impossible please contact the department chair Carl Clark at 713 718-8110. Academic Honesty Scholastic dishonesty is treated with the utmost seriousness by the instructor and 6 the College. Academic dishonesty includes, but it is not limited to the willful attempt to misrepresent one’s work, cheat, plagiarize, or impede other students’ scholastic progress. Consult the Student Handbook for more details or visit http://www.hccs.edu/hccs/current-students/student-handbook Sexual Harassment Sexual Harassment is a form of sex discrimination that is not tolerated by Houston Community College System. See Student Handbook. Students with Disabilities Any student with a documented disability (e.g. physical, learning, psychiatric, vision, hearing, etc.) who needs to arrange reasonable accommodations must contact the Disability Support Services Office at the beginning of each semester. HCCS faculty members are only authorized to provide the accommodations requested by the Disability Support Services Office. Contact: Kim Ingram, Northline Campus, 8001 Fulton, Houston, TX 77022, (713) 718-8420 kim.ingram@hccs.edu Cell Phones All cell phones must be “muted” “set to vibrate” or “turned off” during class. Cell phone activity during class is deemed disruptive to the academic process and will not be tolerated. If you need to make or receive an emergency call, you must leave the classroom. Calculators This course requires the use of a calculator during class, lab projects, and exams; the student is responsible to bring his/her calculator. Cell phones are not calculators, and are not allowed to be used for that purpose during class, tests, or exams. Student ID Students are required to obtain a Student ID. For additional information, consult the Student Handbook. Parking Rules and Regulations Students are required to follow HCC’s regulations regarding parking and permits. For additional information: http://www.hccs.edu/hccs/about-hcc/police/parking/parking-rules-and-regulations Books, Tools and Supplies Students are required to purchase and bring to class the required textbooks, tools, notebooks, supplies, and writing instruments as required by the instructor. 7 Dress Code Dress code must be appropriate for the class. Students must dress in a way that clothing and accessories do not compromise their safety, and the safety of others. Proper foot wear is required in all laboratories. Course Withdrawal It is the responsibility of the student to officially withdraw from a course before the official withdrawal deadline. A student who does not withdraw from a course by the deadline will receive an “F” as the final grade. Course Repetition Students who repeat a course three (3) or more times will face significant tuition/fee increases. Please ask your instructor/counselor about opportunities for tutoring or other assistance prior to considering course withdrawal, or if you are not receiving passing grades. Refunds You receive a 100 percent refund when your class does not make or when a college error has been made. Refunds are processed as soon as possible and generally are mailed four to six weeks after the last day to apply for a refund. Your refund will be mailed to the address on your student record. A StopPayment Fee of $20 is charged to reissue a refund check that has been mailed to an incorrect address. A refund for fees that are paid by third parties, such as friends or relatives, will be made directly to you. However, if payment of your tuition and fees was made to HCCS directly by a sponsor, donor, or scholarship, the refund will be sent to the source, not to you. For further information concerning refunds see the HCC Student Handbook. Grade Appeal Grade determination and awarding of all grades in the course is clearly the responsibility of the instructor. A student’s grade can be changed only at the discretion of the instructor or as a result of the appeals committee process. Whenever possible, students and instructors should attempt to resolve grade disputes informally. If this is not possible and the student remains dissatisfied, the instructor will notify the student of the student’s right to appeal a final course grade and the procedure for filing an appeal. For Further Information concerning the grade appeal process see the HCC Student Handbook. Classroom & Laboratory Conduct Proper behavior is expected in all classes and laboratories. Foul language and horseplay are not allowed. Making or receiving cell phone calls during class is not allowed. Sleeping in class is not allowed. Students not following these policies will be asked to leave the class. 8 POLICY ON ACADEMIC DISHONESTY Scholastic dishonesty includes but is not limited to, cheating on a test, plagiarism, and collusion. Cheating on a test includes: 1. Copying from another student’s test paper; using, during a test, materials not authorized by the person giving the test. 2. Collaborating with another student during a test without authority. 3. Knowingly using, buying, selling, stealing, transporting, or soliciting in whole or Part the contents of an un-administered test. 4. Bribing another person to obtain a test that is to be administered. Plagiarism means the appropriation of another’s work and the unacknowledged incorporation of that work in one’s own work for credit. Collusion means the unauthorized collaboration with another person in preparing written work offered for credit. Students guilty of academic dishonesty can be given a grade of F or 0 for the particular test or assignment involved. In extreme cases or for repeated violations, guilty students can be assigned a failing grade in a course or recommended for probation or dismissal from the College System (Faculty Handbook P.68) (Student Handbook P.35) Forms and Written: All incomplete shop form, written test, ECT: missing name, date, or instructor name ECT. 5% will be taking off grade for that form or test. All blank lines, blank spaces on each page or form are required to be completed. FINAL EXAMINATION The final examination counts as 25% of the final average for each course. To be set on of the last Wednesday of class (4th and 8th week) of that course. You are required to have one (1) SCANTRON; Form No 882 for each. This form will be use to take your final examination on. Purchase of this form Book Store, Northline Mall Camper, Northeast College. WEEKLY TEST Every MONDAY unless there is a holiday interruption the course weekly test or weekly quiz will be given. TARDY on day of test or quiz will be 10% off score of each test. Test time is for each test is 5:30 PM. You are required to have (14) SCANTRON; Form No 882. Purchase of this form Book Store, Northline Mall Camper, Northeast College. Grades counts for Weekly Test or Quiz are 20% of 9 the final grade. DAILY QUIZZIES All quizzes will be given after each lecture or shop/lab. You are required to have 12 SCANTRON Form No 882. Purchase of this form Book Store, Northline Mall Camper, Northeast College. This daily quiz count as 15% of the final grade average. WORKBOOK: Check weekly on Monday at 7:30 PM. It is the responsible of the student “only” to make sure that his/her workbook is turn in on time. Workbook turn in late will be 10% off score each day each chapter each day, this is only for that week workbook is do. Workbook count 10% of your final grade NOTEBOOK Requirements: Check on Wednesday of 4th and 8th week of course at 7:30 PM Workbook count 5% of your final grade LAB REQUIREMENT TOOL POLICY Student are required by the third week of course on Monday, each student must have at least 95% of 1305 and 2328 tools listed on the tool list, in order to perform any shop tasks. Students that do not have their tools and safety glasses cannot be in shop at any time. The exception to this rule is scholarship students who receive tools at the end of the program. SAFETY GLASSES All A.T.T.C. students must wear OSHA approved safety glasses or safety goggles any time they in the shop. Students must have safety glasses by the second day of class. Students who do not have or purchase safety glasses will not be allowed to do any lab or shop activities and therefore will receive a grade of F for their daily lab grade. DAILY PARTICIPATION: This grade is based upon the student’s willingness to participate in classroom, shop, lab and LRC. 3.125 Daily Point System possible 100 points. No Class Manual, Workbook and Required Material - 3.125. No Tools -3.125, Missing Shop Clean Up - 3.125. Absence - 3.125, Tardy -1.5625, Leaving Early -1.5625. This grade count as 10% of the final grade average SHOP ACTIVITIES: The shop grade is based on a willingness to participate in the shop, clean up of shop, having all tools required AUMT 1305, 2328, work completed, and attendance. This grade counts 20% of the final average. 10 SCANS In keep with regulation set by the State of Texas this course incorporates many SCANS skills. The following is information concerning SCANS competencies. SCANS Matrix Model Program: Credential: Automotive Mechanics — CIP: 47.0604 Automotive Technology--Certificate LIST OF ALL COURSES REQUIRED AND IDENTIFIED COMPETENCIES Competencies Course Number Course Title 1 2 3 4 5 6 7 8 X X X X X X X X AUMT 1305 Introduction to Automotive Technology 8 – BASIC USE OF COMPUTERS 7 – W ORKPLACE COMPETENCIES 6 – PERSONAL QUALITIES 5 – THINKING SKILLS 4 – SPEAKING AND LISTENING 3 – ARITHMETIC OR MATHEMATICS 2 – W RITING 1 – READING .THINKING SKILLS F7. Creative Thinking: Uses imagination freely, combines ideal or information in new ways, makes connections between seemingly unrelated ideas, and reshapes goals in ways that reveal new possibilities. . F7. Creative Thinking - Given a vehicle, lab engine or classroom exercise using the student imagination freely, combines ideal or information in new ways, makes connection between seemingly unrelated ideas, and reshapes goals in way that reveal new possibilities. F7. Creative Thinking – Evaluation The student proceeds through the troubleshooting process for the problem in question. Confirm the complaint ________ 30% 11 Consult labor guide and estimate time to repair Consult proper manual or procedure Inspect vehicle or system in proper order ________ 20% ________ 30% ________ 20 F8, Decision Making: Specifies goals and constraints, generates alternatives, considers risks and evaluates and chooses best alternatives. F8. Decision Making - Given a vehicle, lab engine or classroom exercise the student setting specifies goals and constraints, generates alternatives, considers risks, and evaluates and chooses best alternatives. F8. Decision Making - Evaluation The student proceeds through the troubleshooting process for the problem in question. Confirm the complaint _________ 30% Consult labor guide and estimate time to repair _________ 20% Consult proper manual or procedure _________ 30% Inspect vehicle or system in proper order _________ 20% F9. Problem Solving: Recognizes that a problem exists (i.e., there is a discrepancy between what is and what should or could be), identifies possible reason for the discrepancy and devises and implements a plan to resolve it. Evaluates and monitors progress, and revises plan as indicated by finding. F9. Problem Solving - Given a vehicle, lab engine or classroom exercise the student will describe a vehicle problem. Recognizer that a problem exists (i.e., there is a discrepancy between what is and what should or could be) identifies possible reason for the discrepancy, and devices and implements a plan of action to resolve it. Evaluates and monitors progress, and revises plan indicated by findings. F9. Problem Solving – Evaluation The student proceeds through the troubleshooting process for the problem in question. Confirm the complaint __________ 30% Consult labor guide and estimate time to repair __________ 20% Consult proper manual or procedure __________ 30% Inspect vehicle or system in proper order __________ 20% SHOP SAFETY RULES 1. Eye protection must be worn in the shop 2. When a car is jacked up with a floor jack, jack stands must be used to support the car. The car must be fully supported before any person is under car or any work is done. 12 3. When starting a car, the person starting the car MUST be sitting in the driver seat. 4. Horseplay WILL NOT be tolerated in the shop. 5. All spills should be cleaned up promptly. Never allow spills to remain on the floor. 6. Report all accident to your instructor immediately – even minor accidents. 7. Work clothes should be relatively clean and free of all flammable grease or oil. 8. Make sure all fuel lines and linkages are connected before cranking an engine. Never prime and engine while cranking. 9. If you make a mess – clean it up. 10. After using any drain pan, empty the pan in an appropriate waste storage container, and clean the drain pan 11. Hydraulic lifts are to be left fully up or down over night. If left up, safety stands should be in place. 12. Never leave creeper on the floor. When not in use – stand them up. 13. DO NOT use any tool or piece of equipment that you believe to be unsafe. Report it to your instructor. 14. Before starting an engine in the shop, connect an exhaust hose to tail pipe. Turn on exhaust vents and all ceiling fans. 15. Always use goggle or face shield when grinding, hammering, machining, working under a car, or blowing with shop air. 16. If foreign material becomes lodged in your eye, DON”T rub it. This can cause the particle to scratch the eyes and become embedded deeper. Notify your instructor immediately 17. Don’t work when feeling sick. Inform your instructor of the circumstances. 18. Report unsafe or improper practices to your instructor. 19. Never leave gasoline in an open container. 20. Always have a class “B” fire extinguisher available while working on fuel system or around fuel. 21. To avoid spilling fuel on engine wrap a shop towel around the pressure taps, fitting, when connection and disconnect adapters and all fuel connection 22. Observe precautions for working with flammable liquids. No: smoking, an open flame, electrical sparks, and battery sparks from connecting or disconnecting battery charge, ECT. 23. If you are uncertain about positioning a vehicle on a lift or jack – consult your instructor. 24. An instructor MUST supervise all welding or cutting with oxyacetylene torch. 25. Long hair must be confined (under a Hat, tied back or a hair net). 26. Keep tools, electrical cords and hoses away from moving engine parts. 27. Do not wear loose fitting or flowing clothing that could become 13 entangled in rotating machinery. 28. Material Safety Data sheets are located in the tool room. 29. Rings, watches, bracelets, earring and other jewelry should not be worn in the shop. 30. If you break a tool please inform your instructor or tool room personnel. 31. If a tool or piece of equipment is not working properly please inform your instructor or the tool room personnel. Engine Performance VIII NATEF Hands-On Competency Checklist A8—Engine Performance AUMT 2328 No. Task Description Priority Level of Competency (1 – 5) A. General Engine Diagnosis B. Computerized Engine Controls Diagnosis and Repair C. Ignition System Diagnosis and Repair D. Fuel, Air Induction, and Exhaust Systems Diagnosis and Repair E. Emissions Control Systems Diagnosis and Repair F. Engine Related Service A1 Complete work order to include customer information, vehicle identifying information, customer concern, related service history, cause, and correction. P-1 A6 Diagnose abnormal engine noise or vibration concerns; determine necessary action. P-3 B6 Access and use service information to perform stepby-step diagnosis. P-1 D4 Replace fuel filters. P-2 14 Additional Notes E2 Inspect, test and service positive crankcase ventilation (PCV) filter/breather cap, valve, tubes, orifices, and hoses; perform necessary action. P-2 E1 Diagnose oil leaks, emissions, and driveability concerns caused by the positive crankcase ventilation (PCV) system; determine necessary action. P-2 F6 Perform engine oil and filter change. P-1 A5 Inspect engine assembly for fuel, oil, coolant, and other leaks; determine necessary action. P-2 A14 Verify engine operating temperature; determine necessary action. P-1 A15 Perform cooling system pressure tests; check coolant condition; inspect and test radiator, pressure cap, coolant recovery tank, and hoses; perform necessary action. P-1 E3 Remove and replace thermostat and gasket/seal. P-1 F4 Inspect and test mechanical/electrical fans, fan clutch, fan shroud/ducting, air dams, and fan control devices; perform necessary action. P-1 15 READING ASSIGNMENT AUMT 1305 WEEK CHAPTER WEEK #1 CHAPTER 8 – Basic Electricity and Electronics WEEK #2 CHAPTERS 28 – Automotive Batteries WEEK #3 CHAPTER 29 – Battery Testing and Service WEEK #4 CHAPTER 10 – Vehicle Maintenance, Fluid Service, and Recycling WEEK #5 Reviews; Chapter 8, 28, 29 and 10 WEEK #6 CHAPTER 39 – Cooling System Fundamentals CHAPTER 40 – Cooling System Testing, Maintenance, and Repair WEEK #7 CHAPTER 41 – Lubrication System Fundamentals CHAPTER 42 – Lubrication System Testing, Service, and Repair COURSE OUTLINE AUMT 2328 WEEK #1 / January 10 – 13, 2011 LECTURE - AUMT 2328 Course Syllabus Reading Assignment – Chapter 8; Basic Electricity and Electronics Workbook Assignment – Chapter 8 Lecture – Explain the principles and action of electricity Lecture – Describe the action of basic electric circuits Lecture – Compare voltage, current and resistance Lecture Lecture – Ohm Law WEEK #2, January17 - 20, 2011 Weekly Test – Chapter 8; Basic Electricity and Electronic Workbook – Check; Chapter 8 Quiz – Ohm Law Reading Assignment – Chapter 28 Automotive Batteries Workbook Assignment – Chapter 28 Lecture – Work Order 16 Lab – A-1, P-1: Complete work order to include customer information, vehicle identifying information, customer concern, related service history, cause, and correction. Lab – B6, P-1: Diagnose abnormal engine noise or vibration concerns; determine necessary action. Lecture – Explain the operating principles of a lead-acid battery – Describe the parts of an automotive battery – Compare conventional and maintenance-free batteries – Explain how temperature and other factors affect battery performance – Describe safety practices that should be followed when working with batteries – Visually inspection a battery for obvious problems – Service battery and case – Safety practices to follow when testing and servicing batteries – Perform battery test; Snap-On AVR Tester Shop – Perform voltage drop test; battery terminal and cable Shop – Battery Drain – Load Test Shop – Clean a battery case and terminal Shop – Charge vehicle automotive battery Shop – Jump start a car using a second battery Shop – Replace defective battery WEEK #3 / January 24 - 27, 2011 TOOL – CHECK January 24, 2011 MONDAY 7:30 PM, SHOP FLOOR Weekly Test – Chapter 28 Automotive Batteries Workbook – Check; Chapter 28 Reading Assignment – Chapter 29 – Battery Testing and Service Workbook Assignment – Chapter 29 Lecture: Use of Electrical Automotive Test Equipment Lecture; Introduction to Automotive Ignition System Lab/LRC - Research Applicable - Vehicle Service Information; Make Graph - NEW Vehicle 7,500 miles or Older Vehicle: Every 3,000 miles Lab/LRC - Worksheet; Electronic Service Information Retrieval Lab/LRC - Research Applicable - Vehicle Service Information; Lab/LRC - Make Graph - NEW Vehicle 7,500 miles or Older Vehicle: Every 3,000 miles Lab/LRC - Worksheet; Electronic Service Information Retrieval WEEK #4 / 31 – February 3, 2011 Weekly Test – Chapter 29 Battery Testing and Service Workbook – Check; Chapter 29 Review: Chapter 8, 28, 29 and 10 17 Workbook Assignment – Chapter 38 Lecture – Identify the major parts of a hybrid drive system Lecture – Explain the construction and operation of hybrid drive assemblies Lecture – Safety measure that must be followed when working on highvoltage hybrid drive system WEEK #5 / February 7 - 10, 2011 Reading Assignment – Chapter 39 Cooling System Fundamentals Workbook Assignment – Chapter 40 Cooling System Testing, Service Lecture – Emission System; HC, CO, NOx, CO2, and O2 Lecture – PCV; Positive Crankcase Ventilation Worksheet; Shop – E2, P-2: Inspect, test and service positive crankcase ventilation (PCV) filter/breather cap, valve, tubes, orifices, and hoses; perform necessary action. Lecture – Engine Vacuum, Compression and Cylinder Leakage Test Worksheet; Shop – Vacuum; Cranking, Idle, Wide-on-throttle, Pack-press, and Deceleration Worksheet; Shop – Cylinder Compression Test Worksheet; Shop – Cylinder Leakage Test WEEK #6 / February 14 - 17, 2011 Weekly Test – Chapter 39 Cooling System Fundamentals Chapter 40 Cooling System Testing, Service, and Repair Workbook – Check: Chapter 39 and 40 Reading Assignment – Chapter 41 Lubrication System Fundamentals Chapter 42 Lubrication System Testing, Service And Repair Lecture – Safety with flammable fuel gasoline Worksheet; Shop – D4, P-2: Replace fuel filters. Worksheet; Shop – A15, P-1: Perform cooling system pressure tests; check coolant condition; inspect and test radiator, pressure cap, coolant recovery tank, and hoses; perform necessary action Worksheet; Shop – A5, P-2: Inspect engine assembly for fuel, oil, coolant, and other leaks; determine necessary action. Worksheet; Shop – A14, P-1: Verify engine operating temperature; determine necessary action. LECTURE - Cooling System: Safety procedures, Verify engine temperature, Perform cooling system pressure test, Check antifreeze, coolant connection, and inspect radiator, pressure test cap, coolant recovery tank and hoses Worksheet; Shop – E3, P-1: Remove and replace thermostat and gasket/seal Worksheet; Shop – F4, P-1: Inspect and test mechanical/electrical fans, fan 18 clutch, fan shroud / ducting, air dams, and fan control devices; perform necessary action WEEK #7 / February 21 - 24, 2011 Weekly Test – Chapter 41 Lubrication System Fundamentals Chapter 42 Lubrication System Testing, Service & Repair Workbook – Check; Chapter 41 and 42 Reading Assignment - Chapter 7 Vehicle Maintenance, Fluid Service, and Recycling Workbook Assignment – Chapter 7 Lecture – Basic parts of lubrication system – Operation of the lubrication system – Characteristics and rating of engine oil – Safety procedures with lubrication system – Common lubrication system problem and symptoms – Measure engine oil pressure – Change and oil and filter Lecture - Introduction to the automotive Fuel System Worksheet; Shop – F6, P-1; Inspect engine assembly for fuel, oil, coolant, and other leaks; determine necessary action. Worksheet; Shop – A6, P-3: Diagnose abnormal engine noise or vibration concerns; determine necessary action. Worksheet; Shop – E1, P-2: Diagnose oil leaks, emissions, and driveability concerns caused by the positive crankcase ventilation (PCV) system; determine necessary action. WEEK #8 / February 28 – March 3, 2011 Weekly Test – Chapter 7 Vehicle Maintenance, Fluid Service, and Recycling Workbook – Check; Chapter 7 Review – Chapter 8, 28, 29, 10, 38, 39, 40, 41, and42 Final Exam 19 AUMT 1305 / 2328 / 2317 / 2334 (SAME NOTEBOOK ALL COURSE) NOTEBOOK (Binder) Name: __________________________________ Date: __________________ 1. Binder 5 Point SECTION OFF ALL OF THE FOLLOWING: 2. Cover Sheet (Change with each course) 5 Point 3. Syllabus 1305/2328/2317/2334 5 Point 4. Notes 1305/2328 15 Point 5. Handouts 1305/2328/2317/2334 a. Ignition System b. Computer System c. Electrical d. Emission System e. Fuel System f. Engine g. Miscellaneous 8.5 Point 8.5 Point 8.5 Point 8.5 Point 8.5 Point 8.5 Point 8.5 Point 6. Neatness and Order 10 Point THE COVER SHEET WILL BE TYPED AND WILL HAVE THE FOLOWING: You’re Name, Class Name, Class Number, Course Number, Instructor Name, Class Times and Dates of Course 20 All students: I HAVE READ & UNDERSTAND THE CONTENTS OF THIS DOCUMENT AS IT RELATES TO AUMT 2328. ANYTHING NOT COVERS IN THIS SYLLABUS SEE STUDENT HANDBOOK. I WILL ABIDE BY THE GUIDELINES SET FORTH BY THIS SYLLABUS (Date)______________ (Printed Name)_________________________ (Signature)_________________________ 21 All students: I HAVE READ & UNDERSTAND THE CONTENTS OF THIS DOCUMENT AS IT RELATES TO AUMT 2328. ANYTHING NOT COVERS IN THIS SYLLABUS SEE STUDENT HANDBOOK. I WILL ABIDE BY THE GUIDELINES SET FORTH BY THIS SYLLABUS (Date)______________ (Printed Name)_________________________ (Signature)_________________________ 22