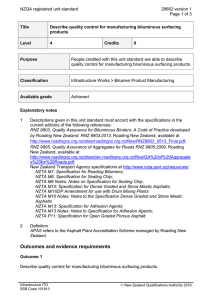

NZQA registered unit standard 23614 version 2 Page 1 of 6

advertisement

NZQA registered unit standard 23614 version 2 Page 1 of 6 Title Undertake foreperson duties on chipseal surfacing construction sites Level 4 Purpose Credits 15 This unit standard is for people working in the pavement surfacing industry as a chipseal surfacing foreperson. People credited with this unit standard are able, as a chipseal surfacing foreperson, to: organise job activities for a chipseal surfacing construction site; prepare for chipseal construction on a site; direct and monitor chipseal construction site safety and environmental protection; direct chipseal surfacing construction activities on site; and monitor and record chipseal surfacing construction activities. Classification Pavement Surfacing > Chipseal Surfacing Available grade Achieved Entry information Critical health and safety prerequisites Unit 20450, Describe safe heating, blending, modification, and transfer of bulk bituminous liquids, or demonstrate equivalent knowledge and skills. Explanatory notes 1 The following legislation and requirements apply to this unit standard, and must be complied with: Health and Safety in Employment Act 1992; Health and Safety in Employment Regulations 1995; Resource Management Act 1991; The Safe Handling of Bituminous Materials Used in Roading – Code of Practice RNZ 9904:2006, Roading New Zealand, available at http://www.roadingnz.org.nz/; Code of Practice for Temporary Traffic Management (CoPTTM), New Zealand Transport Agency, available at http://www.nzta.govt.nz/resources/; Chipsealing in New Zealand, New Zealand Transport Agency, available at http://www.nzta.govt.nz/resources/chipsealing-new-zealand-manual/; New Zealand Transport Authority specifications at http://www.nzta.govt.nz/resources/: NZTA P3: Specification for First Coat Sealing; NZTA P4: Specification for Resealing; NZTA P17: Performance Based Specification for Bituminous Reseals; NZTA Q1: Specification for Quality Assurance for Chipsealing; Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 23614 version 2 Page 2 of 6 NZTA Q1 Notes & NZTA Q2 Notes: Notes to Specifications for Quality Assurance for Chipsealing and Hot Mix Asphalt; Site safety plan; Traffic management plan. Any legislation or other requirements superseding any of the above will apply, pending the review of this unit standard. 2 Assessment against this unit standard must be based on evidence from a workplace context. 3 Definitions Chipseal surfacing foreperson refers to a person who works on chipseal construction sites and reports to a supervisor. The foreperson is skilled in chipseal surfacing, and has defined responsibilities for job organisation, job safety, issuing instructions, work performance, work production, documentation, and quality control, with authority to direct others on site and limited authority for decision making relating to chipseal surfacing construction activities. Company procedures refers to all documented policies, procedures, and methodologies of the candidate’s employer at the time of training including but not limited to those relating to health, safety, environment, quality, and operations. Job requirements take account of site conditions to meet contract specifications, and accord with procedures and work instructions written in quality manuals. Outcomes and evidence requirements Outcome 1 Organise job activities for a chipseal surfacing construction site as a chipseal surfacing foreperson. Evidence requirements 1.1 Support activities for chipseal surfacing are organised in accordance with the work programme and confirmed job requirements. Range activities may include but is not limited to – delivery of chip, delivery of binder, temporary traffic management, removal of surplus chip, roadmarking; includes but is not limited to – sufficient materials on site or in transit to complete the job. 1.2 Temporary traffic management for chipseal surfacing activities is organised in accordance with the traffic management plan. 1.3 Job activities are organised in accordance with work programme and confirmed job requirements. 1.4 Reporting procedures are organised in accordance with confirmed job requirements and company procedures. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 23614 version 2 Page 3 of 6 Outcome 2 Prepare for chipseal construction on a site as a chipseal surfacing foreperson. Range evidence is required from three sites – a first coat seal, a reseal, and a two coat seal. Evidence requirements 2.1 Site is inspected for hazards and adverse effects on the environment in accordance with legislation and company procedures. Range 2.2 Site is inspected for constraints that may impact on the use of equipment and the construction process in accordance with company procedures. Range 2.3 climate, pavement shape, geometric constraints, clearances from adjacent structures, live load limitations, vibration, location of utility services. Spraying requirements are communicated to sprayer operator in accordance with company procedures. Range 2.4 hazards and adverse effects – identified in job requirements, identified by site inspections. requirements – spraying limits, spraying pattern, spraying sequence, binder application rates, application rate change points. Work information is communicated to the workforce in accordance with company procedures. Range work information – locations of ancillary sites, limits of the worksite, work programme, job instructions. Outcome 3 Direct and monitor chipseal construction site safety and environmental protection as a chipseal surfacing foreperson. Range evidence is required for at least two chipseal construction sites. Evidence requirements 3.1 Direction ensures that health and safety hazards are controlled and monitored in accordance with the site safety plan and company procedures. Range Infrastructure ITO SSB Code 101813 hazards – identified in job requirements, identified by site inspections, arising during operations. New Zealand Qualifications Authority 2016 NZQA registered unit standard 3.2 23614 version 2 Page 4 of 6 Identified adverse effects on the environment are controlled and monitored in accordance with the site safety plan and company procedures. Range effects – identified in job requirements, identified by site inspections, arising during operations. 3.3 Traffic management plans are implemented and monitored in accordance with the Code of Practice for Temporary Traffic Management and company procedures. 3.4 Stockpiling of chip, loading and unloading of plant and materials, transfer of bitumen in the field, and disposal of waste materials is carried out with consideration for public safety and in accordance with company procedures and legislation. Outcome 4 Direct chipseal surfacing construction activities on site as a chipseal surfacing foreperson. Range sites applying between 5,000 and 10,000 litres of binder per day; evidence is required of one site each for – first coat seal, reseal, two coat seal. Evidence requirements 4.1 Surface preparation is checked against confirmed job requirements. Range 4.2 preparation includes but is not limited to – cleaning, sweeping, minor repairs. Marking and protection are checked against company procedures and confirmed job requirements. Range marking and protection of service covers, protection of adjacent surfaces, roadmarking offsets. 4.3 Resources are mobilised and sequence of operations is controlled in accordance with site safety and traffic management plans, planned work sequences, the work programme, and confirmed job requirements. 4.4 Site clean-up is confirmed as being in accordance with company procedures. Range Infrastructure ITO SSB Code 101813 includes but is not limited to – removal of surplus chip, disestablishment of equipment, clear site, final inspection. New Zealand Qualifications Authority 2016 NZQA registered unit standard 23614 version 2 Page 5 of 6 Outcome 5 Monitor and record chipseal surfacing construction activities as a chipseal surfacing foreperson. Range a site applying between 5,000 and 10,000 litres of binder per day. Evidence requirements 5.1 Bitumen and chip applications are monitored and, where required, consequent adjustments are made in accordance with design and site requirements. 5.2 Weather conditions are monitored and recorded and, where required, consequent adjustments are made to the work programme in accordance with company procedures. 5.3 Material use is monitored and recorded in accordance with company procedures and confirmed job requirements. 5.4 Plant and equipment use and performance are monitored and recorded in accordance with company procedures. 5.5 Extent of completed work is measured and recorded in accordance with company procedures and confirmed job requirements. 5.6 Foreperson reporting requirements are completed in accordance with company procedures and confirmed job requirements. Planned review date 31 December 2016 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 25 May 2007 31 December 2013 Review 2 15 March 2012 N/A Consent and Moderation Requirements (CMR) reference 0101 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 23614 version 2 Page 6 of 6 Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact Infrastructure ITO askus@infratrain.co.nz if you wish to suggest changes to the content of this unit standard. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016