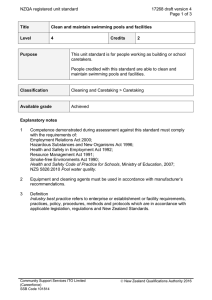

NZQA registered unit standard 20452 version 3 Page 1 of 6

advertisement

NZQA registered unit standard 20452 version 3 Page 1 of 6 Title Spray bitumen for chipseal surfacing using a gangbar sprayer Level 4 Credits 15 Purpose People credited with this unit standard are able to: determine bitumen spraying job requirements; identify, assess, control, and monitor health and safety hazards and adverse effects on the environment of bitumen spraying operations; prepare for and spray bituminous liquids on pavement surfaces using a gangbar sprayer; and complete documentation and reporting. Classification Pavement Surfacing > Chipseal Surfacing Available grade Achieved Entry information Critical health and safety prerequisites Unit 20451, Operate bitumen gangbar sprayer transfer, heating, and blending equipment, or demonstrate equivalent knowledge and skills. Explanatory notes 1 The following legislation and requirements apply to this unit standard, and must be complied with: Hazardous Substances and New Organisms Act 1996; Health and Safety in Employment Act 1992; Resource Management Act 1991; Land Transport Rule: Dangerous Goods 2005 (Rule 45001/1) amendment 2010, 45001/2; Code of Practice for Temporary Traffic Management (CoPTTM), New Zealand Transport Agency, available at http://www.nzta.govt.nz/resources/; BCA E/2:97 Performance of Bitumen Distributors, Roading New Zealand, available on request at http://www.roadingnz.org.nz/; The Safe Handling of Bituminous Materials Used in Roading – Code of Practice 9904:2006, Roading New Zealand, available for purchase at http://www.roadingnz.org.nz/; The Bitumen Safety Handbook; Roading New Zealand, available for purchase at http://www.roadingnz.org.nz/; Chipsealing in New Zealand, New Zealand Transport Agency, available at http://www.nzta.govt.nz/resources/chipsealing-new-zealand-manual/; Contract specifications; Gangbar sprayer manufacturer’s manual; Traffic management plans. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 20452 version 3 Page 2 of 6 Any legislation or other requirements superseding any of the above will apply, pending the review of this unit standard. 2 Personal protective equipment must be used throughout operations in accordance with company procedures. 3 Assessment against this unit standard must be based on evidence from a workplace context. 4 Definitions Bituminous liquids refers to hot straight bitumen, hot cutback bitumen, hot polymermodified bitumen, and emulsified bitumen. Company procedures refers to all documented policies, procedures and methodologies of the candidate’s employer at the time of training including but not limited to those relating to health, safety, environment, quality, and operations. Gangbar sprayer refers to tank wagon specifically built for automatically controlled spraying of bituminous materials on pavement surfaces. The equipment on a gangbar sprayer includes a handbar. Job requirements take account of site conditions to meet contract specifications, and accord with procedures and work instructions written in quality manuals. Outcomes and evidence requirements Outcome 1 Determine bitumen spraying job requirements. Evidence requirements 1.1 Job requirements are determined in accordance with company procedures, Chipsealing in New Zealand, and contract specifications. Range location, limits, binder type, binder quantity, application rate, temperature, run widths, run lengths, tapers, joints, overlaps, quality assurance requirements. 1.2 Temporary traffic management is confirmed in accordance with job requirements. 1.3 Availability of materials, and availability and readiness of other plant required for chipseal construction, are confirmed in accordance with company procedures. 1.4 Acceptance of site for spraying is confirmed in accordance with company procedures and contract requirements. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 20452 version 3 Page 3 of 6 Outcome 2 Identify, assess, control, and monitor health and safety hazards and adverse effects on the environment of bitumen spraying operations. Range operations – gangbar, handbar. Evidence requirements 2.1 Health hazards are identified, assessed, and controlled in accordance with company procedures and legislation. 2.2 Safety hazards are identified, assessed, and controlled in accordance with company procedures, legislation, and The Bitumen Safety Handbook. 2.3 Adverse effects on the environment are identified, assessed, and controlled in accordance with company procedures and legislation. 2.4 Health and safety hazards are monitored in accordance with company procedures and legislation. 2.5 Adverse effects on the environment are monitored in accordance with company procedures and legislation. Outcome 3 Prepare for bitumen spraying. Evidence requirements 3.1 Prior to spraying, services are protected, and masking material is placed for the start and finish of spray runs in accordance with job requirements. 3.2 Gangbar sprayer is positioned and prepared for spray run in accordance with job requirements. 3.3 Spraying equipment is prepared in accordance with the gangbar sprayer manufacturer’s manual, taking into account the number of nozzles selected and type of end nozzle required for width of spray run. 3.4 Spraying controls are set in accordance with the gangbar sprayer manufacturer’s manual, taking into account the selected number of nozzles, required application rate, and combination of pump speed and road speed. 3.5 Prior to spraying, binder temperature and volume are measured and recorded in accordance with the contract specifications and company procedures. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 20452 version 3 Page 4 of 6 Outcome 4 Spray bituminous liquids on pavement surfaces using a gangbar sprayer. Range evidence is required of at least three types of binder, at least ten job sites, a first coat seal, a reseal, and a two-coat seal in any combination. Evidence requirements 4.1 Communications with spray person, driver, and other workers are undertaken on site in accordance with company procedures and job requirements. 4.2 Bituminous liquids are gangbar sprayed onto pavement surfaces in accordance with contract specifications and job requirements. 4.3 Target application rates are confirmed and compared with the actual application rates and any discrepancies are noted and appropriate action is taken. 4.4 Bituminous liquids are hand sprayed on to road surface in accordance with contract specifications. 4.5 Gangbar sprayer performance is verified and recorded in accordance with contract specifications and company procedures. Range record – location, bitumen type, bitumen quantity, bitumen temperature, air temperature, area sprayed, application rate. 4.6 Gangbar sprayer faults that result in deviations from normal performance are identified and corrective actions are taken in accordance with operational requirements and company procedures. 4.7 Positioning of gangbar sprayer for consecutive runs is determined in accordance with site conditions and operational requirements. Range 4.8 operational requirements include but are not limited to – availability of chip, working space for other plant, chip spreading, compaction, traffic flow. Pipework, pump, bitumen filters, and spraying equipment are kept in a condition of readiness for the next spraying operation in accordance with company procedures. Range includes but is not limited to – during operations, between operations, next day. 4.9 At the end of spraying operations all masking and surplus materials are removed and disposed of in accordance with company procedures. 4.10 Vehicle is prepared for travel in accordance with gangbar sprayer manufacturer’s manual, and company procedures. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 20452 version 3 Page 5 of 6 Outcome 5 Complete documentation and reporting. Evidence requirements 5.1 Records and documents are completed in accordance with company procedures. includes but is not limited to – dangerous goods documents, spray dockets, quality assurance data. Range 5.2 Information is communicated to other parties, both internal and external, in accordance with company procedures and contract requirements. Range gangbar sprayer performance, spray dockets, quality assurance data, gangbar sprayer maintenance. Planned review date 31 December 2016 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 27 October 2005 31 December 2013 Revision 2 25 May 2007 31 December 2013 Review 3 15 March 2012 N/A Consent and Moderation Requirements (CMR) reference 0101 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 20452 version 3 Page 6 of 6 Comments on this unit standard Please contact Infrastructure ITO askus@infratrain.co.nz if you wish to suggest changes to the content of this unit standard. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016