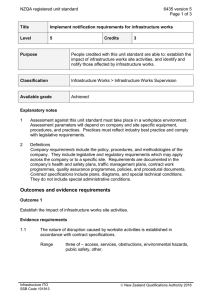

NZQA registered unit standard 17463 version 4 Page 1 of 4

advertisement

NZQA registered unit standard 17463 version 4 Page 1 of 4 Title Operate and control pre-expansion equipment for expanded polystyrene materials Level 2 Credits 8 Purpose People credited with this unit standard are able to: demonstrate knowledge of the operation of pre-expansion equipment; start up, monitor and shut down pre-expansion equipment; and identify, correct and report production faults in an expanded polystyrene moulding operation. Classification Plastics Processing Technology > Expanded Polystyrene Moulding Available grade Achieved Entry information Recommended skills and knowledge Unit 17461, Perform basic process operations for expanded polystyrene moulding. Explanatory notes 1 All work practices must meet enterprise health and safety requirements. 2 Definitions Enterprise means an organisation where training and/or assessment is taking place, and/or where the trainee is employed. Enterprise procedure is defined as actions which comply with the policies, systems, and directives in a particular enterprise. Enterprise procedure must comply with the requirements of the Health and Safety in Employment Act 1992, and subsequent amendments. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA registered unit standard 17463 version 4 Page 2 of 4 Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of the operation of pre-expansion equipment. Evidence requirements 1.1 The principles of pre-expanding polystyrene bead are described. Range 1.2 Expanded polystyrene material additives introduced during pre-expansion are named, and their fundamental purpose is described in accordance with enterprise procedure. Range 1.3 additives – colourants, external lubricants, anti-statics. The components and operation of pre-expansion equipment are described. Range 1.4 principles – heat application, bead softening, blowing agent. components and operation – evidence is required for basic characteristics only. Pre-expansion ancillary equipment and services are identified using enterprise equipment, and their fundamental purpose is described. Range ancillary equipment may include – feed hopper, conveyors, dryers, sieves, aging silos, density measurement equipment, ventilation equipment; services may include – electricity, water, compressed air, vacuum, steam. Outcome 2 Start up, monitor and shut down pre-expansion equipment. Evidence requirements 2.1 Raw material for pre-expansion is selected and verified against product specification, and is loaded in accordance with enterprise procedures. 2.2 Equipment set-up information is interpreted, and the pre-expansion equipment is set up in accordance with enterprise procedure. 2.3 Pre-expansion and ancillary equipment start-up procedures are performed in accordance with enterprise procedure. 2.4 Pre-expansion equipment settings are monitored and adjusted to maintain bead density specification, and are reported in accordance with enterprise procedures. 2.5 Production recording is carried out in accordance with enterprise procedure. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA registered unit standard 17463 version 4 Page 3 of 4 2.6 Pre-expansion and ancillary equipment shut-down procedures are performed in accordance with enterprise procedure. 2.7 Equipment and work area is cleared and cleaned in accordance with enterprise requirements. equipment includes – pre-expansion and ancillary equipment internal and external surfaces; work area may include – floors, stairs, platforms, ledges, intake and output areas, silo storage areas, drains. Range Outcome 3 Identify, correct and report production faults. Evidence requirements 3.1 Routine pre-expansion faults are identified and corrected in accordance with enterprise procedure. routine pre-expansion faults – lumps, collapsed bead, wet bead, bead density variations, blockage from feeder/conveyor; evidence is required for two faults. Range 3.2 Common pre-expansion equipment malfunctions are identified and reported in accordance with enterprise procedure. common equipment malfunctions include – stopped stirrer, no raw material feed, expanded bead conveyor failure, services failure, lump breaker failure, broken or damaged sieve; evidence to be demonstrated for one malfunction, and knowledge of two other malfunctions. Range Planned review date 31 December 2015 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 29 May 2000 31 December 2015 Revision 2 17 March 2004 31 December 2015 Rollover and Revision 3 25 September 2006 31 December 2015 Review 4 21 January 2011 N/A Accreditation and Moderation Action Plan (AMAP) reference 0134 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA registered unit standard 17463 version 4 Page 4 of 4 Please note Providers must be granted consent to assess against standards (accredited) by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Consent requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact Competenz info@competenz.org.nz if you wish to suggest changes to the content of this unit standard. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016