NZQA registered unit standard 23323 version 2 Page 1 of 4

advertisement

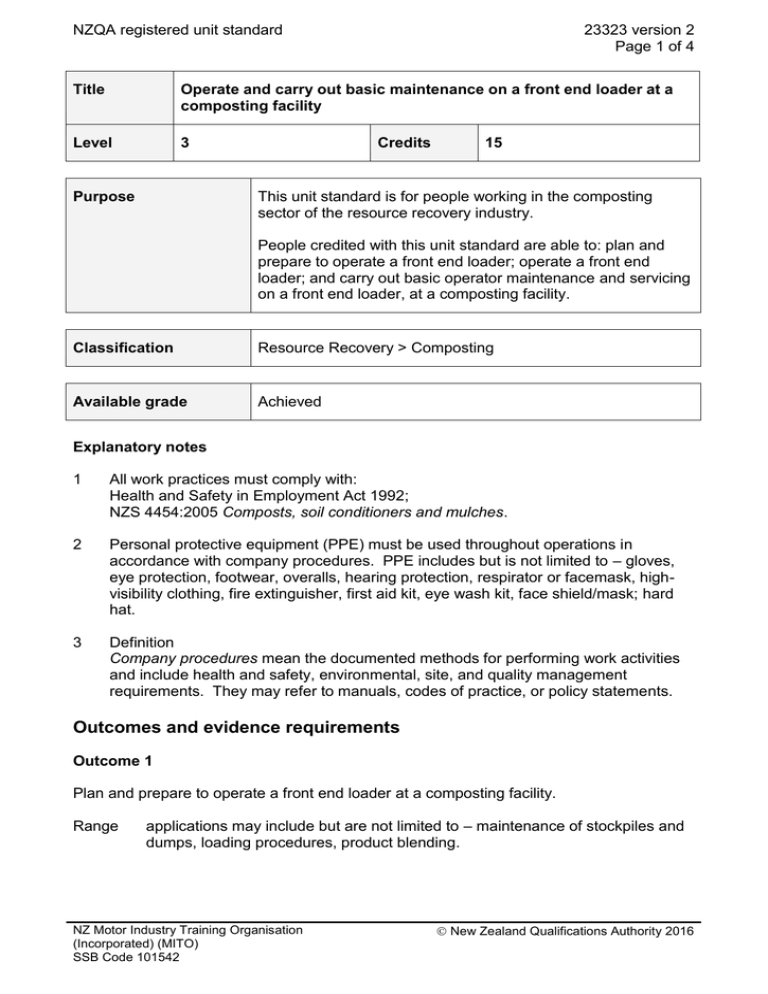

NZQA registered unit standard 23323 version 2 Page 1 of 4 Title Operate and carry out basic maintenance on a front end loader at a composting facility Level 3 Purpose Credits 15 This unit standard is for people working in the composting sector of the resource recovery industry. People credited with this unit standard are able to: plan and prepare to operate a front end loader; operate a front end loader; and carry out basic operator maintenance and servicing on a front end loader, at a composting facility. Classification Resource Recovery > Composting Available grade Achieved Explanatory notes 1 All work practices must comply with: Health and Safety in Employment Act 1992; NZS 4454:2005 Composts, soil conditioners and mulches. 2 Personal protective equipment (PPE) must be used throughout operations in accordance with company procedures. PPE includes but is not limited to – gloves, eye protection, footwear, overalls, hearing protection, respirator or facemask, highvisibility clothing, fire extinguisher, first aid kit, eye wash kit, face shield/mask; hard hat. 3 Definition Company procedures mean the documented methods for performing work activities and include health and safety, environmental, site, and quality management requirements. They may refer to manuals, codes of practice, or policy statements. Outcomes and evidence requirements Outcome 1 Plan and prepare to operate a front end loader at a composting facility. Range applications may include but are not limited to – maintenance of stockpiles and dumps, loading procedures, product blending. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 23323 version 2 Page 2 of 4 Evidence requirements 1.1 Safety rules and regulations for front end loader operation are adhered to in accordance with legislation and company procedures. 1.2 Pre-start checks are carried out in accordance with company procedures. Range walk-around inspections. 1.3 Identified defects are reported and managed in accordance with company procedures. 1.4 Briefings or handover details are received, interpreted, and clarified in accordance with company procedures. 1.5 Work area preparation is carried out in accordance with job specifications and company procedures. Outcome 2 Operate a front end loader at a composting facility. Evidence requirements 2.1 Start-up and parking procedures are carried out in accordance with manufacturer's instructions and/or company procedures. 2.2 Front end loader operations are conducted and controlled in accordance with conditions, equipment operating capacities, and manufacturer's instructions. Range 2.3 Safe operating procedures are demonstrated in accordance with manufacturer's instructions and company procedures. Range 2.4 conditions may include but are not limited to – weather, visibility; evidence is required of night and day operation. safe operating procedures may include but are not limited to – observing site, speed limits, working safely around overhead power lines, working safely around other machines and personnel, conducting safety checks, use of two-way radio for communication, emergency procedures. Loading technique is selected and modified in relation to varying materials, haulage units, material handling facilities, and changing work conditions in accordance with company procedures. Range loading techniques – single and double-sided; haulage units may include but are not limited to – rear dump, belly dumps, road trucks, use of load weigh technology or similar. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 2.5 Towing of equipment or plant is carried out in accordance with company procedures. Range 2.6 23323 version 2 Page 3 of 4 within certified towing connection capacity. Front end loader operations are carried out in accordance with site quality plan and job specifications. Outcome 3 Carry out basic operator maintenance and servicing on a front-end loader at a composting facility. Range basic operator maintenance – work that the operator can undertake without getting a mechanic: may include but is not limited to – greasing moving parts, checking oil levels, cleaning. Evidence requirements 3.1 Inspection is conducted in accordance with manufacturer’s instructions and/or company procedures. 3.2 Identified defects are reported and managed in accordance with company procedures. 3.3 Routine operational servicing and lubrication tasks are carried out in accordance with manufacturer’s instructions and company procedures. 3.4 Basic operator maintenance is carried out in accordance with manufacturer's instructions and company procedures. Range basic operator maintenance – work that the operator can undertake without getting a mechanic; may include but is not limited to – greasing moving parts, checking oil levels, cleaning. 3.5 Records are maintained in accordance with company procedures. 3.6 Vehicle washing and housekeeping are carried out in accordance with company procedures and manufacturer's instructions. Planned review date 31 December 2019 NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 23323 version 2 Page 4 of 4 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 23 April 2007 N/A31 December 2017 Review 2 16 April 2015 N/A Consent and Moderation Requirements (CMR) reference 0114 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the NZ Motor Industry Training Organisation (Incorporated) (MITO) info@mito.org.nz if you wish to suggest changes to the content of this unit standard. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016