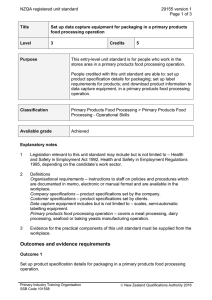

NZQA registered unit standard 19471 version 4 Page 1 of 4

advertisement

NZQA registered unit standard 19471 version 4 Page 1 of 4 Title Reassemble and test electric machines following rewinding Level 4 Purpose Credits 8 This unit standard is intended for people wishing to qualify in the electrical industry in motor rewinding and repair. It is for people who have responsibility for the reassembly and testing of electric machines following rewinding. People credited with this unit standard are able to: – reassemble electric machines; and – test electric machines. Classification Electrical Engineering > Electrical Machines Available grade Achieved Entry information Recommended skills and knowledge The Skills Organisation SSB Code 100401 Assessment against this unit standard should not be undertaken until competency in the following unit standards has been achieved, or equivalent knowledge and skills demonstrated: Unit 750, Demonstrate knowledge of electrical test instruments and take measurements Unit 1184, Test, locate and diagnose faults in electrical machine windings Unit 6401, Provide first aid Unit 6402, Provide resuscitation level 2 Unit 15848, Demonstrate knowledge of safeguards for use with portable electrical appliances Unit 15851, Demonstrate knowledge of electrical safety and safe working practices for electrical workers Unit 15852, Isolate and test low-voltage electrical sub-circuits Unit standards 10933-10936 Electrical Service Technicians Technical – A Unit standards 10937-10940 Electrical Service Technicians Technical – B Unit 27349, Demonstrate knowledge of theory and legislation for registration of electrical service technicians. New Zealand Qualifications Authority 2016 NZQA registered unit standard 19471 version 4 Page 2 of 4 Explanatory notes 1 Achievement of this unit standard does not by itself imply that trainees may legally perform prescribed electrical work in their own right. Until they are registered and licensed under the Electricity Act 1992, trainees are assisting, and must work under the supervision of a Supervisor of Electrical Work when carrying out prescribed electrical work. If the prescribed electrical work in question is carried out for reward the Supervisor of Electrical Work must hold a valid practising licence. 2 This unit standard is one of a series designed to cover the rewinding of electric machines normally removed to a motor rewinding workshop. The unit standards and the recommended sequence are as follows: Unit 1184, Test, and locate and diagnose faults in electrical machine windings Unit 1185, Prepare electrical machines for rewinding Unit 19470, Rewind electric machines Unit 19471, Reassemble and test electric machines following rewinding. Reinstallation and commissioning are covered in: Unit 2014, Overhaul a.c. rotating machines and control equipment Unit 5928, Overhaul d.c. rotating machines and control equipment. 3 References Electricity Act 1992; Electricity (Safety) Regulations 2010; New Zealand Electrical Codes of Practice (available from Ministry of Business, Innovation and Employment);AS/NZS 3760:2010, In-service safety inspection and testing of electrical equipment, including Amendment 1; 4 Definitions Current regulations and standards – those requirements of the above legislation, standards, and codes, applied to the context in which the term is used. Industry practice – those practices that competent practitioners within the industry recognise as current industry best practice. Machines – motors, generators, regulators, transformers, and other similar equipment having windings. Specifications – machine specifications, maintenance instructions, or bearing manufacturer's recommendations relating to removal, cleaning, testing, and fitting of bearings and seals, and the types of lubricants to be used. 5 Assessment a The machines chosen are left to the discretion of the assessor, but must be sufficient to assess competence in all outcomes of the unit. b Performance in relation to the outcomes of this unit standard must comply with the Health and Safety in Employment Act 1992, associated regulations and any applicable company safety and health procedures. Outcomes and evidence requirements Outcome 1 Reassemble electric machines. The Skills Organisation SSB Code 100401 New Zealand Qualifications Authority 2016 NZQA registered unit standard 19471 version 4 Page 3 of 4 Evidence requirements 1.1 Rotating components are statically and/or dynamically balanced in accordance with specifications and industry practice. Range typical components – armatures, rotors, fans, pulleys. 1.2 Parts are assembled in a logical sequence in accordance with industry practice and specifications. 1.3 Parts are aligned and set to specified tolerances. 1.4 Tightness of each fastening is verified in accordance with motor specifications and/or industry practice. 1.5 Machine is lubricated in accordance with specifications and industry practice. 1.6 Testing of windings and internal connections is completed in accordance with industry practice, specifications and current regulations and standards. Outcome 2 Test electric machines. Evidence requirements 2.1 Testing confirms that all requirements of current regulations and standards have been met, and that the machine is safe to reconnect to the supply. Range 2.2 Testing includes verification of machine performance against specifications or records of previous performance, in accordance with industry practice. Range 2.3 tests – continuity, polarity, insulation resistance, earthing; phase sequence of three-phase supply. typical tests – inductance, impedance, dynamometer test or in situ connected-load test; measurements to compare power factor, line current, speed, and output with values stated on rating plate; temperature-rise test; checks using sight, sound, touch, vibration. Results of tests are documented in accordance with company requirements; and compared with manufacturers’ specifications. Planned review date The Skills Organisation SSB Code 100401 31 December 2014 New Zealand Qualifications Authority 2016 NZQA registered unit standard 19471 version 4 Page 4 of 4 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 26 August 2002 31 December 2013 Review 2 22 August 2008 N/A Rollover and Revision 3 15 March 2012 N/A Revision 4 15 January 2014 N/A Consent and Moderation Requirements (CMR) reference 0003 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact The Skills Organisation reviewcomments@skills.org.nz if you wish to suggest changes to the content of this unit standard. The Skills Organisation SSB Code 100401 New Zealand Qualifications Authority 2016