Describe abstraction and pre-treatment processes for potable water

advertisement

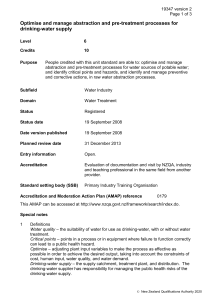

24898 version 1 Page 1 of 5 Describe abstraction and pre-treatment processes for potable water Level 5 Credits 8 Purpose People credited with this unit standard are able to describe: abstraction and pre-treatment processes for surface water sources of potable water; abstraction and pre-treatment processes for groundwater sources of potable water; and processes affecting water quality, and management techniques for raw water reservoirs; and identify critical points, hazards, preventive actions, and corrective actions of processes and management points. Subfield Water Industry Domain Drinking-Water Status Registered Status date 19 September 2008 Date version published 19 September 2008 Planned review date 31 December 2013 Entry information Open. Replacement information This unit standard and unit standard 24897 replaced unit standard 18448. Accreditation Evaluation of documentation and visit by NZQA, industry and teaching professional in the same field from another provider. Standard setting body (SSB) Primary Industry Training Organisation Accreditation and Moderation Action Plan (AMAP) reference 0179 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 References Legislation relevant to this unit standard includes but is not limited to the Health Act 1956, and Resource Management Act 1991. Ministry of Health Public Health Risk Management Plan Guides for Drinking-Water Supplies (PHRMPGs): S1.1, Surface and groundwater sources; S2, Development of new supplies; New Zealand Qualifications Authority 2016 24898 version 1 Page 2 of 5 P11, Surface water abstraction – rivers, streams and infiltration galleries; P4.2, Destratification. Drinking-Water Standards for New Zealand 2000 and 2005, Ministry of Health, Wellington. Guidelines for Drinking-Water Quality Management for New Zealand, Ministry of Health, Wellington, 2000, Chapter 3.4.2. Proposed/National Environmental Standard for Human Drinking-water Sources, Ministry for the Environment, available from http://www.mfe.govt.nz. 2 Definitions Water quality – the suitability of water for use as drinking-water, with or without water treatment. Critical points – points in a process or in equipment where failure to function correctly can lead to a public health hazard. Organisational procedures – instructions to staff, and procedures which are documented in memo or manual format and are available in the workplace. These requirements include but are not limited to – site specific requirements, manufacturers’ specifications, product quality specifications, and legislative or regulatory requirements. Elements and performance criteria Element 1 Describe abstraction and pre-treatment processes for surface water sources of potable water. Performance criteria 1.1 Design features of hardware for surface water abstractions are described in terms of their function. Range 1.2 Pre-treatment processes are described in terms of their purpose in relation to raw water quality, and the effects they may have on water quality. Range 1.3 six design features from – river intake types, weirs, pumps and wet wells, mechanical and fixed screens, infiltration galleries, rough filtration, intake towers, spillways, spring head, fish passes, raw water pipelines. raw water quality variations, aeration, consent limits, flow control; control of – pathogens, pollutants, suspended matter, turbidity, algae, taste and odour, aeration, iron and manganese. Roof water is described in terms of the factors which cause contamination, and control measures. Range includes but is not limited to – possums, birds, lead flashing, gutter debris, spray drift; control measures include but are not limited to – first flush diverters, tank design. New Zealand Qualifications Authority 2016 24898 version 1 Page 3 of 5 Element 2 Describe abstraction and pre-treatment processes for groundwater sources of potable water. Performance criteria 2.1 The construction of a well is described in terms of physical structures, their placement for effectiveness, and processes. Range 2.2 Groundwater aeration for pH, carbon dioxide, manganese, iron, and ammonia is described in terms of process efficiency and plant operations. Range 2.3 physical structures – screen types, pump, power cables, pipework, check valves; processes – developing, drawdown. aerators – cascade, spray; process efficiency – head losses, equipment footprints. Groundwater chemical treatment for pH, carbon dioxide, manganese, iron, and ammonia is described in terms of process chemistry, and plant operations. Range process chemistry – oxidation, alkali addition; plant operation – dosing systems. Element 3 Describe processes affecting water quality, and management techniques for raw water reservoirs. Performance criteria 3.1 The changes in water quality due to raw water storage in reservoirs are identified in terms of features, physical, chemical, and micro-biological parameters. Range includes but is not limited to – features – water movement, turnover; control – turbidity reduction, mixing, inflow dilution, depth selection, multiple depth take-offs, multiple take-offs, ‘point’ and linear aerators, circulation, retention time, chemical dosing and mixing; physical parameters – stratification, temperature, sunlight, tastes, odours; chemical parameters – nutrients, algal and cyanobacterial growth, tastes, odours, toxicity; microbiological parameters – cyanobacterial growth, tastes, odours. New Zealand Qualifications Authority 2016 24898 version 1 Page 4 of 5 3.2 Assessment of the effectiveness of raw water reservoir management tools determines their effectiveness in controlling deterioration of raw water, and corresponding improvement processes required. Range tools include but are not limited to – multiple outlets, multidepth outlets, point source aeration, linear aerators, monitoring; deterioration processes – thermocline formation, formation of an anoxic hypolimnion and buildup of dissolved manganese, algal and cyanobacterial blooms; improvement processes – sedimentation, oxidation, ultraviolet irradiation, circulation, aeration, dilution; control – turbidity reduction, mixing, inflow dilution, depth selection, multiple depth take-offs, multiple take-offs, ‘point’ and linear aerators, circulation, retention time, chemical dosing and mixing. Element 4 Identify critical points, hazards, preventive actions, and corrective actions of processes and management points. Range groundwater management and abstraction processes, surface raw water management and abstraction processes. Performance criteria 4.1 The critical points of processes and management points are identified in accordance with organisational procedures. 4.2 The hazards at each critical point are identified in terms of the causes of the events leading to their appearance, and the risk factors. 4.3 The preventive and corrective actions for events related to each hazard are identified. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. New Zealand Qualifications Authority 2016 24898 version 1 Page 5 of 5 Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Primary Industry Training Organisation standards@primaryito.ac.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016