NZQA registered unit standard 28907 version 1 Page 1 of 4

advertisement

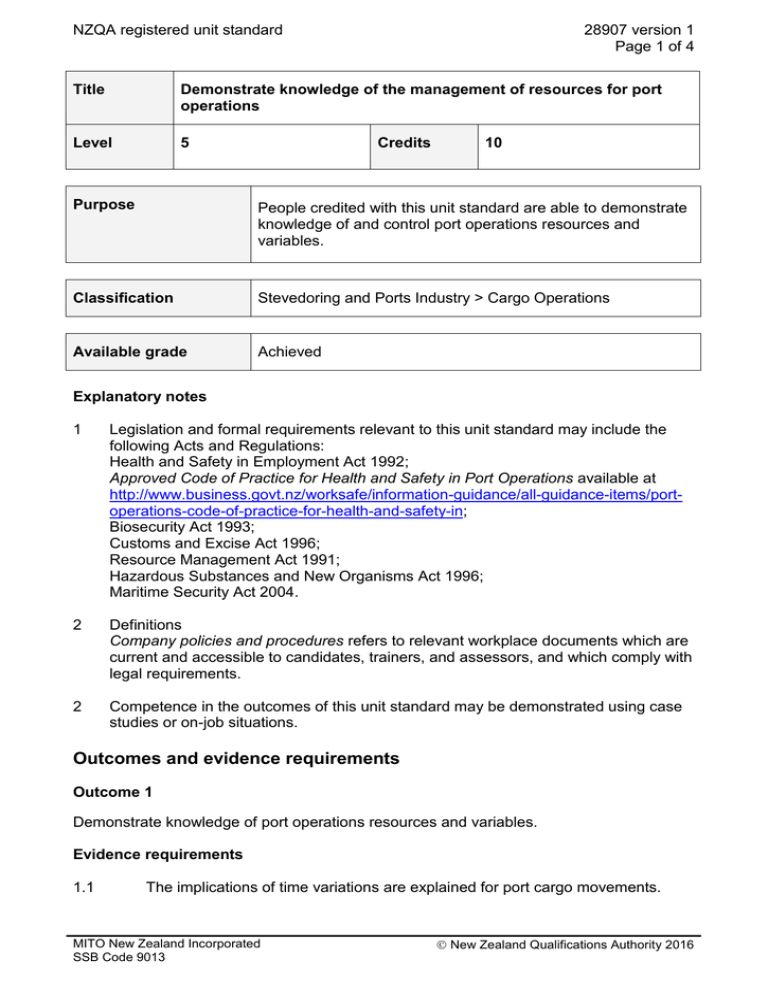

NZQA registered unit standard 28907 version 1 Page 1 of 4 Title Demonstrate knowledge of the management of resources for port operations Level 5 Credits 10 Purpose People credited with this unit standard are able to demonstrate knowledge of and control port operations resources and variables. Classification Stevedoring and Ports Industry > Cargo Operations Available grade Achieved Explanatory notes 1 Legislation and formal requirements relevant to this unit standard may include the following Acts and Regulations: Health and Safety in Employment Act 1992; Approved Code of Practice for Health and Safety in Port Operations available at http://www.business.govt.nz/worksafe/information-guidance/all-guidance-items/portoperations-code-of-practice-for-health-and-safety-in; Biosecurity Act 1993; Customs and Excise Act 1996; Resource Management Act 1991; Hazardous Substances and New Organisms Act 1996; Maritime Security Act 2004. 2 Definitions Company policies and procedures refers to relevant workplace documents which are current and accessible to candidates, trainers, and assessors, and which comply with legal requirements. 2 Competence in the outcomes of this unit standard may be demonstrated using case studies or on-job situations. Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of port operations resources and variables. Evidence requirements 1.1 The implications of time variations are explained for port cargo movements. MITO New Zealand Incorporated SSB Code 9013 New Zealand Qualifications Authority 2016 NZQA registered unit standard Range 1.2 capacity, availability, absenteeism, skill and knowledge, allocation and monitoring, contingency planning, utilisation, downtime, team dynamics and composition, cross-organisational communication, seasonality, managing resource allocation in peaks and troughs, identifying training requirements, planning for confined space, working at heights. Machinery resource considerations are identified for a cargo movement at a port and machinery requirements are determined for the safe and efficient operation of cargo movements within a port according to company policies and procedures. Range 1.5 management of space, marshalling cargo, space constraint management, congestion, yard rotation, change of port, preparing cargo for vessel sequencing, prioritisation, identification of issues, fumigation, optimisation of available space. Human resource considerations are identified for a cargo movement at a port, and human resource requirements are determined for the safe and efficient operation of cargo movements within a port according to company policies and procedures. Range 1.4 time capacity, supply chain consequential effects, flow-on effect deadlines, tides, resource implications, other operations, cargo prioritisation and sequencing, managing resource allocation in peaks and troughs, fumigation, time critical cargos, damaged cargo, overweight and oversized cargo, cargo time sensitivity (deterioration effects), perishability, productivity and exchange rates, ship movement effects (late arrival and early departure contingency), congestion, optimisation. The effect of cargo movement variables on storage in a port yard is explained. Range 1.3 28907 version 1 Page 2 of 4 fitness for purpose, safety, maintenance, capability, capacity, availability, cost implications, back up availability, breakdown management, environmental response, cross organisational communication, prioritisation, seasonality. Weather and environmental effects are identified in relation to shipping movements at a port and contingency and planning is explained according to company policies and procedures. Range effects include – shipping movements delays, precautions, effects on cargo, cargo loading and stacking, segregation, port exposure, mooring and lashing, biosecurity/prevalence of insects, seasonality, temperature effects, health and safety of personnel. MITO New Zealand Incorporated SSB Code 9013 New Zealand Qualifications Authority 2016 NZQA registered unit standard 28907 version 1 Page 3 of 4 Outcome 2 Control port operations resources and variables. Evidence requirements 2.1 Time capacity is controlled for port cargo movements in accordance with logistic variables. Range 2.2 Resource capacity is controlled for port cargo movements in accordance with logistical variables. Range 2.3 five of – capacity, availability, absenteeism, skill and knowledge, allocation and monitoring, contingency planning, utilisation, downtime, team dynamics and composition, cross-organisational communication, seasonality, managing resource allocation in peaks and troughs, identifying training requirements, planning for confined space, working at heights. Machinery resources are controlled for port cargo movements in accordance with logistical variables. Range 2.5 control of space, marshalling, sequencing and optimisation. Labour resources are controlled for port cargo movements in accordance with logistical variables. Range 2.4 five of – supply chain consequential effects, flow-on effect deadlines, tides, resource implications, other operations, cargo prioritisation and sequencing, managing resource allocation in peaks and troughs, fumigation, time critical cargos, damaged cargo, overweight and oversized cargo, cargo time sensitivity (deterioration effects), perishability, productivity and exchange rates, ship movement effects (late arrival and early departure contingency), congestion, optimisation. five of – fitness for purpose, safety, maintenance, capability, capacity, availability, cost implications, back up availability, breakdown management, environmental response, cross organisational communication, prioritisation, seasonality. Weather and environmental issues are managed for port cargo movements in accordance with logistical variables. Range five of – shipping movement delays, precautions, effects on cargo, cargo loading and stacking, segregation, port exposure, mooring and lashing, biosecurity/prevalence of insects, seasonality, temperature effects, health and safety of personnel. MITO New Zealand Incorporated SSB Code 9013 New Zealand Qualifications Authority 2016 NZQA registered unit standard Planned review date 28907 version 1 Page 4 of 4 31 December 2020 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 17 September 2015 N/A Consent and Moderation Requirements (CMR) reference 0145 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMRs). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the NZ Motor Industry Training Organisation (Incorporated) (MITO) info@mito.org.nz if you wish to suggest changes to the content of this unit standard. MITO New Zealand Incorporated SSB Code 9013 New Zealand Qualifications Authority 2016