PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate basic knowledge of solid

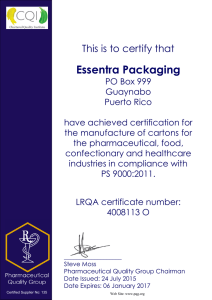

advertisement

21367 28-Jun-16 1 of 4 PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate basic knowledge of solid and liquid pharmaceutical and allied products manufacturing level: 1 credit: 3 planned review date: May 2007 sub-field: Pharmaceutical and Allied Products purpose: People credited with this unit standard are able to demonstrate basic knowledge of solid and liquid pharmaceutical and allied products manufacturing. entry information: Recommended: Unit 21071, Follow basic regulatory requirements in pharmaceutical and allied products manufacturing, or demonstrate equivalent knowledge and skills. accreditation option: Evaluation of documentation by NZQA. moderation option: A centrally established and directed national moderation system has been set up by the Competenz Incorporated. special notes: Competenz unit designation is PAMM1. New Zealand Qualifications Authority 2016 21367 28-Jun-16 2 of 4 PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate basic knowledge of solid and liquid pharmaceutical and allied products manufacturing Elements and Performance Criteria element 1 Demonstrate basic knowledge of solid and liquid pharmaceutical and allied products manufacturing. performance criteria 1.1 The common physical forms of solid and liquid pharmaceutical and allied products are named. Range: 1.2 Types of processes used for the manufacture of solid pharmaceutical and allied products are identified, and their basic purpose and an example of the equipment used for each process, are described. Range: 1.3 solid – powders, granules, tablets, capsules; liquid – solutions, suspensions, gels, lotions, creams, pastes, capsules. types of processes – dispensing, mixing, blending, sieving, granulating, milling, drying, tabletting, coating, extruding, encapsulating; evidence is required for five types of processes. Types of processes used for the manufacture of liquid pharmaceutical and allied products are identified, and their basic purpose and an example of the equipment used for each process, are described. Range: types of processes – dispensing, mixing, homogenising, emulsifying, dispersing, mechanical separation, thermal separation, fermentation, extraction, evaporation, crystallisation, filtration; evidence is required for five types of processes. New Zealand Qualifications Authority 2016 21367 28-Jun-16 3 of 4 PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate basic knowledge of solid and liquid pharmaceutical and allied products manufacturing 1.4 Basic types of tests used during the manufacture of solid and liquid pharmaceutical and allied products and their purpose, are outlined. Range: 1.5 The types of solid and liquid pharmaceutical and allied products produced at the enterprise are named. Range: 1.6 types of tests – appearance, contaminants, uniformity of content, weight, moisture content, bulk density, particle size distribution, specific gravity, thickness, hardness, dissolution, friability, disintegration, pH, viscosity, odour, conductivity; evidence is required for five basic types of tests. solid products may include – powders, granules, tablets, capsules; liquid products may include – solutions, suspensions, gels, lotions, creams, pastes, capsules. The types of processes used to manufacture solid and liquid pharmaceutical and allied products produced at the enterprise are named. Range: types of processes may include – dispensing, mixing, blending, sieving, granulating, milling, drying, tabletting, coating, extruding, encapsulating, homogenising, emulsifying, dispersing, mechanical separation, thermal separation, fermentation, extraction, evaporation, crystallisation, filtration. Comments on this unit standard Please contact Competenz info@competenz.org.nz if you wish to suggest changes to the content of this unit standard. Please Note Providers must be accredited by the Qualifications Authority or a delegated interinstitutional body before they can register credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by the Qualifications Authority before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. New Zealand Qualifications Authority 2016 21367 28-Jun-16 4 of 4 PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate basic knowledge of solid and liquid pharmaceutical and allied products manufacturing Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for providers wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. This unit standard is covered by AMAP 0134 which can be accessed at http://www.nzqa.govt.nz/site/framework/search.html. New Zealand Qualifications Authority 2016