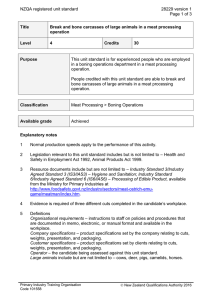

NZQA registered unit standard 28254 version 1 Page 1 of 5

advertisement

NZQA registered unit standard 28254 version 1 Page 1 of 5 Title Audit meat processing systems for compliance with Meat Industry Standards Level 5 Purpose Credits 20 This unit standard is for supervisors and compliance staff who are employed in a meat processing operation and are required to audit the compliance systems. People credited with this unit standard are able to: demonstrate knowledge of compliance auditing; prepare to carry out a compliance audit against Meat Industry Standards; carry out sampling procedures for a compliance audit; carry out antemortem checks for a compliance audit; carry out SPCS checks for a compliance audit; carry out meat inspection checks for a compliance audit; and report on compliance audit findings in a meat processing operation. Classification Meat Processing > Meat Quality Available grade Achieved Explanatory notes 1 2 3 Legislation relevant to this unit standard includes but is not limited to – Animal Products Act 1999, Animal Welfare Act 1999. Resource documents include but are not limited to – Industry Standard 3/Industry Agreed Standard 3 (IS3/IAS3) – Hygiene and Sanitation; Industry Standard 4 – Procurement of Animals for Food; Industry Standard 5 – Slaughter and Dressing; Industry Standard 6/Industry Agreed Standard 6 (IS6/IAS6) – Processing of Edible Product; Industry Standard 7 – Byproducts, Industry Standard 8 – Quality Assurance; Industry Standard 9 – Storing and transport, available from the Ministry for Primary Industries at http://www.foodsafety.govt.nz/industry/sectors/meatostrich-emu-game/meatman/index.htm. Definitions Organisational requirements – instructions to staff on policies and procedures that are documented in memo, electronic, or manual format and available in the workplace. Client – the person or organisation requesting the audit. MIS – meat industry standards. ISL – injection site lesion. SPCS – statistical process control system. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA registered unit standard 28254 version 1 Page 2 of 5 Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of compliance auditing in a meat processing operation. Evidence requirements 1.1 Compliance auditing is explained in terms of the purpose and benefits for the organisation. 1.2 The process for compliance auditing is outlined in terms of the roles and responsibilities of all parties. Range parties include but are not limited to – auditors, organisation, client. Outcome 2 Prepare to carry out a compliance audit against meat industry standards in a meat processing operation. Evidence requirements 2.1 Previous audit documentation is reviewed to determine any open action points or repeated defects in accordance with organisational requirements. 2.2 Animal Product Act warrants are checked for compliance in accordance with regulatory and organisational requirements. 2.3 Data on regulatory activity, diseases, and defects is collected in accordance with organisational requirements. Outcome 3 Carry out sampling procedures for a compliance audit in a meat processing operation. Evidence requirements 3.1 Samples are collected in accordance with the sampling plan. 3.2 Any suspect samples are sealed in accordance with organisational requirements. 3.3 Sampling collection and dispatch process is checked against the training log in accordance with organisational requirements. Range sampling process includes but is not limited to – water sampling, species verification, sulphoramide on-site sampling, ISL, trichinella, cestode lesion sampling, Brucella Ovis sampling. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA registered unit standard 28254 version 1 Page 3 of 5 Outcome 4 Carry out ante-mortem checks for a compliance audit in a meat processing operation. Evidence requirements 4.1 Process for performing ante-mortem checks is examined for compliance against MIS in accordance with organisational requirements. 4.2 Stock lists are verified against completion records in accordance with organisational requirements. 4.3 Communication between ante-mortem and post-mortem inspectors is examined to determine consistency of decision making in accordance with organisational requirements. Outcome 5 Carry out SPCS checks for a compliance audit in a meat processing operation. Evidence requirements 5.1 SPCS decisions are checked for compliance against MIS in accordance with organisational requirements. 5.2 SPCS procedures are checked for compliance against MIS in accordance with organisational requirements. 5.3 SPCS data capture and transmission is checked for completeness in accordance with organisational requirements. 5.4 SPCS post-check procedures and records are checked for completeness in accordance with organisational requirements. 5.5 SPCS data is calibrated in accordance with organisational requirements. Outcome 6 Carry out meat inspection checks for a compliance audit in a meat processing operation. Evidence requirements 6.1 Meat inspection procedures are checked against on-site practice in accordance with organisational requirements. 6.2 Communication between meat inspectors is examined to determine consistency of decision making in accordance with organisational requirements. 6.3 Inventory of detained product is checked for compliance against MIS in accordance with organisational requirements. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA registered unit standard 28254 version 1 Page 4 of 5 6.4 Equipment and workstations are checked for hygiene and sanitation compliance in accordance with organisational requirements. 6.5 Brand inventory is checked to ensure brand control is in accordance with organisational requirements. 6.6 Security register is checked for compliance with site security system in accordance with organisational requirements. 6.7 Meat product batches are checked for compliance against MIS in accordance with organisational requirements. 6.8 Process for identifying diseases and defects for retention, trimming and reinspection is checked against on-site practices in accordance with organisational requirements. 6.9 Process for dealing with condemned material is checked against on-site practices in accordance with organisational requirements. 6.10 Process for detecting and sampling tuberculosis is checked against on-site practice in accordance with organisational requirements. Outcome 7 Report on compliance audit findings in a meat processing operation. Evidence requirements 7.1 Reports identify the extent of compliance with MIS and areas requiring corrective action to ensure compliance, and include recommendations for improvement in accordance with organisational requirements. 7.2 Status of corrective actions identified on previous audits is included in the audit report in accordance with organisational requirements. 7.3 Reports are distributed in accordance with the requirements of the audit plan. Planned review date 31 December 2019 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 27 January 2015 N/A Consent and Moderation Requirements (CMR) reference 0033 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA registered unit standard 28254 version 1 Page 5 of 5 Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Primary Industry Training Organisation standards@primaryito.ac.nz if you wish to suggest changes to the content of this unit standard. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016