NZQA registered unit standard 13521 version 4 Page 1 of 3

advertisement

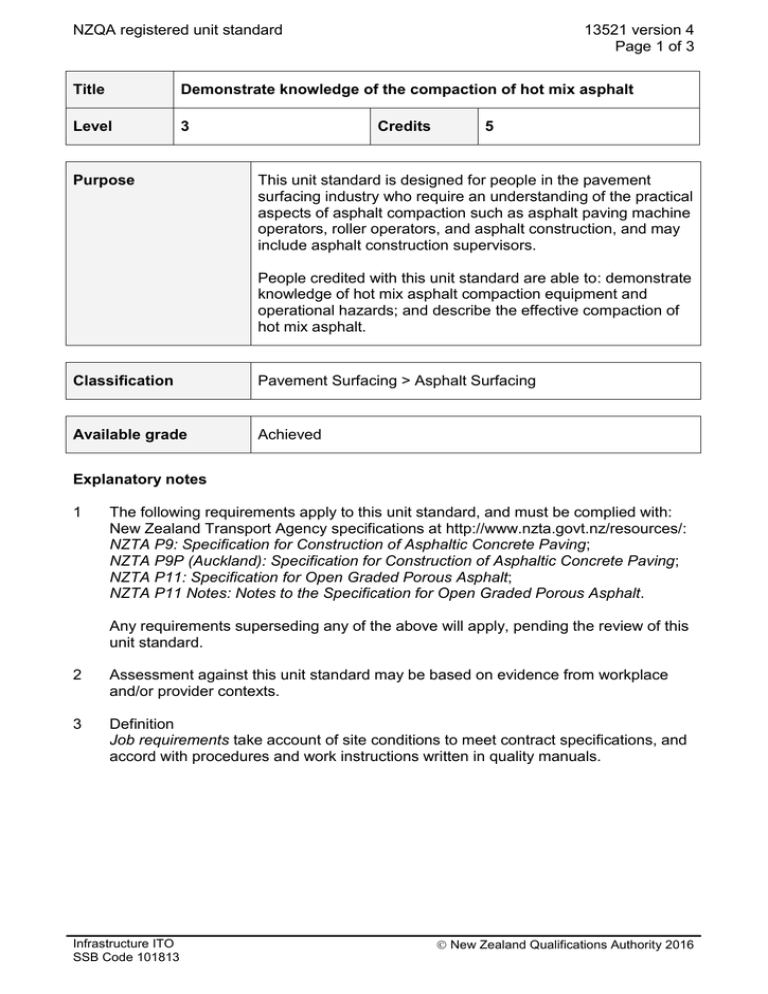

NZQA registered unit standard 13521 version 4 Page 1 of 3 Title Demonstrate knowledge of the compaction of hot mix asphalt Level 3 Purpose Credits 5 This unit standard is designed for people in the pavement surfacing industry who require an understanding of the practical aspects of asphalt compaction such as asphalt paving machine operators, roller operators, and asphalt construction, and may include asphalt construction supervisors. People credited with this unit standard are able to: demonstrate knowledge of hot mix asphalt compaction equipment and operational hazards; and describe the effective compaction of hot mix asphalt. Classification Pavement Surfacing > Asphalt Surfacing Available grade Achieved Explanatory notes 1 The following requirements apply to this unit standard, and must be complied with: New Zealand Transport Agency specifications at http://www.nzta.govt.nz/resources/: NZTA P9: Specification for Construction of Asphaltic Concrete Paving; NZTA P9P (Auckland): Specification for Construction of Asphaltic Concrete Paving; NZTA P11: Specification for Open Graded Porous Asphalt; NZTA P11 Notes: Notes to the Specification for Open Graded Porous Asphalt. Any requirements superseding any of the above will apply, pending the review of this unit standard. 2 Assessment against this unit standard may be based on evidence from workplace and/or provider contexts. 3 Definition Job requirements take account of site conditions to meet contract specifications, and accord with procedures and work instructions written in quality manuals. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 13521 version 4 Page 2 of 3 Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of hot mix asphalt compaction equipment and operational hazards. Evidence requirements 1.1 Types of equipment used for hot mix asphalt compaction are described in terms of their function. Range 1.2 Compaction equipment is described in terms of maintenance requirements when used with hot mix asphalt. Range 1.3 paving machine screed, tamper bars; rollers – static steel, vibrating, rubber-tyred, combination (vibrating drum and rubber-tyred); hand compactor, hand-operated plate compactor. water system, scraper, rollers, tyres, plates, oil, fuel. Hazards of compaction operations are described in terms of controls. Range hazards include but are not limited to – traffic, restricted vision, reversing, equipment instability, ground instability, vibration, excessive live loads. Outcome 2 Describe the effective compaction of hot mix asphalt. Evidence requirements 2.1 Rolling operations are described in terms of sequence, pattern, and the number of rollers to maintain required laying rate while achieving compaction, in accordance with job requirements. Range 2.2 sequence – breakdown, principal, finish; number of passes. Techniques for achieving uniform joints and edges are described. Range joints – transverse, longitudinal, hot, cold. 2.3 Techniques for achieving specified shape, density, and uniformity of mat are described. 2.4 Techniques for avoiding pickup, loss of macro texture, deformation, over-rolling, and cracking of the mat are described. 2.5 Compaction is described in terms of achieving required strength, permeability, and life of an asphalt layer. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 2.6 13521 version 4 Page 3 of 3 Compaction is described in terms of factors that influence the result. factors include but are not limited to – road temperature, ambient temperature, wind, mat thickness, mat temperature, mix type, roller type. Range Planned review date 31 December 2016 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 24 March 1998 31 December 2013 Revision 2 5 January 1999 31 December 2013 Review 3 27 October 2005 31 December 2013 Review 4 15 March 2012 N/A Consent and Moderation Requirements (CMR) reference 0101 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact Infrastructure ITO askus@infratrain.co.nz if you wish to suggest changes to the content of this unit standard. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016