Demonstrate knowledge of metal cutting and gouging processes

advertisement

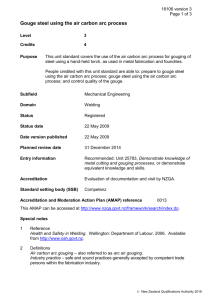

25783 version 1 Page 1 of 4 Demonstrate knowledge of metal cutting and gouging processes Level 3 Credits 2 Purpose This unit standard covers the principles of cutting and gouging metals using the gas, plasma, and air carbon arc processes. People credited with this unit standard are able to demonstrate: knowledge of gas cutting and gouging, plasma arc cutting and gouging, and air carbon arc gouging; and use of cutting and gouging equipment on steel. Subfield Mechanical Engineering Domain Welding Status Registered Status date 22 May 2009 Date version published 22 May 2009 Planned review date 31 December 2014 Entry information Recommended: Unit 21907, Demonstrate and apply knowledge of safe welding procedures under supervision, or demonstrate equivalent knowledge and skills. Accreditation Evaluation of documentation and visit by NZQA. Standard setting body (SSB) Competenz Accreditation and Moderation Action Plan (AMAP) reference 0013 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Reference Health and Safety in Welding. Wellington: Department of Labour, 2006. Available from http://www.osh.govt.nz. New Zealand Qualifications Authority 2016 25783 version 1 Page 2 of 4 2 Definitions Gas cutting – refers to oxygen cutting using a fuel gas such as acetylene or liquid petroleum gas (LPG). Industry practice – safe and sound practices generally accepted by competent trade persons within the fabrication industry. Safe working practice – refers to formal worksite or company safety policies, or the practices established by Health and Safety in Welding or similar codes. 3 The purpose of element 4 is to assess an initial familiarity with this type of equipment. Full competence in cutting and gouging is covered in unit standards 2683 and 18106 respectively. Elements and performance criteria Element 1 Demonstrate knowledge of gas cutting and gouging. Performance criteria 1.1 The principles of gas cutting and gouging are explained with reference to the equipment used. Range equipment – gas cylinders, regulators, flashback, arrestors, hoses, torch, tip, guides. 1.2 The applications, advantages, and disadvantages of gas cutting and gouging are compared with the plasma arc and air carbon arc processes. 1.3 Cutting and gouging parameters and consumables are described for steel in accordance with industry practice. 1.4 Typical faults are described in terms of cause, significance, and corrective action. Element 2 Demonstrate knowledge of plasma arc cutting and gouging. Performance criteria 2.1 The principles of plasma arc cutting and gouging are explained with reference to the equipment used. Range power source, gas supply, electrode, torch (tip, nozzle), guides. 2.2 The applications, advantages, and disadvantages of plasma arc cutting and gouging are compared with the gas and air carbon arc processes. 2.3 Cutting and gouging parameters and consumables are described for steel, stainless steel, and aluminium in accordance with industry practice. New Zealand Qualifications Authority 2016 25783 version 1 Page 3 of 4 2.4 Typical faults are described in terms of cause, significance, and corrective action. Element 3 Demonstrate knowledge of air carbon arc gouging. Performance criteria 3.1 The principles of air carbon arc gouging are explained with reference to the equipment used. Range power source, torch, compressed air, electrode. 3.2 The applications, advantages, and disadvantages of air carbon arc gouging are compared with gouging using the gas and plasma arc processes. 3.3 Gouging parameters and consumables are described for steel in accordance with industry practice. 3.4 Typical faults are described in terms of cause, significance, and corrective action. 3.5 Post-gouging cleanup processes are described in accordance with industry practice. Element 4 Demonstrate use of cutting and gouging equipment on steel. Range equipment may include – gas, plasma arc, air carbon arc. Evidence of use of two types of equipment is required, demonstrating cutting and gouging. Performance criteria 4.1 Equipment is checked and set up in accordance with industry practice. 4.2 Equipment is used in accordance with safe working practice. 4.3 Steel is cut and gouged in accordance with industry practice. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. New Zealand Qualifications Authority 2016 25783 version 1 Page 4 of 4 Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact Competenz qualifications@competenz.org.nz address if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016