NAVIGATION AND SEAMANSHIP Coordinate and monitor mooring, berthing and anchorage operations

advertisement

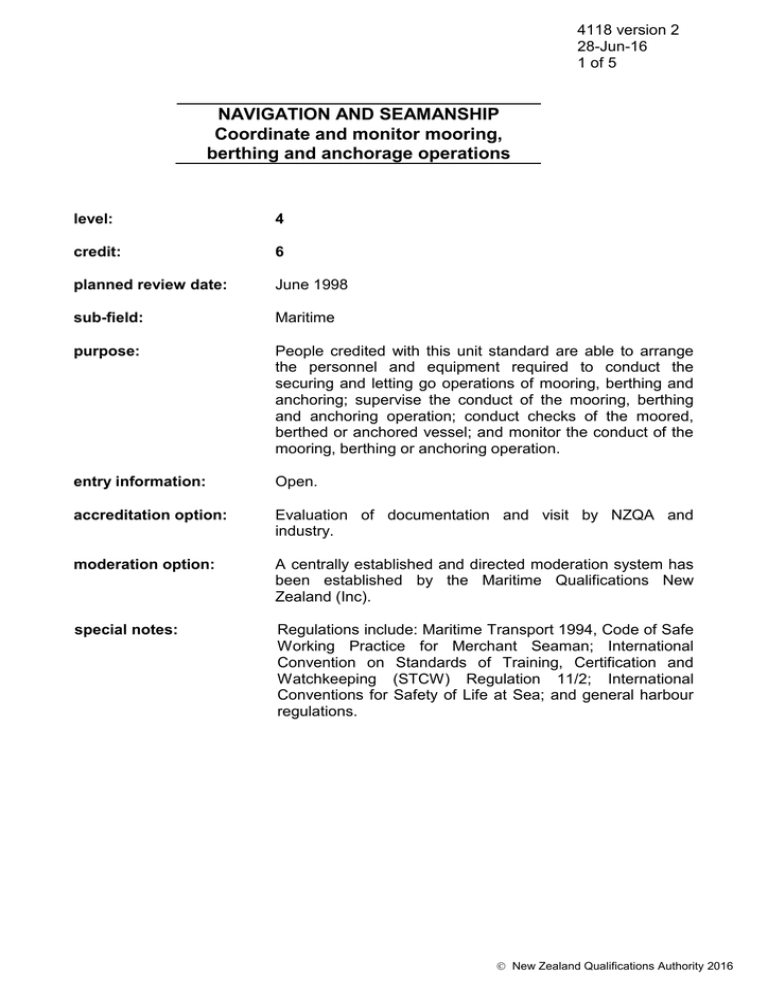

4118 version 2 28-Jun-16 1 of 5 NAVIGATION AND SEAMANSHIP Coordinate and monitor mooring, berthing and anchorage operations level: 4 credit: 6 planned review date: June 1998 sub-field: Maritime purpose: People credited with this unit standard are able to arrange the personnel and equipment required to conduct the securing and letting go operations of mooring, berthing and anchoring; supervise the conduct of the mooring, berthing and anchoring operation; conduct checks of the moored, berthed or anchored vessel; and monitor the conduct of the mooring, berthing or anchoring operation. entry information: Open. accreditation option: Evaluation of documentation and visit by NZQA and industry. moderation option: A centrally established and directed moderation system has been established by the Maritime Qualifications New Zealand (Inc). special notes: Regulations include: Maritime Transport 1994, Code of Safe Working Practice for Merchant Seaman; International Convention on Standards of Training, Certification and Watchkeeping (STCW) Regulation 11/2; International Conventions for Safety of Life at Sea; and general harbour regulations. New Zealand Qualifications Authority 2016 4118 version 2 28-Jun-16 2 of 5 NAVIGATION AND SEAMANSHIP Coordinate and monitor mooring, berthing and anchorage operations Mooring operations include: making fast fore and aft to a fixed terminal or jetty; making fast to a single point mooring, making fast to a conventional buoy mooring; preparing mooring area for operations; making fast and letting go tugs; adjusting moorings during port stay; securing mooring area on departure; and rigging gangways, accommodation ladders and pilot ladders. Operations include: securing, letting go and adjusting the ship’s position alongside; carrying out routine checks of the ship’s safety and integrity when moored; securing the ship for sea; securing and letting go the ship at anchor; hanging off the ship’s anchor; and tug and tug line operations. Mooring equipment includes: fibre and wire rope moorings; heavy lines and stoppers; tension winches; stand alone winches; capstans; fairleads; windlass; and chain locker. Equipment malfunctions or problems may include:: failure of moorings or equipment, damage to moorings, insufficiency of moorings, poor leads, and inability to maintain the ship’s position. Elements and Performance Criteria element 1 Supervise operations involved with securing, letting go, and adjusting the ship’s position alongside. performance criteria 1.1 The activities of personnel engaged in mooring the ship are co-ordinated and conducted to maintain the operation in accordance with safety rules and regulations. New Zealand Qualifications Authority 2016 4118 version 2 28-Jun-16 3 of 5 NAVIGATION AND SEAMANSHIP Coordinate and monitor mooring, berthing and anchorage operations 1.2 Mooring decks are prepared for mooring operations in accordance with instructions, and mooring equipment is kept free from loose ropes, wires and debris. 1.3 Leads are determined accurately and the tension placed on mooring lines is maintained at a level which reflects the stage and nature of the operation with respect to warping the ship or maintaining position. 1.4 The mooring deck area is secured on completion of operations and is commensurate with projected ship operations or orders provided. 1.5 Equipment malfunctions or problems are evaluated and rectified or communicated clearly and concisely to the bridge to minimise risk to personnel, equipment or the ship. element 2 Supervise operations involved in securing the ship at anchor. performance criteria 2.1 The activities of personnel engaged in anchoring operations are co-ordinated and conducted to maintain the operation in accordance with safety rules and regulations. 2.2 Preparation of the anchor and equipment prior to letting go and the quantity of cable run out or recovery complies with the orders received. 2.3 Control of the cable is maintained within safe operating limits of the equipment during routine operations. Range: operating limits are defined by the equipment manufacturers. 2.4 The operation of windlass and winch machinery conforms with manufacturer’s recommendations and anchoring requirements. 2.5 The area around the windlass and hawse pipes is maintained free from loose ropes, wires and debris throughout the operation. New Zealand Qualifications Authority 2016 4118 version 2 28-Jun-16 4 of 5 NAVIGATION AND SEAMANSHIP Coordinate and monitor mooring, berthing and anchorage operations element 3 Monitor mooring and anchoring operations. Range: under the direction of the ship’s master. performance criteria 3.1 Operations are monitored and completed in accordance with company operating procedures and established safety rules and regulations, and where variance in operations is discovered, prompt action is taken to rectify the situation. 3.2 Reports on incidents and equipment malfunctions are evaluated and action is taken to maximise the security of the ship and minimise the risk to personnel and equipment. 3.3 The ship’s master is provided with feedback on the mooring and anchoring operation, its effectiveness, problems, unresolved issues, and progress. 3.4 Incident reports and documentation relating to the mooring operation are completed and, where required, are evaluated promptly and action is taken to maximise the mooring security of the ship. 3.5 Communication is maintained throughout the operation with the supervising officer on the bridge. New Zealand Qualifications Authority 2016 4118 version 2 28-Jun-16 5 of 5 NAVIGATION AND SEAMANSHIP Coordinate and monitor mooring, berthing and anchorage operations Comments to: Maritime Qualifications New Zealand (Inc) Unit Standard Revision PO Box 160 WELLINGTON by June 1998. Please Note: Providers must be accredited by the Qualifications Authority before they can offer programmes of education and training assessed against unit standards. Accredited providers assessing against unit standards must engage with the moderation system that applies to those unit standards. [Please refer to relevant Plan ref: 0054] New Zealand Qualifications Authority 2016