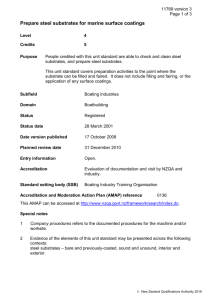

METAL SURFACE FINISHING Polish welded stainless steel fabrications

advertisement

16961 version 2 28-Jun-16 1 of 4 METAL SURFACE FINISHING Polish welded stainless steel fabrications level: 3 credit: 10 planned review date: December 2002 sub-field: Mechanical Engineering purpose: People credited with this unit standard are, on welded stainless steel fabrications, able to: prepare for polishing operations; perform polishing operations; and control polishing quality. entry information: Recommended: prior credit for Unit 2396, Select, use, and maintain portable hand held engineering power tools, Unit 9184, Erect non-notifiable prefabricated scaffolding, and Unit 12299, Shift loads in the performance of machinery and equipment installation and maintenance, or demonstrate equivalent knowledge and skills accreditation option: Evaluation of documentation and visit by NZQA. moderation option: A national moderation system of regional panels and assessor networks has been established by Competenz. special notes: 1 This unit standard covers the skills and knowledge required to grind and polish welded seams to specified surface roughness values as required on stainless steel equipment fabricated for industries such as food processing, and pharmaceutical. New Zealand Qualifications Authority 2016 16961 version 2 28-Jun-16 2 of 4 METAL SURFACE FINISHING Polish welded stainless steel fabrications 2 Worksite procedure refers to the documented procedures for safety and polishing for a worksite. Elements and Performance Criteria element 1 Prepare for polishing operations on welded stainless steel fabrications. performance criteria 1.1 A safe worksite is assured by identifying potential hazards and following safety procedures in accordance with worksite safety policy. Range: potential hazards may include but are not limited to - risk of electrocution, risk of fire or explosion, inadequate ventilation, confined space, chemical, working at heights. 1.2 The polishing equipment selected is in accordance with that specified in the worksite procedure. 1.3 The polishing consumables selected are in accordance with those specified in the worksite procedure. 1.4 The surface to be polished is prepared in accordance with the worksite procedure. Range: preparation may include but is not limited to - cleaning, pickling and passivating, protecting adjacent areas with tape. New Zealand Qualifications Authority 2016 16961 version 2 28-Jun-16 3 of 4 METAL SURFACE FINISHING Polish welded stainless steel fabrications element 2 Perform polishing operations on welded stainless steel fabrications. performance criteria 2.1 Polishing equipment and consumables are used in accordance with the worksite procedure. Range: 2.2 Surface is checked at regular intervals during polishing operations to identify any imperfections that may need rework. Range: 2.3 equipment may include but is not limited to - grinding wheels and discs, wire brushes, sanding discs and belts, mops, buffs; consumables may include but are not limited to - soaps, lubricants. rework includes but is not limited to - spot grinding, rewelding, planishing. Rework is undertaken, or imperfections reported, in accordance with worksite procedure. element 3 Control polishing quality on welded stainless steel fabrications. performance criteria 3.1 A clean surface is obtained in accordance with worksite procedure. New Zealand Qualifications Authority 2016 16961 version 2 28-Jun-16 4 of 4 METAL SURFACE FINISHING Polish welded stainless steel fabrications 3.2 Inspection verifies that the polished surface is in accordance with job specification. Range: 3.3 inspection may include but is not limited to - visual examination, surface method such as penetrant inspection, surface roughness measurement. The polished finish is protected from potential damage in accordance with worksite procedure. Comments to: Competenz Unit Standard Revision PO Box 160 WELLINGTON by December 2002. Please Note: Providers must be accredited by the Qualifications Authority before they can offer programmes of education and training assessed against unit standards. Accredited providers assessing against unit standards must engage with the moderation system that applies to those unit standards. [Please refer to relevant Plan ref: 0013] New Zealand Qualifications Authority 2016