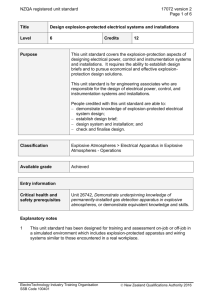

NZQA registered unit standard 26740 version 1 Page 1 of 8

advertisement

NZQA registered unit standard 26740 version 1 Page 1 of 8 Title Demonstrate and apply intermediate underpinning knowledge of electrical apparatus in explosive atmospheres Level 4 Purpose Credits 5 This unit standard covers the essential underpinning knowledge for people working with or intending to work with electrical apparatus in explosive atmospheres. People credited with this unit standard are able to demonstrate: knowledge of hazardous areas installation and maintenance preparation techniques; knowledge of the relationship between explosion-protected apparatus, certification documentation, and required apparatus installation locations for installation as given in specifications and layout drawings and/or written instructions; knowledge of installation Standards and requirements applicable to explosive atmospheres; knowledge of maintenance procedures required in hazardous areas that ensure the integrity of the explosionprotection technique; knowledge of cable termination types suitable for use in hazardous areas; cable terminating methods suitable for use with various protection techniques in hazardous areas environments; knowledge of documents that show the classification of a hazardous area; knowledge of selection and checking of apparatus, wiring, and accessories suitable for use in explosive atmospheres; knowledge of cables and cable selection suitable for use in explosive atmospheres; knowledge of hazardous areas installation design documentation; and knowledge of common and specific hazardous areas for which classification examples are given in Standards. Classification Explosive Atmospheres > Electrical Apparatus in Explosive Atmospheres - Operations Available grade Achieved ElectroTechnology Industry Training Organisation SSB Code 100401 New Zealand Qualifications Authority 2016 NZQA registered unit standard 26740 version 1 Page 2 of 8 Entry information Critical health and safety prerequisites Unit 26739, Demonstrate introductory underpinning knowledge of electrical apparatus in explosive atmospheres, or demonstrate equivalent knowledge and skills. Explanatory notes 1 This unit standard has been designed for training and assessment off-job. 2 References AS/NZS 1768:2007, Lightning protection; AS/NZS 3000:2007, Electrical installations (known as the Australian/New Zealand Wiring Rules); AS/NZS 4761.1:2008, Competencies for working with electrical equipment for hazardous areas (EEHA) Part 1 – Competency standards; AS/NZS 4761.2:2008, Competencies for working with electrical equipment for hazardous areas (EEHA) Part 2 – Guide to assessing competency; AS/NZS 60079.0:2008, Explosive atmospheres – Equipment – General requirements; AS/NZS 60079.10.1:2009, Explosive atmospheres – Classification of areas – Explosive gas atmospheres; AS/NZS 60079.14:2009, Explosive atmospheres – Electrical installations design, selection and erection; AS/NZS 60079.17:2009, Explosive atmospheres – Electrical installations inspection and maintenance; AS/NZS 60079.29.2:2008, Explosive atmospheres – Gas detectors – Selection, installation, use and maintenance of detectors for flammable gases and oxygen; AS/NZS 61241.0:2005, Electrical apparatus for use in the presence of combustible dust – General requirements; AS/NZS 61241.2.1:2000, Electrical apparatus for use in the presence of combustible dust – Test methods – Methods for determining the minimum ignition temperature of dust; AS/NZS 61241.10:2005, Electrical apparatus for use in the presence of combustible dust – Classification of areas where combustible dusts are or may be present; AS/NZS 61241.14:2005, Electrical apparatus for use in the presence of combustible dust – Selection and installation; Electricity Act 1992; Electricity (Safety) Regulations 2010; Hazardous Substances and New Organisms Act 1996; Health and Safety in Employment Act 1992, and associated regulations; and their subsequent amendments and replacements. 3 Definitions Certification documentation – document(s) that assure(s) the conformity of a product, process, system, person, or organisation with specified requirements. Explosion-protection techniques – techniques applied to the design of electrical apparatus, components, and systems to prevent the electrical energy from becoming an ignition source in the presence of flammable vapours and gases or combustible dusts in explosive atmospheres. See explosion-protected apparatus. ElectroTechnology Industry Training Organisation SSB Code 100401 New Zealand Qualifications Authority 2016 NZQA registered unit standard 26740 version 1 Page 3 of 8 Explosion-protected apparatus – electrical apparatus to which specific measures are applied to avoid ignition of a surrounding explosive atmosphere. Such apparatus employs one or more of the following explosion-protection techniques: For gas and vapour atmospheres Ex d – flameproof; Ex e – increased safety; Ex i – intrinsic safety; with levels of protection Ex ia, Ex ib and Ex ic; Ex n – non-sparking; For dusts Ex iD – intrinsic safety (dusts); Ex tD – enclosed; Others, less common Ex p – pressurisation; Ex pD (dust); Ex m – encapsulation, with levels of protection Ex ma, Ex mb, Ex mc (gases and vapours), and Ex mD (dusts); Ex s – special protection; categorised by Zone of application; e.g. ‘Ex s (Zone 0); Ex o – oil immersion; Ex q – sand filled; Ex v – ventilation. The term equipment includes apparatus, as mentioned in many relevant Standards. Explosive atmosphere – volatile substances mixed with air under atmospheric conditions in the form of gases, vapours, mist, or dust in which, after ignition has occurred, combustion spreads to the entire unburned mixture. Hazardous area – area in which an explosive atmosphere is present or may be expected to be present in quantities such as to require special precautions for the construction, installation, and use of apparatus. Inspection – scrutiny with or without partial dismantling, and if necessary, measurement to reach a conclusion on the condition of the apparatus: there are various types and grades of inspection. SWA – steel-wire armoured. Verification dossier – a set of documents showing the complete compliance history of electrical apparatus and installations within hazardous areas, as defined in Standards. 4 Range a Assessment is to take account of variations between the industry sectors and enterprises. For example, apparatus used in underground coal mining will be different in some respects from that used in a petrochemical plant. b All activities and evidence presented for all outcomes and evidence requirements in this unit standard must be in accordance with safe working principles and practices, legislation, policies, procedures, ethical codes and Standards, safe and sound practice, and industry practice; and, where appropriate, manufacturers’ instructions, specifications, and data sheets. Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of hazardous areas installation and maintenance preparation techniques. ElectroTechnology Industry Training Organisation SSB Code 100401 New Zealand Qualifications Authority 2016 NZQA registered unit standard 26740 version 1 Page 4 of 8 Evidence requirements 1.1 Occupational Safety and Health (OSH) procedures to be followed when working in a hazardous area are identified. 1.2 The significance of information provided on the certification documentation and schedules for a given item of explosion-protected apparatus is described. 1.3 The purpose of a verification dossier and the documentation that should be contained within it are described. 1.4 Limitations that apply to the use of tools and testing devices in hazardous areas are explained. Outcome 2 Demonstrate knowledge of the relationship between explosion-protected apparatus, certification documentation, and required apparatus installation locations for installation as given in specifications and layout drawings and/or written instructions. Evidence requirements 2.1 The purpose of markings on the compliance plate and certification documentation for a given item of explosion-protected apparatus is explained. 2.2 Procedures required for matching explosion-protected apparatus with certification documentation and the apparatus specified for an installation are explained. 2.3 The location of the items of explosion-protected apparatus for an installation is identified from specifications and layout drawings and/or instructions. 2.4 Methods of identifying explosion-protected apparatus from the Ex symbol marked on the apparatus, including old apparatus and apparatus certified in other countries, are described. Outcome 3 Demonstrate knowledge of installation Standards and requirements applicable to explosive atmospheres. Evidence requirements 3.1 The use of installation Standards in determining the requirements with which the design of explosion-protected apparatus shall comply is explained. 3.2 Wiring systems permitted and not permitted in or above explosive atmospheres are identified. 3.3 Apparatus types not permitted in or above explosive atmospheres are identified. ElectroTechnology Industry Training Organisation SSB Code 100401 New Zealand Qualifications Authority 2016 NZQA registered unit standard 26740 version 1 Page 5 of 8 3.4 Regulations and Standards to which explosion-protected apparatus and wiring installed in hazardous areas must comply are explained in terms of their application. 3.5 Installation documentation and records including certification are described. Outcome 4 Demonstrate knowledge of maintenance procedures required in hazardous areas that ensure the integrity of the explosion-protection technique. Evidence requirements 4.1 The purpose of a maintenance schedule is described in accordance with relevant Standards. 4.2 The purpose of an inspection schedule is described in accordance with relevant Standards. 4.3 The purpose and extent of the different types and grades of inspections are explained. Range types – initial, periodic, sample; grades – visual, close, detailed. 4.4 The significance of information provided in a maintenance schedule is described. 4.5 The impact of environmental conditions on explosion-protected apparatus is explained. Range 4.6 includes but is not limited to – corrosion, frequency of maintenance. The documentation requirements for recording the maintenance process and results are explained. Outcome 5 Demonstrate knowledge of cable termination types suitable for use in hazardous areas. Evidence requirements 5.1 Explosion-protection features of cable termination devices are described. 5.2 Selection of compliant cable termination devices for given situations and environments is described. Outcome 6 Demonstrate cable terminating methods suitable for use with various explosion-protection techniques in hazardous areas. ElectroTechnology Industry Training Organisation SSB Code 100401 New Zealand Qualifications Authority 2016 NZQA registered unit standard 26740 version 1 Page 6 of 8 Evidence requirements 6.1 Conduit systems including seals to meet hazardous areas requirements are installed. 6.2 Cable with a barrier gland is terminated. 6.3 Multipair, SWA, overall screened, and individual screened cable are terminated into an enclosure. 6.4 Termination and connections of installed cables/circuits are tested. Outcome 7 Demonstrate knowledge of documents that show the classification of a hazardous area. Evidence requirements 7.1 Methods used for classifying hazardous areas are described. 7.2 Delineation of zones, temperature classes, and gas groups of a given hazardous areas from classification documents are interpreted. 7.3 The delineation of zones, temperature classes, and gas groups of a given hazardous area from similar situations previously classified, such as those given in Standards, are interpreted. 7.4 Situations where classification needs to be undertaken and documented by a person competent in non-specific area classification are identified. Outcome 8 Demonstrate knowledge of selection and checking of apparatus, wiring, and accessories suitable for use in explosive atmospheres. Evidence requirements 8.1 Explosion-protected apparatus and accessories to suit the requirements of given hazardous areas are identified. Range 8.2 Wiring systems to suit the requirements of a hazardous area are described. Range 8.3 three of – Zone 0, Zone 1, Zone 2, Zone 20, Zone 21, Zone 22. load and duty requirements, capacitive/inductive effects, inductance/resistance ratio. Earthing and equipotential bonding requirements for a hazardous area installation are explained. ElectroTechnology Industry Training Organisation SSB Code 100401 New Zealand Qualifications Authority 2016 NZQA registered unit standard 26740 version 1 Page 7 of 8 8.4 Procedures used to check the compliance certification of apparatus used in a hazardous area are described. 8.5 Electrical protection systems and devices appropriate to an explosion-protection technique are identified. Range 8.6 may include but is not limited to – overloads, earth fault protection; evidence of two is required. Cable termination devices, including glands, used in explosive atmospheres are described. Outcome 9 Demonstrate knowledge of cables and cable selection suitable for use in explosive atmospheres. Evidence requirements 9.1 Wiring systems and their applications within hazardous areas are described. 9.2 Selection and use of cable glands, reducers, and blanking elements for hazardous areas are described. 9.3 Cables are described in terms of their construction, the materials they are made of, their characteristics, and the environments in which they are to be used. Range includes but is not limited to – fireproof, chemical resistant, impact resistant, flexible, fixed. 9.4 Potential problems resulting from incorrect cable selection are outlined. 9.5 Procedure to make up an SWA cable and gland assembly for a given explosive environment is described. 9.6 An SWA cable and gland assembly are made up in accordance with manufacturers’ specifications. Outcome 10 Demonstrate knowledge of hazardous areas installation design documentation. Evidence requirements 10.1 Items to be included in the design documentation for a hazardous area installation are identified. 10.2 Installation layout, specification, work schedule, and other documentation required for inclusion in a verification dossier is described. 10.3 Essential documentation to be supplied by manufacturers with explosionprotected apparatus and/or accessories is identified. ElectroTechnology Industry Training Organisation SSB Code 100401 New Zealand Qualifications Authority 2016 NZQA registered unit standard 26740 version 1 Page 8 of 8 Outcome 11 Demonstrate knowledge of common and specific hazardous areas for which classification examples are given in Standards. Evidence requirements 11.1 Examples of hazardous areas classifications given in Standards are explained. 11.2 The application of hazardous areas classifications given in Standards to similar situations for the purpose of planning electrical installations in hazardous areas are described. Planned review date 31 December 2016 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 20 May 2011 N/A Consent and Moderation Requirements (CMR) reference 0003 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMRs). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the ElectroTechnology Industry Training Organisation (ETITO) reviewcomments@etito.co.nz if you wish to suggest changes to the content of this unit standard. ElectroTechnology Industry Training Organisation SSB Code 100401 New Zealand Qualifications Authority 2016