12597260_Visuals.ppt (2.217Mb)

Experimental Development and Analysis of a High Force / Volume Extrusion Damper

GW Rodgers, C Denmead, N Leach, JG Chase & John B Mander

‘Energy Dissipation Without Damage’

Problem:

Damage to concrete and yielding of re-bar

Requires expensive repair or retrofit

Solution:

Putty

Does not require expensive repair

Must be small enough to fit where traditional dampers do not!

And deliver forces just as large!

Device fixed to rebar cage at each end and embedded in concrete for containment

Objectives: - To eliminate yielding in the critical reinforcing bars

- To absorb more energy than a ductile concrete system

Other Possible Applications

Seismically Vulnerable Bridge Piers

Direct Placement into Steel Joints

Dissipative rocking with no damage

Steel Beam

Single or double bulge extrusion damper fixed to column

Steel joints

Reinforced concrete joints

Bridge decks

Tuned mass dampers

Base isolation

Gap transmits joint rotation to damper instead of damage

Steel

Beam

Steel

Column

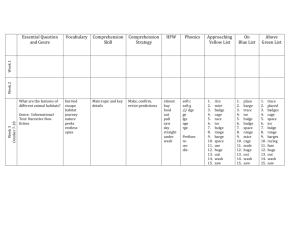

Requirements

High force capacity = High dissipation

Only 3-10 large response cycles per big earthquake

Small device volume

Tight constraints for typical structural connections - Universal column sections nominally 350mm deep – W14 in American Codes

Maximum energy dissipation per cycle

“Square” hysteresis loop

Goal : Dissipate energy in the device every cycle rather than by damage to structural connections

Sinusoidal

Input

Lead

Test Method

• 500kN compression testing device

• Quasi-Static

• DARTEC 10,000kN dynamic test system

Fixed in Place

150

100

50

0

-20

-50

-100

-150

Results without pre-stress

• 40mm bulge

• Quasi-static test

• 100kN peak force, 50kN average

• Not repeatable

• Trailing void formation ~10%

Peak force only in

“new” material

40 mm diameter bulge with un-pre-stressed lead

Device coring trailing void

-10 0 10 20 30

Displacement (mm)

Results with pre-stress

300

200

100

0

-5

-100

-200

-300

200

150

100

-100

-150

-200

50

0

-5

-50

5

5

15

15

25

25

Displacement (mm)

35

35

Displacement (mm)

45

45 55

• Air voids decreased by 3-5x

• ‘Squarer’ hysteresis loops for max energy dissipation

• Repeatable results

55

• Small decrease in force still due to air voids, but much less

• Air voids same ~2-3% volume

• 40mm bulge has longer void as smaller bulge than 50mm as it is about void volume

Experimental Relationships

• Variation in reported and experimental relationships

– linear and polynomial

• Linear relationship in tested region

• Likely the relationship would become exponential

Force/Bulge diameter relationship

Force/Bulge Diameter Relationship

1000

900

800

700

600

500

400

300

200

100

0

30

Friction

35 40 60

Shaft Yield

65 70 45 50 55

Bulge diameter (mm)

Reported relationship

Least square fit

Experimental Relationships

350

300

250

200

150

100

50

0

0

Relationship between ratio of bulge area to cylinder area and Force

0.05

0.1

Exhibits Mohr-Coulomb Behaviour

D

D

D

A shaft

o

A bu lg e

0.15

0.2

0.25

Face Area bulge/Area cylinder

0.3

0.35

0.4

• Ratio makes relationship device independent

• Linear relationship

• Wider variety of devices

• Relationship used to estimate design force

Can be readily used for new device designs

Structural Impact

Spectral Response decreases with increasing damper size

• Reduced magnitude of structural response and damage

• Multiple earthquake suites (3x20=60) of probabilistically scaled earthquake records – near field and far field ground motions

El Centro Response Spectra

Reduction in response with increasing damper size

Reduction in response with increasing damper size

Structural Impact

Reduction Factors

• Design spectra divided by the spectra with added extrusion damping

• Indicates the magnitude of the achieved reduction in response

Reduction factors increase with increasing damper size

Structural Design Impact

Multiple Equation Regression Analysis

• Spl it the spectra into 3 regions based upon existing bifurcation points

• Use linear regression analysis and linear interpolation

• Obtain equations to estimate damping reduction factors

• Enable use in structural design analyses

Conclusions

Importance of pre-stress in repeatable device behaviour and maximum energy dissipation identified

Full-scale 300kN+ prototype created and tested

Final device design underwent proof-of-concept testing over entire speed range

Analytical design space characterised and device independent

Results not same compared to studies reported in the literature

Comprehensive theoretical simulation of device placement in a structure shows significant impact on response

Future work requires some minor modifications but the concept is proven for multiple devices