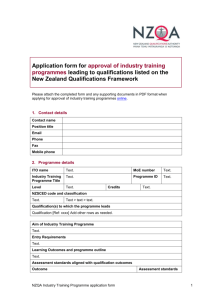

Qualification details New Zealand Certificate in Industrial Textile Fabrication (Level 3)

advertisement

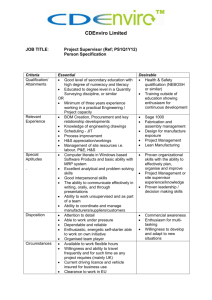

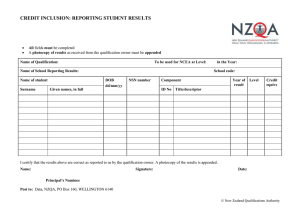

Qualification details Title New Zealand Certificate in Industrial Textile Fabrication (Level 3) Version 1 Qualification type Certificate Level 3 Credits 120 NZSCED 030105 Engineering and Related Technologies > Manufacturing, Engineering and Technology > Textile Making DAS classification 437 Manufacturing > Industrial Textile Fabrication Qualification developer NZ Motor Industry Training Organisation Next review December 2019 Approval date January 2015 Strategic purpose statement The purpose of this qualification is to provide the industrial textile fabrication industry with people who are able to accurately fabricate a variety of industrial textile products according to job and organisational requirements. Graduates will benefit by having a qualification which recognises skills and knowledge in industrial textile fabrication craft or manufacture to enable improved job performance, and further training or study within this industry. The industrial textile fabrication industry will benefit by having people with recognised skills and knowledge to competently fabricate industrial textile products under limited supervision. This qualification is targeted at people entering the industrial textile fabrication industry and will also provide a credential for those already working in the industry. It is intended to be attainable in a variety of industrial textile fabrication industry contexts. Graduates will be familiar with industrial textile fabrication processes and have the necessary skills and knowledge to work safely within the industrial textile fabrication environment. Outcome Statement Graduate profile Qualification Reference 2543 © New Zealand Qualifications Authority 2015 Graduates of this qualification will be able to: - Understand and comply with organisational health and safety Standard Operating Procedures (SOPs). Contribute to, and communicate in, a work team in the industrial textiles trade environment. Prepare, adjust and maintain textile fabrication machines and ancillary equipment. Apply basic knowledge of materials and hardware used in industrial textile fabrication. Page 1 of 7 - Education pathway Apply knowledge of industrial textile fabrication techniques to create fabricated textile items as directed. This qualification is the first step in the New Zealand industrial textiles qualification pathway and may lead to: New Zealand Certificate in Industrial Textile Fabrication (Level 4) [Ref: 2544]. Employment pathway Holders of this qualification will have the skills and knowledge to work as trade assistants in the sub sector of the industrial textile fabrication field in which they were trained. For example, Assistant Sail Maker, Assistant Canvas Fabrication Technician, Assistant Motor Trimmer. With some context related workplace training they will also be able to use their skills in other industrial textile fabrication sub sectors. Qualification specifications Qualification award This qualification may be awarded by the NZ Motor Industry Training Organisation (Inc) as the qualification developer, and the industry training organisation arranging training leading to the qualification under section 5 of the Industry Training Act 1992. This qualification may also be awarded by an education organisation accredited under section 250 of the Education Act 1989 to deliver an approved programme leading to this qualification. The formal document certifying the award of this qualification will display the NZQF logo and may also include the name and/or logo of the awarding education organisation. Evidence requirements for assuring consistency TEOs will supply evidence that demonstrates how the graduate outcomes are being met. Evidence should include: - - - - Credit transfer and recognition of prior learning arrangements Qualification Reference 2543 © New Zealand Qualifications Authority 2015 surveys of graduates and employers which determine how well graduates are meeting the graduate outcomes in the workplace reports from consultation with major industry associations to ensure graduates are meeting their members’ needs demonstration of effective processes to identify changes in industry practice and training requirements. For example, meeting minutes from industry advisory groups any other evidence, including workplace evidence, that shows how the graduate outcomes are being met. Education organisations must have policies and procedures in place for managing credit transfer, and assessing recognition of prior learning and recognition of current competency. These policies and procedures, and Page 2 of 7 information about associated fees, must be available to the candidate prior to enrolment. To facilitate credit transfer, education organisations must clearly demonstrate the equivalency or comparability between each of the outcomes in the graduate profile, and the assessment components of their programmes. Minimum standard of achievement and standards for grade endorsements The minimum standard of achievement required for the award of the qualification will be successful completion of an NZQA approved programme leading to achievement of the outcomes in the graduate profile. Entry requirements (including prerequisites to meet regulatory body or legislative requirements) N/A Qualification conditions Overarching conditions relating to the qualification Conditions for programme structure Assessment for outcomes of the qualification is generally expected to be based on workplace portfolio evidence – much of which is expected to be naturally occurring. Conditions for programme context It is generally expected that programmes leading to the qualification will be done in the workplace. Competence may be demonstrated in different sub sector contexts depending on the workplace. Examples include but are not limited to: general industrial textile fabrication, specialised industrial textile fabrication, sailmaking, inflatable boat construction, vehicle or boat trimming, tent and marquee construction. The qualification is intended to cater to both computer aided manufacturing and custom hand-built contexts. Competence is expected to be demonstrated with the candidate under supervision. Other conditions All outcomes must be met with consideration of legislative and organisational Standard Operating Procedures(SOPs). Appropriate health and safety procedures must be followed in accordance with workplace and legislative requirements for all tasks leading to assessment of this standard. Personal protective equipment (PPE) must be used throughout operations in accordance with company procedures and manufacturer’s instructions. The current version of the following documents must be complied with: Health and Safety in Employment Act 1992; Health and Safety in Employment Regulations 1995; Qualification Reference 2543 © New Zealand Qualifications Authority 2015 Page 3 of 7 TEOs arranging training or delivering programmes towards this qualification must ensure that the training arranged and programmes of learning delivered, are kept up-to-date with regard to amendments to, and replacements of relevant legislation, regulations and Australia/New Zealand Standards (AS/NZS). Current standards can be accessed at http://standards.co.nz. Current legislation and regulations can be accessed at http://legislation.govt.nz. Specific conditions relating to the Graduate profile Qualification outcomes Conditions Mandatory or Optional 1 Understand and comply with organisational health and safety Standard Operating Procedures (SOPs) Programmes will include the following topics: Mandatory safe working practices (10 credits) employee responsibilities under the HSE Act manual handling hazards toxicity of materials fumes noise dust PPE housekeeping hygiene storage and handling of chemicals used in industrial textile fabrication Programmes will include the following unit standards: Mandatory 497 17593 Completion of the following unit standards may be used to prove competence: Optional 23514 2 Contribute to, and communicate in, a work team in the industrial textiles trade environment Qualification Reference 2543 © New Zealand Qualifications Authority 2015 Programmes will include the following topics: communication of workplace Page 4 of 7 (5 credits) information personal responsibilities in the workplace Completion of the following unit standards may be used to prove competence: Optional 9681 3 Prepare, adjust and maintain textile fabrication machines and ancillary equipment Programmes will include the following topics: high frequency welding (20 credits) hot knives powered cutting equipment bandsaws knives ladders electrical equipment compressed air sewing machines hand tools power tools workshop equipment Programmes may include: high freq welders hot air welders wedge welders ultrasonic welders Completion of the following unit standards may be used to prove competence: Mandatory Optional Optional For mandatory conditions: 23479 23480 23489 23490 For optional conditions: 23500 23501 23502 Qualification Reference 2543 © New Zealand Qualifications Authority 2015 Page 5 of 7 4 Apply basic knowledge of materials and hardware used in industrial textile fabrication Programmes will include the following topics: material type (10 credits) finishes – coated, laminated etc. construction type – woven, knitted, braided, unsupported, coated mechanical properties – tensile, tear, fire resistance, mildew, colourant, acoustic, chemical resistance, UV resistance, stability Hardware types, uses and purpose Completion of the following unit standards may be used to prove competence. Mandatory Optional 23483 23495 5 Apply knowledge of industrial textile fabrication techniques to create fabricated textile items as directed (75 credits) Programmes will include the following topics: basic drawings, sketches, CAD, scale drawings, plans production templates and patterns typical shop floor specifications including materials, quantities, and labour breakdown. accurate measurement, marking and cutting cutting material economically and efficiently checks/quality procedures Standard Operating Procedures (SOPs) use of fabricating machines, tools and equipment packing, presenting and labelling may include forklift operation. Completion of the following unit standards may be used to prove competence. Mandatory Optional 1320 Qualification Reference 2543 © New Zealand Qualifications Authority 2015 Page 6 of 7 5022 10851 14145 23481 23482 23484 23485 23486 23487 23488 23491 23492 23493 23494 23496 23498 23499 23504 23505 23506 23513 Transition information Replacement information This qualification replaced the National Certificate in Industrial Textile Fabrication (Level 3) with strands in Canvas Fabrication; Sailmaking; and Vehicle Trimming and Upholstery [Ref: 1340]. The last date for entry into programmes leading to the replaced qualification [Ref: 1340] is 31 December 2015. The last date for completion of that qualification is 31 December 2018, at which time it will be designated as discontinued. Existing candidates may either complete the replaced qualification or transfer to the New Zealand Certificate in Industrial Textile Fabrication (Level 3) [Ref: 2543]. Qualification Reference 2543 © New Zealand Qualifications Authority 2015 Page 7 of 7