Download the Final Presentation

advertisement

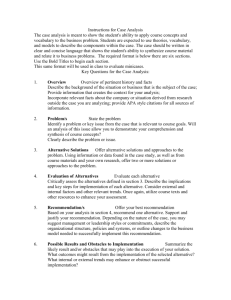

LA Fitness, West Oaks Houston, Texas David Melfi Mechanical Option The Pennsylvania State University Department of Architectural Engineering Senior Thesis Spring 2006 Presentation Outline • • • • • • • • Building Description Goals & Metrics Design Parameters Air Side Alternatives Hot Water Alternatives Discussion of Original Design Desiccant Dehumidification Recommendation Building Description Building Information • • • • • 45,000 ft2 Exercise Facility Houston, TX Construction Cost of Building: Started: 5/9/05 $4.5 Million Finished: 12/09/05 Primary Project Teams • • • • • • • • Owner: General Contractor: Construction Manager: Architects: MEP Engineers Structural Engineers: Civil Engineers: Interior Designers: LA Fitness International, LLC Ridgemont Construction LA Fitness International, LLC Heights Venture Architects, LLP Advanced Technologies, Inc. BGA Engineers Cobb Fendley & Associcates Senninger Walker Architects Presentation Outline • • • • • • • Building Description Goals & Metrics Design Parameters Air Side Alternatives Hot Water Alternatives Discussion of Original Design Desiccant Dehumidification Recommendation Goals & Metrics Design Goals • • • • Energy Reduction Compared to Original Design Lower Environmental Impact Economic Feasibility Gain Practical Experience Designing and Integrating Mechanical Systems Metrics • Annual Energy Consumption • Emissions • Economics Analysis Presentation Outline • • • • • • Building Description Goals & Metrics Design Parameters Air Side Alternatives Hot Water Alternatives Discussion of Original Design Desiccant Dehumidification Recommendation Design Parameters • Ventilation Requirements • Standard 62.1-2004 Reevaluation • • • • • Cooling & Heating Loads Lighting Loads Building Envelope Humidity Control Critical Zones Design Parameters Ventilation ASHRAE Standard 62.1-2004 Requirements: Voz Vot Actual Design OA Total Airflow Design %OA 62.1n %OA RTU-1 154 154 500 5000 10.0 3.1 RTU-2 950 1188 700 5000 14.0 23.8 RTU-3 3620 3620 3500 10500 33.3 34.5 RTU-4 807 807 3350 8300 40.4 9.7 RTU-5 629 629 750 7500 10.0 8.4 RTU-6 1368 1368 750 6000 12.5 22.8 RTU-7 1419 1419 1000 10000 10.0 14.2 RTU-8 651 651 500 4000 12.5 16.3 RTU-9 2420 2420 1675 6600 25.4 36.7 RTU-10 2420 2420 1675 6600 25.4 36.7 RTU-11 944 1049 750 5500 13.6 19.1 RTU-12 524.5 524.5 500 3500 14.3 15.0 RTU-13 1380 1380 750 5900 12.7 23.4 Entire Building 17286 17628 16400 84400 19.4 20.9 Design Parameters Critical Zones • Indoor Pool & Locker Room Spaces • Relatively Negative Pressure • 4-6 Air Changes/Hour • 800F & 55% Relative Humidity • Pool Water Temperature: 820F • Latent Load From Pool 102,950 Btu/hr Presentation Outline • • • • • Building Description Goals & Metrics Design Parameters Air Side Alternatives Hot Water Alternatives Discussion of Original Design Desiccant Dehumidification Recommendation Air Side Alternatives Original Design • • • • • Cooling Loads Met by 13 Packaged Rooftop Units Constant Volume Primarily Single Zone Economic Advantage Over Other Equipment OA Rebalance and Redistribution Is Necessary End-Use Lighting HVAC Energy Consumption 368,172 4,285 Unit of Energy kWh MMBtu Enery First Cost Cost/Unit Cost/Year of System $0.078 $28,717 N/A $14.660 $62,818 $419,000 Building Emissions lbm Fuel Coal Natural Gas Totals Particulates/yr 166 0 166 SO2/yr NOx/yr CO2/yr 1,929 1,119 324,728 8 1,469 774,865 1,937 2,589 1,099,593 Air Side Alternatives Hydronic System – Water Cooled Chiller • • • • • Screw Compressor 200 ton Chiller Performing at 0.66 kW/ton Cooling Tower Necessary 4 AHU Needed to Condition the Air Higher Associated Maintenance Cost/Year End-Use HVAC Original Design Differential Energy Consumption 843,084.0 4,285.0 -412,777.7 Fuel Coal Natural Gas Totals Differential Unit of Energy kWh MMBtu kWh Enery First Cost of Cost/Unit Cost/Year System $0.078 $65,761 $433,345 $14.660 $62,818 $419,000 N/A $2,942 $14,345 Building Emissions lbm Particulates/yr SO2/yr NOx/yr CO2/yr 546 6,347 3,682 1,068,328 0 0 0 0 546 6,347 3,682 1,068,328 380 4,410 1,094 -31,267 Air Side Alternatives Hydronic System – Air Cooled Chiller • • • • • Screw Compressor 200 ton Chiller performing at 1.22 kW/ton Less Maintenance Cost Compared to WC Chiller Less Efficient Performance Relatively Good Part Load Performance Energy End-Use Consumption HVAC 1,018,379.0 Original Design 4,285.0 Differential -237,482.7 Fuel Coal Natural Gas Totals Differential Unit of Enery First Cost of Energy Cost/Unit Cost/Year System kWh $0.078 $79,434 $427,990 MMBtu $14.660 $62,818 $419,000 kWh NA $16,615 $8,990 Building Emissions lbm Particulates/yr SO2/yr NOx/yr CO2/yr 625 7,266 4,215 1,222,938 0 0 0 0 625 7,266 4,215 1,222,938 459 5,329 1,627 123,344 Air Side Alternatives Discussion of Energy Sources • Hydronic Systems • Lower Annual Energy Consumption? No • Lower Annual Energy Costs? No Presentation Outline • • • • Building Description Goals & Metrics Design Parameters Air Side Alternatives Hot Water Alternatives Discussion of Original Design Desiccant Dehumidification Recommendation Hot Water Alternatives Original Water Heating • • • • Three Natural Gas Fired Water Heaters 1200F Water 300 MBH 100 gal of Storage Each Solar Water Heating • Three Types Commercially Available • Unglazed Flat Plate Collector • Glazed Flat Plate Collector • Evacuated Tube Collector • Model Established Using RETScreen Solar Water Heating Program Hot Water Alternatives Solar Water Heating • Results of Analysis: Technology Unglazed Flat Plate Collector Glazed Flat Plate Collector Evacuated Tube Collector • • • • Model Heliodyne Mojave 410 Heliodyne Gobi 408 Thermomax Mazdon 20 Energy Delivered % Demand Payback Per Year (MMBtu) Per Year First Cost Period (Years) 18.94 29.9% $4,752 8 33.94 53.6% $5,589 5.3 43.26 68.3% $16,999 11.6 Use Glazed Flat Plate Collector In Final Design Issues of Solar Reliability Use Existing Water Heaters as Storage Tanks Structural Analysis Necessary for Flat Roof Presentation Outline • • • Building Description Goals & Metrics Design Parameters Air Side Alternatives Hot Water Alternatives Discussion of Original Design Desiccant Dehumidification Recommendation Discussion of Original Design Original Rooftop Unit Design • Pros: • Lowest annual primary energy • Lowest emissions • Lowest first cost • Cons: • • • • High load on DX coil RTU-1 & RTU-2 lose humidity control Wasteful to cool & dehumidify air reheat the air cfm/ton limitations Discussion of Original Design • Original Rooftop Unit Design • RTU-1 & RTU-2 Discussion of Original Design • Original Rooftop Unit Design • Reheat & Humidity Sensor Option Discussion of Original Design Is there a better way to meet the air side loads while satisfying the design criteria? Up until this point in the analysis, the focus of study was to find a completely new base system that could better meet the airside loads. Paradigm shift: Instead of finding better alternative from scratch the question became: How can the existing “good enough” equipment be modified to have better performance for this site? Presentation Outline • • Building Description Goals & Metrics Design Parameters Air Side Alternatives Hot Water Alternatives Discussion of Original Design Desiccant Dehumidification Recommendation Desiccant Dehumidification • Another means to control humidity • Low surface vapor pressure attracts moisture from air • System can be configured in a rotating “honeycomb” wheel arrangement • Sensible Heat Gain from Process • Active or Passive? • Decision Made to Use Active Desiccant • Sensible Wheel Also Necessary Desiccant Dehumidification Active Desiccant Configuration with Sensible Wheel • Air processed by desiccant leaves very hot and dry • Sensible wheel used to restore a hot, dry temperature • Air heater used to reactivate desiccant for further use • Result of process: significant reduction of latent load Desiccant Dehumidification • Psychrometric Analysis of Wheels Presentation Outline • Building Description Goals & Metrics Design Parameters Air Side Alternatives Hot Water Alternatives Discussion of Original Design Desiccant Dehumidification Recommendation Recommendation Initial idea to modify each unit: • Requires 26 wheels for the 13 units • This idea was too expensive and labor intensive Rather: • Use 1 central dehumidification station to handle all of the OA for the building • Duct the OA from this central unit to the OA intakes of the 13 originally scheduled units Recommendation Recommendation Economic Analysis Energy Consumed/Year Includes New System Components: • Motor energy for wheels • Fan energy Energy End-Use Consumption HVAC 3,190.4 Original Design 4,285.0 Differential -1,094.6 Unit of Enery First Cost of Energy Cost/Unit Cost/Year System MMBtu $14.66 $46,771 $563,662 MMBtu $14.66 $62,818 $419,000 MMBtu NA ($16,047) $144,662 Payback Period Analysis • Conservative Payback Period: 11 Years • Interest Used: 6% • Natural Gas Escalation Rate: 3% • Modified Payback Period: 8.5 Years • Interest Used: 6% • Natural Gas Escalation Rate: 8% Many Thanks To... • Advanced Technologies, Inc • Penn State AE Mechanical Faculty • Dr. James D. Freihaut • Mike Prinkey • Tony Daniels • Karen Schulte • My Family • Friends and Colleagues Questions Integration of Design • The entire building requires 17,630 cfm of OA to meet the corrected Standard 62.1 requirements • Using an Active Desiccant Configuration, 6000 cfm of counterflow air is necessary • EF-5 from the original design was a perfect fit (6,300 cfm) • This exhaust air stream is centrally located near 7 of the 13 rooftop units Energy Rates • Energy Rates Natural Gas Rates • May 2005 Texas Commercial Rate: • Dec 2005 Texas Commercial Rate: $8.67/MMBtu $14.68/MMBtu Electric Rates • May 2005 Texas Commercial Rate: • Dec 2005 Texas Commercial Rate: $22.86/MMBtu $23.45/MMBtu