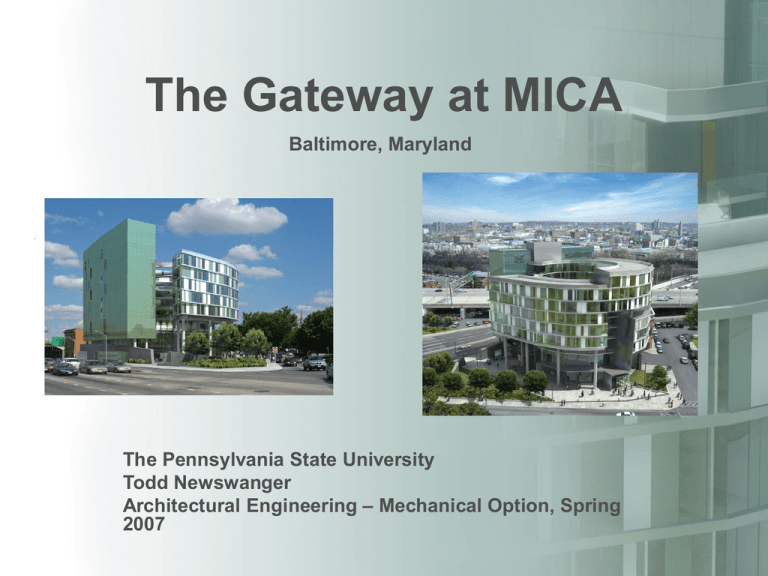

The Gateway at MICA

advertisement

The Gateway at MICA Baltimore, Maryland The Pennsylvania State University Todd Newswanger Architectural Engineering – Mechanical Option, Spring 2007 Presentation Outline • • • • • • • Background Information Existing Conditions Design Objectives Proposed Mechanical System Construction Management Breadth Electrical Breadth Conclusions Building Introduction • • • • New Dormitory for Maryland Institute College of Art (MICA) 120,000 ft2 Approximate Cost $22 Million 10 Story Building Location 1601 Mount Royal Ave. Baltimore, MD Existing Equipment • 4 AHUs – 3 VAV • 2 Serving Floors 1 & 2 • 1 Serving Studio Spaces – 1 CAV • Serves Lobby & Gallery Space • 2 Chillers – 200 Tons Cooling – Air Cooled Screw Chillers • 2 Boilers – Natural Gas Fired – 1632 MBH • FCUs – 51 Units on Floors 3-9 – 2 Pipe System Ground Source Heat Pump • Goal – To save energy and reduce operating costs • • Savings of 25% - 50% on energy consumption Earth provides over 70% of energy needed to heat and cool Closed loop system/ no ventilation needed • – No air pollution minimized impact on environment Ground Source Heat Pump • ASHRAE HVAC Applications Handbook 1999 Methodology – Ground Temperature • 55°F – Thermal Resistances • 0.34 hr·ft·°F/BTU (Annual) • 0.32 hr·ft·°F/BTU (Monthly) • 0.30 hr·ft·°F/BTU (Daily) – Building Loads • Cooling Block Load 3,786,136 BTU/hr • Heating Block Load 2,007,148 BTU/hr • Check For Heating and Cooling Length – Longest Loop Governs Ground Source Heat Pump • Tin At Highest Recommended Value – Cooling 20 – 30°F Higher Than Ground Temp. (85°F) – Heating 10 – 20°F Lower Than Ground Temp. 54 F (35°F) • 42 F Building Side Ground Side ΔT Determined By Heat Balance mb c pg Tb mg c pw Tg • BUILDING LOOP VALVE Loop Fluids – 30% Glycol Solution for Building Loop – Water for Ground Loop COOLING 96 F GROUND LOOP 85 F 150 F BUILDING LOOP 180 F VALVE 63 F HEATING GROUND LOOP COMPRESSOR 35 F Ground Source Heat Pump • Coil Length – Heating 66, 321 ft – Cooling 119,366 ft • Bores – – – – Lot Approx. 34,000 ft2 15 ft Bore Separation 12 x 12 Grid 408 ft Ground Source Heat Pump • Equipment Removed – – – – • Chillers Boilers Pumps $306,200 New Equipment – (13) 25 Ton Units – Installation Costs ($810K) – $5-8K/ Ton, Assumed $6,000 – $1.89 Million • Operating Costs – Design System $304,000 – GSHP System $218,000 • 18.5 Year Payback Combined Heat and Power • • • Goal – Operating Cost Savings Reduce Building’s Environmental Impact Design To Meet Peak Electrical Load Combined Heat and Power • Spark Gap – $0.115/kWh – $1.17/therm – $22.00 • Thermal / Electric Ratio – 454,000 kWh – 249,000 BTU/hr – 1.41 • Electric Load – 2503 kW Combined Heat and Power • Prime Mover Selected – System of 4 Prime Movers – (3) 770 kW, (1) 210 kW • Efficiency of Prime Mover – 770kW - 36% – 210 kW - 33% • Thermal / Electric Ratio – 770 kW - 1.59 – 210 kW - 2.03 Combined Heat and Power • Annual Operating Cost – Designed System - $516,000 – CHP System - $742,000 • Equipment Cost – CHP Equipment Cost - $2.12 Million Heating Load 700 350000 600 300000 500 250000 400 Series1 200000 300 200 100 0 y = 4E-06x 6 - 9E-05x 5 + 0.0097x 4 - 0.6654x 3 + 13.655x 2 - 83.026x + 519.76 R2 = 0.9863 BTU/hr kW Electric Load Poly. (Series1) 150000 100000 50000 Series1 y = 0.038x 6 - 2.6936x 5 + 77.859x 4 1255.7x 3 + 11814x 2 - 46432x + 227261 R2 = 0.9917 0 1 3 5 7 9 11 13 15 17 19 21 23 Hour 1 3 5 7 9 11 13 15 17 19 21 23 Hour Poly. (Series1) Combined Heat and Power • Base Load Design Electric Load – 353 kW Prime Mover – – – – • $390,000 395 kW 35% Efficient 1.51 Thermal / Electric Operating Cost – Prime Mover $353,000 – Electricity $131,000 700 600 500 kW • 400 300 200 100 0 Series1 y = 4E-06x 6 - 9E-05x 5 + 0.0097x 4 - 0.6654x 3 + 13.655x 2 - 83.026x + 519.76 R2 = 0.9863 1 3 5 7 9 11 13 15 17 19 21 23 Hour Poly. (Series1) Combined Heat and Power • CHP System – $484,000 • Designed System – $516,000 12 Year Payback Base Load $700,000.00 $600,000.00 $500,000.00 Cost • $400,000.00 Series1 Series2 $300,000.00 $200,000.00 $100,000.00 $0.00 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 Time (Years) Combined Heat and Power • Emissions SHP – NOx – 19,909 lbm – SOx – 24,638 lbm • Emissions CHP – NOx – 15,257 lbm – SOx – 0 lbm • Difference – NOx – 4,652 lbm – SOx – 24,636 lbm Addition of Equipment Room • Requirements – – – – • 42’x34’ Excavated Poured Concrete Designed To Buildings Specs A Total Cost – MC2 ICE 2000 – $63,265 2 3 3.5 Electrical Distribution • Existing – 208/120V • High Current = Large Wire – Transformers • Studio Tower is Distributed • Residential Tower is Central • Proposed – 480/277V • High Voltage = Lower Current • Low Current = Smaller Wire – Entire Building Distributed – Added Redundancy Electrical Distribution • Distributed Transformers – Distribution Panel • 800 A – Transformers • 7 Transformers • 50 KVA – 112 KVA – Feeders & Grounds • 8 AWG – 2/0 • Central Transformer – Distribution Panel • 1000 A – Central Transformer • 300 KVA – Feeders & Grounds • 6AWG – 500 KCM Electrical Distribution • Designed System Cost – Transformer • $10,000 – Distribution Panel • $25,000 – Wires • $35,000 – $70,000 • Proposed System Cost – Transformers & Breakers • $26,500 – Distribution Panel • $25,000 – Wires • $15,000 – $66,500 • Cost Savings – $3,500 Conclusion Ground Source Heat • Changes To Pump System – Eliminate • Chillers • Boilers • Pumps • Initial Cost – $1.53 Million • Annual Saving – $85,000 • Payback Period – 18.5 Years Conclusion Combined Heat & Power • Changes To System – Added Equipment – Needed Space • Emissions Reduction – NOx – 4,652 lbm – SOx – 24,636 lbm • Initial Cost – $390,000 • Annual Saving – $32,000 • Payback Period – 12 Years Recommendations • Combined Heat & Power – Lower Initial Cost – 12 Year Payback – Reduction of Emissions • Added Equipment Room – Payback - 14 Years • Distributed Electrical System – Added Redundancy – Small Cost Savings Questions