Final Jury PowerPoint

advertisement

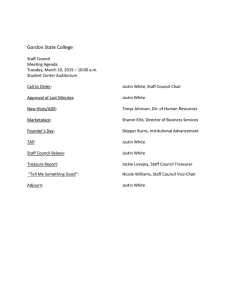

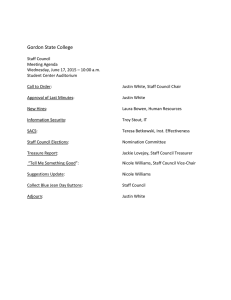

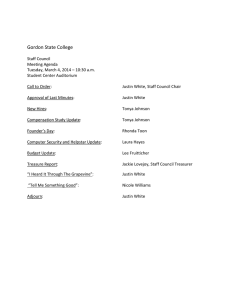

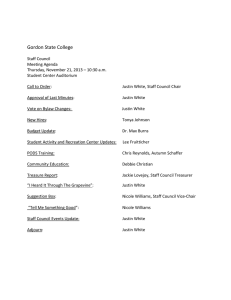

Building Systems Integration - Energy and Cost Analysis The Milton Hershey School New Supply Center Justin Bem AE Senior Thesis – Spring 2007 Mechanical Option Penn State University Project and Building Background Owner - The Milton Hershey School Location – The Milton Hershey School Campus, Hershey, PA Project Size - 110,000 square feet Total Cost - $23,500,000 Design-Bid-Build Contract Construction Dates - July 2006 – July 2007 Justin Bem – Mechanical Option Project and Building Background The Supply Center - General Office and Conference Rooms - Kitchen/Food Preparation Center - Bakery - Clothing Store and Alterations Seamstress - Mail Distribution Center - General Building and MHS Campus Storage Justin Bem – Mechanical Option Existing Conditions Air Side Mechanical System 14 Total Air Handling Units - 10 VAV Units – Serving General Office and Clothing Areas - 4 CAV Units – 100% Outdoor Air Make-Up Units for Kitchen/Bakery - Chilled/Hot Water Coils - Housed in Elevated Mechanical Mezzanine Floor McQuay Custom Air Handling Unit Justin Bem – Mechanical Option Existing Conditions Existing Chiller Plant (2) 270 ton Water Cooled Centrifugal Chillers - Primary-Secondary Pumping - 45°F Chilled Water Serves AHU Coils and Walk-in Freezer Condenser - Electric Driven Vapor Compression Machines - Housed in 1st Floor Mechanical Room Existing Boiler Plant (3) Natural Gas Fired Steam Boilers - Handles All Building HVAC Heating Demands - Meets Domestic Hot Water Heating Demands Justin Bem – Mechanical Option Trane Centrifugal Chiller Existing Conditions Walk-in Freezer Condenser Water Loop Rejected Heat from Condenser to water loop - Removes Additional Heating Load from Kitchen Space - Load Is Met Directly By Chilled Water Plant Via Plate-Frame HX’s - Water Side “Free” Cooling Is Utilized in the Winter for Heat Rejection Justin Bem – Mechanical Option The Redesign Outline Mechanical Redesign Effect on Structural System and Building Construction (3) #10 & 1#10 GD (4) # 350 kcmil (3) #6 1#8 GD (4) #400 kcmil (3) #10 1#10 Justin Bem – Mechanical Option Effect on Electrical System Mechanical System Redesign Objectives Goals - Increase Energy Efficiency - Low Life Cycle Cost - Affordable – (Low First Cost or 2-4 Year Payback Period) Integration of Building Systems with HVAC System - Recover Waste Heat - Perform Multiple Functions from One Fuel Source Justin Bem – Mechanical Option Mechanical System Redesign DOAS/ Water Source Heat Pumps Dedicated Outdoor Air Systems at The Supply Center -10 Existing VAV Air Handling Units Replaced with 2 DOAS Units - Saves in First Cost - Saves in Fan and Chiller Energy Water Source Heat Pumps at The Supply Center - Water Source Loop Integrates Other Building Systems --Condenser Water Loop Heat Recovery - Gives Ability to Heat and Cool Simultaneously Justin Bem – Mechanical Option Mechanical System Redesign DOAS/ Water Source Heat Pumps Justin Bem – Mechanical Option Mechanical System Redesign Condenser Loop Heat Recovery Walk-in Freezers Reject Heat to a Condenser Water Loop - Must Be Cooled for Continues Operation of Freezers - Potential for a Large Amount of Energy Recovery 135gpm Flow Rate 84°F Hot Temperature 65°F Operating Temperature 1282 MBH of Possible Heat Recovery Justin Bem – Mechanical Option Mechanical System Redesign Condenser Loop Heat Recovery Heat Recovery In Water Source Loop - Water Source Heat Pump Loop Requires Winter Time Heat Addition - Operating Temperature of 68°F - Condenser Water Loop Serves as Heat Source Via Heat Exchanger 45°F Chilled Water Condenser Water Loop Return 65°F Walk-In Freezer Condenser Water Loop Supply 84°F Condenser Water Loop Return 78°F Water Source Loop To Heat Source/Sink Justin Bem – Mechanical Option Mechanical System Redesign Condenser Loop Heat Recovery Heat Recovery In Domestic Hot Water Pre-Heat - High Domestic Hot Water Demand at The Supply Center - Condenser Loop Pre-Heats Water to 76-81°F (Saves 35% Heating Energy) 45°F Chilled Water Condenser Water Loop Return 65°F Domestic Hot Water Pre-Heated Condenser Water Loop Return 78-65°F Condenser Water Loop Return 78°F Walk-In Freezer Condenser Water Loop Supply 84°F Water Source Loop To Heat Source/Sink Justin Bem – Mechanical Option Mechanical System Redesign Absorption Chiller-Heater Technology Direct Natural Gas Fired Absorption Chiller-Heaters - Utilizes Natural Gas Service at The Supply Center - Typical Double Effect LiBr/Water Absorption Cycle - Includes Heat Exchanger in High Temperature Generator for Simultaneous Cooling and Hot Water Production (Up to 210°F) Justin Bem – Mechanical Option Mechanical System Redesign Absorption Chiller-Heater Technology Direct Natural Gas Fired Absorption Chiller-Heaters - Simultaneous Heating Comes at the Expense of Cooling Production - Chiller-Heater Must Run at 30% Cooling Capacity Minimum Justin Bem – Mechanical Option Existing System Chiller Plant Load Profile Redesign Plant Load Profile 300 250 Plant Load (Tons) 200 150 100 50 0 0 4 8 12 Hour Justin Bem – Mechanical Option 16 20 24 Mechanical System Redesign Redesigned Chiller/Boiler Plants Chiller-Heater Selection - Sized to Meet Cooling and HVAC/Domestic Hot Water Needs - (2) 240 ton Chiller-Heaters Used - Meets Cooling Load with Enough Capacity to Produce Hot Water Justin Bem – Mechanical Option Mechanical System Redesign Redesigned Chiller/Boiler Plants Redundancy and Reliability -If one Chiller-Heater Is Off Line, Second Meets Critical Load -- Walk-in Freezer’s Condenser System 106 tons -- All other cooling loads are not critical -Back-up Boiler to Meet Heating Demand -- HVAC and Domestic Hot Water INTEGRATES HEATING, COOLING, CONDENSER WATER, AND DOMESTIC WATER SYSTEMS! Justin Bem – Mechanical Option Mechanical System Redesign Redesigned Chiller/Boiler Plants Justin Bem – Mechanical Option Mechanical System Redesign Life Cycle Cost Analysis Energy Rates Natural Gas $/Therm Winter Spring/Fall Summer 1.13 .85 .50 Electricity Rates $0.06 / kW-hr Justin Bem – Mechanical Option Mechanical System Redesign Life Cycle Cost Analysis Annual Operating Cost Comparison Existing System Cooling Cost HVAC Heating Cost Hot Water Heating Cost Combined Heating and Cooling Cost Air System Fan Cost Pump Cost Cooling Tower Cost Total $67,577 $23,016 $58,371 N/A $21,303 $29,274 $9,920 $209,461 Redesign w/ Chiller-Heater N/A N/A N/A $117,370 $12,318 $20,480 $16,440 $166,608 $42,800 Annual Cost Savings! Justin Bem – Mechanical Option Mechanical System Redesign Life Cycle Cost Analysis Annual Energy Consumption Cooling HVAC Heating Domestic Heating Pumps/Fans/CT Total Difference Justin Bem – Mechanical Option Existing System Redesign System 17,100,000 kbtu 17000000 kbtu 6,260,800 kbtu 1,700,000 kbtu 2,200,000 kbtu 2,800,000 kbtu 27,260,000 kbtu 19,800,000 kbtu 7,460,000 kbtu Mechanical System Redesign Life Cycle Cost Analysis Initial Cost Comparison Equipment (Quantity and Type) Chillers (2 Centrifugal) Chiller-Heaters (2) HVAC Boiler (1 4500 MBH) HW Boiler (2 6500 MBH) Supplemental Boiler (1 9000 MBH) Heat Exchangers (for HW system) DOAS AHUs (2) VAV AHUs (10) Plate-Frame HX VAV Boxes w/reheat Heat Pumps TOTAL Existing System 178,000 21,800 61,000 10,000 309,310 10,000 32,730 $622,840 $60,000 More Expensive Justin Bem – Mechanical Option Redesign Chiller-heater Option 450,000 85,000 47,840 20,000 60,045 $682,885 Mechanical System Redesign Life Cycle Cost Analysis Redesign O&M Costs additional $3,000 more per year 20 Year Life Cycle Cost Comparison, 6% Interest Existing System NPW Initial Cost 20 Yr LCC $2,266,510 $622,840 $2,889,350 Redesign System $1,829,863 $682,885 $2,512,748 $376,600 Savings Over 20 Years! Justin Bem – Mechanical Option Mechanical System Redesign Life Cycle Cost Analysis Mechanical Redesign Conclusions - Integrates Multiple Building Systems - More Expensive Up Front - Cheaper to Operate - Least Expensive 20 Year Life Cycle Cost Payback In Just Under 2 Years! Justin Bem – Mechanical Option Effect on Structural System and Building Construction Justin Bem – Mechanical Option Structural/Construction Breadth AHU Relocation Existing System Creates SpaceininMezzanine MezzanineFloor Floor 14 Total Wasted AHUs housed 10 VAV 4 CAV Redesigned System 6 Total AHUs 2 DOAS 4 CAV Move AHUs to Roof - Creates Structural Work - Potential to Save Initial Cost Justin Bem – Mechanical Option Structural/Construction Breadth AHU Relocation Steel K-Series Joist are Replaced with W-flanged Beams Justin Bem – Mechanical Option Structural/Construction Breadth Mezzanine Floor Cost No Need to Construct Mezzanine Floor Only Held Air Handling Units Justin Bem – Mechanical Option Structural/Construction Breadth Mezzanine Floor Cost Large First Cost Savings for Not Construction Mezzanine Floor Steel Members 1-1/2” Steel Decking 139 C.Y. of 4000psi Concrete TOTAL FLOOR COST Justin Bem – Mechanical Option Total Construction Cost $122,986.1 $19,762.75 $11,709.6 $154,458.45 Effect on Electrical System (3) #10 & 1#10 GD (4) # 350 kcmil (3) #6 1#8 GD (4) #400 kcmil (3) #10 1#10 Justin Bem – Mechanical Option Electrical Breadth Power System Alterations Less Electric Driven Mechanical Equipment - Chillers, 8 AHUs, Boiler Accessories - Changes Load on Distribution Panels - Saves Cost on Feeder and Wire Sizes Justin Bem – Mechanical Option Electrical Breadth Power System Alterations Additional Electrical Cost ADD ON (3) #10 & 1#10 GD (4) # 350 kcmil (3) #6 1#8 GD (4) #400 kcmil (3) #10 1#10 3 sets of (4) #300 kcmil 3#10 & 1#10 GRD 3#12 & 1#12 GRD 3#12 & 1#12 GRD 3#12 & 1#12 GRD Justin Bem – Mechanical Option Cost per 100 LF 229 2650 379 3000 229 9000 229 137 137 137 Length (ft) 20 65 60 65 20 15 30 30 30 30 Total Total Cost $ 45 1722 227 1950 45 1350 68 41 41 41 $5,534 Electrical Breadth Power System Alterations Electrical Cost Savings Electrical Cost Savings $9,189 New Equipment Electrical Cost $5,534 Total Electrical Cost Savings $3,600 Mechanical Redesign Creates Electrical Cost Savings! Justin Bem – Mechanical Option Conclusions and Recommendations Final Cost Analysis Overall Building System Redesign Cost Analysis Existing System Redesign Mechanical 1st Cost $622,840 $682,885 Mezzanine Cost $154,458 N/A Additional Structural Cost N/A $277 Additional Electrical Cost $3,600 N/A $780,898 $683,173 Total 1st Cost Justin Bem – Mechanical Option Conclusions and Recommendations Final Cost Analysis Conclusions Compared to Existing System - Mechanical Redesign Saves Energy and Cost Over 20 Years - Integrates Other Building Systems - Creates Overall First Cost Savings! $ 98,000 Initial Cost Savings $ 42,800 Yearly Cost Savings $ 531,000 Saved Over 20 Years! Redesign Is Beneficial Justin Bem – Mechanical Option Acknowledgments Thank You! AE Department - Advisor Dr. Bahnfleth H.F. Lenz Company - Tom Hovan, P.E. Deckman Company - Scott Adams My Great Friends for Their Support! Justin Bem – Mechanical Option Building Systems Integration The Milton Hershey School Supply Center Questions? Justin Bem – Mechanical Option Mechanical System Redesign Redesigned Chiller/Boiler Plants Plant Load Analysis - Walk-in Freezer’s Heat Rejection Creates 106 ton Base Load - Peak Cooling Load at 390 tons -High Hot Domestic Hot Water Demand -- Excellent Opportunity for Simultaneous Heating and Cooling! Justin Bem – Mechanical Option Mechanical System Redesign Redesigned Chiller/Boiler Plants AHU Outdoor Air Supplied 3 3640 4 5585 5 3000 7 3000 9 1000 10 1125 11 1045 12 1250 13 3000 14 800 Total 23,445 DOAS 1 6176 DOAS 2 3615 Total 9,791 Difference 13,654 Justin Bem – Mechanical Option Existing System Chiller Plant Load Profile Daily Cooling Load Profile 450 400 350 Plant Load (Tons) 300 250 200 150 100 50 0 0 4 8 12 Hour Justin Bem – Mechanical Option 16 20 24 Existing System Chiller Plant Load Profile Redesign Plant Load Profile 300 250 Plant Load (Tons) 200 150 100 50 0 0 4 8 12 Hour Justin Bem – Mechanical Option 16 20 24 New System Chiller Plant Load Profile Peak Plant Load per Month 450 June 400 April July August Sept 350 Peak Plant Load (Tons) 300 May October 250 200 March January February 150 100 50 0 Justin Bem – Mechanical Option Nov Dec AHU Relocation - Beams sized to limit deflection to avoid ponding Δ = 5wl4/(384EI) Δ = L/240 Justin Bem – Mechanical Option Structural/Construction Breadth AHU Relocation Additional Cost of Redesign Is Small! BEAM/JOIST K series Joist LENGTH 37 W – Flange Justin Bem – Mechanical Option 37 AMOUNT 22 22 Difference TOTAL COST $7,577.6 $7,855.1 $277.5