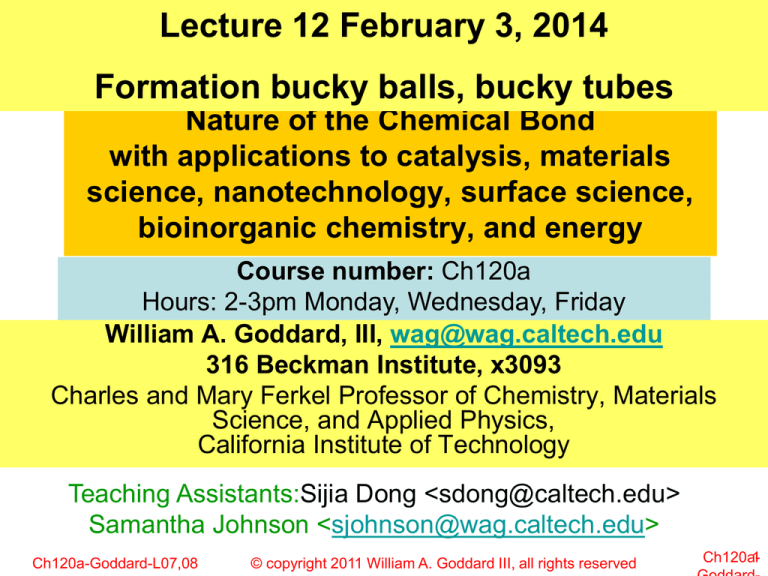

Lecture 12 February 3, 2014

Formation bucky balls, bucky tubes

Nature of the Chemical Bond

with applications to catalysis, materials

science, nanotechnology, surface science,

bioinorganic chemistry, and energy

Course number: Ch120a

Hours: 2-3pm Monday, Wednesday, Friday

William A. Goddard, III, wag@wag.caltech.edu

316 Beckman Institute, x3093

Charles and Mary Ferkel Professor of Chemistry, Materials

Science, and Applied Physics,

California Institute of Technology

Teaching Assistants:Sijia Dong <sdong@caltech.edu>

Samantha Johnson <sjohnson@wag.caltech.edu>

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

Ch120a1

C60 fullerene

No broken bonds

Just ~11.3 kcal/mol

strain at each atom

678 kcal/mol

Compare with 832

kcal/mol for flat sheet

Lower in energy than flat

sheet by 154 kcal/mol!

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

2

Polyyne

chain

precursors

Ch120a-Goddard-L07,08

fullerenes, all even

© copyright 2011 William A. Goddard III, all rights reserved

3

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

4

C540

All fullerens have 12

pentagonal rings

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

5

Mechanism for formation of fullerenes

Heath 1991: Fullerene road. Smaller fullerenes and C3 etc

add on to pentagonal sites to grow C60

Contradicted by He chromatography and high yield of

endohedrals

Smalley 1992: Pentagonal road. Graphtic sheets grow and

curl into fullerenes by incorporating pentagonal C3 etc add

on to pentagonal sites to grow C60

Contradicted by He chromatography

Arc environment: mechanism goes through atomic species

(isotope scrambling)

He chromatography Go through carbon rings and form

fullerenes

Has high temperature gradients

Ring growth road. Jarrold 1993. based on He chromatography

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

6

He chromatography (Jarrold)

Relative abundance of the isomers and

fragments as a function of injection

energy in ion drifting experiments

Conversion of bicyclic ring to fullerene

when heated

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

7

Energies from QM

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

8

Force Field for sp1 and sp2 carbon clusters

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

9

4n vs 4n+2 for Cn Rings

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

10

Population of various ring and fullerene species with Temperature

Based on free energies from QM and FF

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

11

Bring two C30 rings together

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

12

Energetics (eV) for isomerizations converting bicyclic ring to

monocyclic or Jarrold intermediates for n = 30, 40, 50

TS to Bergman cyclization

singlet (leads to Jarrold

ring

mechanism)

2 rings

TS to form tricyclic

E tricyclic

TS convert

C40

C34

E tricyclic

C60

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

13

Energetics (eV) for initial steps of Jarrold

Jarrold

pathway

If get here, then get

fullerene

Modified

Jarrold

Ch120a-Goddard-L07,08

Number pi bonds

© copyright 2011 William A. Goddard III, all rights reserved

14

energetics (eV)

Downhill race from tricyclic to bucky ball

30 eV of energy gain as

form Fullerene

Ch120a-Goddard-L07,08

Number

sp2

centers

© copyright

2011bonded

William A. Goddard

III, all rights reserved

15

Structures in Downhill race from tricyclic to bucky ball

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

16

energetics (eV)

Energy contributions to downhill race to fullerene

Number sp2 bonded centers

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

17

C60 dimer

Prefers packing of 6 fold face

De = 7.2 kcal/mol

Face-face=3.38A

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

18

Crystal structure C60

Expect closest packing: 6 neighbors in plane

3 neighbors above the plane and 3 below

But two ways

ABCABC face centered cubic

ABABAB hexagonal closet packed

Predicted crystal structure 3 months before experiment

Prediction of Fullerene Packing in C60 and C70 Crystals

Y. Guo, N. Karasawa, and W. A. Goddard III

Nature 351, 464 (1991)

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

19

C60 is face centered cubic

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

20

C70 is hexagonal closest packed

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

21

Vapor phase grown Carbon fiber,

R. T. K. Baker and P. S. Harris, in Chemistry and Physics of

Carbon, edited by P. L. Walker, Jr. and A. Thrower (Marcel

Dekker, New York, 1978), Vol. 14, pp. 83–165;

G. G. Tibbetts, Carbon 27, 745–747 (1989);

R. T. K.Baker, Carbon 27, 315–323 (1989).

M. Endo, Chemtech 18, 568–576 (1988).

Formed carbon fiber from 0.1 micron up

Xray showed that graphene planes are

oriented along axis but perpendicular to

the cylindrical normal

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

22

Multiwall nanotubes

"Helical microtubules of graphitic carbon". S. Iijima, Nature

(London) 354, 56–58 (1991).

Ebbesen, T. W.; Ajayan, P. M. (1992). "Large-scale synthesis of

carbon nanotubes". Nature 358: 220–222.

Outer diameter of MW NT

inner diameter of MW NT

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

23

Single wall carbon nanotubes, grown catalytically

S. Iijima and T. Ichihashi, "Single-shell carbon nanotubes of 1-nm

diameter".Nature (London) 363, 603–605 (1993) used Ni

D. S. Bethune, C.-H. Kiang, M. S. de Vries, G. Gorman, R. Savoy, J. Vazquez,

and R. Beyers, "Cobalt-catalyzed growth of carbon nanotubes with singleatomic-layer walls".Nature (London) 363, 605–607 (1993). used Co

Ching-Hwa Kiang grad student with wag on leave at IBM san Jose

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

24

Single wall carbon nanotubes, grown catalytically

S. Iijima and T. Ichihashi, "Single-shell carbon nanotubes of 1-nm

diameter".Nature (London) 363, 603–605 (1993) used Ni

D. S. Bethune, C.-H. Kiang, M. S. de Vries, G. Gorman, R. Savoy, J. Vazquez,

and R. Beyers, "Cobalt-catalyzed growth of carbon nanotubes with singleatomic-layer walls".Nature (London) 363, 605–607 (1993). used Co

Ching-Hwa Kiang grad student with wag on leave at IBM san Jose

Catalytic Synthesis of Single-Layer Carbon Nanotubes with a Wide Range of Diameters C.- H.

Kiang, W. A. Goddard III, R. Beyers, J. R. Salem, D. S. Bethune, J. Phys. Chem. 98, 6612–6618

(1994).

Catalytic Effects on Heavy Metals on the Growth of Carbon Nanotubes and Nanoparticles C.-H.

Kiang, W. A. Goddard III, R. Beyers, J. R. Salem, and D. S. Bethune, J. Phys. Chem. Solids 57, 35

(1995).

Effects of Catalyst Promoters on the Growth of Single-Layer Carbon Nanotubes; C.-H. Kiang, W. A.

Goddard III, R. Beyers, J. R. Salem, and D. S. Bethune, Mat. Res. Soc. Symp. Proc. 359, 69 (1995)

Carbon Nanotubes With Single-Layer Walls," Ching-Hwa Kiang, William A. Goddard III, Robert

Beyers and Donald S. Bethune, " Carbon 33, 903-914 (1995).

"Novel structures from arc-vaporized carbon and metals: Single-layer carbon nanotubes and

metallofullerenes," Kiang, C-H, van Loosdrecht, P.H.M., Beyers, R., Salem, J.R., and Bethune,

D.S., Goddard, W.A. III, Dorn, H.C., Burbank, P., and Stevenson, S., Surf. Rev. Lett. 3, 765-769

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

(1996).

25

Kiang CNT

form 1993

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

26

Kiang CNT form 1993

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

27

Distribution of

diameters for carbon

SWNT, Kiang 1993

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

28

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

29

Examples Single wall carbon nanotubes

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

30

Some bucky tubes

(8,8)

armchair

(14,0)

zig-zag

Ch120a-Goddard-L07,08

(6,10)

chiral

© copyright 2011 William A. Goddard III, all rights reserved

31

Contsruction for (6,10) edge

1

2

3

6

4

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

5

32

13.46A diameter

(10,10) armchair carbon

SWNT

40 atoms/repeat

distance

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

33

(14,0) zig-zag Bucky tube

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

34

Crystal packing

of (10,10) carbon

SWNT

13.5A

Density

SWNT: 1.33 g/cc

Graphite 2.27 g/cc

Ec Young’s modulus

SWNT 640 GPa

Graphite 1093 GPa

16,7A

Heat formation

Graphite 0

C60 11.4

Ch120a-Goddard-L07,08

(10,10)

CNT 2.72

Ea Young’s modulus

SWNT 5.2 GPa

Graphite 4.1 GPa

© copyright 2011 William A. Goddard III, all rights reserved

35

Vibrations in (10,10)

armchair CNT

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

36

Carbon fibers and tubes

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

37

Vibrations in (10,10)

armchair CNT

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

38

Vibrations in (10,10)

armchair CNT

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

39

Mechanism for gas phase CNT

formation

Polyyne Ring Nucleus Growth

Model for Single-Layer Carbon

Nanotubes

C-H. Kiang and W. A. Goddard III

Phys. Rev. Lett. 76, 2515 (1996)

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

40

Mechanism for gas phase CNT formation

A two-stage mechanism of bimetallic catalyzed growth of singlewalled carbon nanotubes Deng WQ, Xu X, Goddard WA

41

Nano Letters

42011

(12):

2331-2335

Ch120a-Goddard-L07,08

© copyright

William

A. Goddard III, all(2004)

rights reserved

But mechanism of gas phase C SWNT, no longer important

The formation of Carbon SWNT by CVD growth on

a metal nanodot on a support is now the preferred

mechanism for forming SWNT

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

42

Mechanisms Proposed for Nanotube Growth

Stepwise Process

Adsorption

Dehydrogenation

Saturation

Diffusion

Nucleation

Growth

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

43

Vapor-Liquid-Solid (Carbon Filament)

Mechanism

• Vapor carbon feed stock adsorbs unto

liquid catalyst particle and dissolves.

Dissolved carbon diffuses to a region of

lower solubility resulting in supersaturation and precipitation of the solid

product.

• Originally developed to explain the growth

of carbon whiskers/filaments.

• Temperature, concentration or free energy

gradient is implicated as the driving force

responsible for diffusion.

Wagner, R. S.; Ellis, W. C. Appl. Phys. Lett. 1964, 4, 89. Bolton, et al. J. Nanosci.

Nanotechnol. 2006, 6, 1211.

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

44

Yarmulke Mechanism

Dai, et al. Chem. Phys. Lett. 1996, 260, 471.

Raty, et al. Phys. Rev. Lett. 2005 95, 096103.

Ch120a-Goddard-L07,08

• Carbon-carbon bonds form

on the surface (either

before or as a result of

super-saturation).

• Diffusion of carbon to

graphene coating can be

an important rate limiting

step.

• Coating of more than a

complete hemisphere

results in poisoning of

catalyst.

• New layers can start

beneath the original layer

after/as it lifts off the

surface resulting in MWNT.

© copyright 2011 William A. Goddard III, all rights reserved

45

Experimental Confirmation of a Yarmulke

Mechanism

Atomic-scale, video-rate environmental transmission

microscopy has been used to monitor the nucleation and

growth of single walled nanotubes.

Hofmann, S. et al. Nano Lett. 2007, 7, 602.

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

46

Role of the Catalyst Particle in Nanotube

Formation

• Size of catalyst particles is related to the

diameter of the nanotubes formed.

• Catalyst nanoparticles are known to deform

(elongate) during nanotube growth.

• Structural properties of select catalyst

surfaces (Ni111, Co111, Fe1-10) exhibit

appropriate symmetry and distances to

overlap with graphene and allow thermally

forbidden C2 addition reaction.

• Graphene is believed to stabilize the high

energy nanoparticle surface. MWNT have

been observed growing out of steps, which

they stabilize.

•

•

•

Ch120a-Goddard-L07,08

Hong, S.; et al. Jpn J. Appl. Phys.

2002, 41, 6142.

Vinciguerra, V.; et al. Nanotechnol.

2003, 14, 655.

Hofmann, S. et al. Nano Lett.

2007, 7, 602

© copyright 2011 William A. Goddard III, all rights reserved

47

Tip vs. Base Growth Mechanisms

Same initial reaction step: absorbtion,

diffusion and precipitation of carbon

species.

Strength of interaction between catalyst

particle and catalyst support determines

whether particles remains on surface or

is lifted with growing nanotube.

Huang, S.; et al. Nano Lett. 2004 4, 1025.

Kong, J.; et al. Chem. Phys. Lett. 1998, 292, 567.

Ch120a-Goddard-L07,08

Images of nanotubes show catalyst

particles trapped at the ends of

nanotubes in the case of tip growth, or

nanotubes bound to catalysts on

support in the case of base growth.

Alternatively capped nanotube tops

show base growth.

A kite (tip) growth mechanism has been

used to explain the growth of long (order

48

of mm),

well III,

ordered

SWNTs.

© copyright 2011 William

A. Goddard

all rights reserved

Limiting Steps for Growth Rates

Diffusion of reactive species either

through the catalyst particle bulk or across

its surface can play an important role in

determining the rate of nanotube growth.

In the case of carbon species which

dissociate less readily the rate of carbon

supply to the particle can act as the rate

limiting step.

The rate of growth must also take into

account a force balance between the

friction of the nanotube moving through

the surrounding feedstock gas and the

driving force for/from the reaction.

Vinciguerra, V.; et al. Nanotechnol. 2003, 14, 655.

Hofmann, S. et al. Nano Lett. 2007, 7, 602.

Hafner, J. H.; et al. Chem. Phys. Lett. 1998, 296, 195.

Ch120a-Goddard-L07,08

© copyright 2011 William A. Goddard III, all rights reserved

49