+ Analysis of Anomalous Film Growth when Yttrium

+

Analysis of

Anomalous Film

Growth when Yttrium

Oxide Thin Films are

Exposed to 7.2eV

Light

Alison Wells

Dr. David D. Allred

Devon Mortenson

Kristal Chamberlain

+

Background

Group members took some samples to Berkeley for measurements using the Advanced Light

Source.

When they got back needed to put it in the plasma cleaner.

Why? Because there is a sort of “gunk” composed mainly of hydrocarbons deposited on samples.

Problem: the plasma cleaner was broken.

Solution: Use the excimer (VUV) lamp instead.

+

Background Continued

The Mystery

After approximately 5 minutes under the VUV lamp, the sample became visibly thicker.

Use ellipsometry measurements to determine if this is true.

+

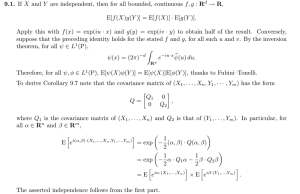

Ellipsometry Measurements: Y2O3

Before cleaning: 24.94 nm

100

80

60

40

20

Generated and Experimental

Model Fit

Exp Y -E 75°

Model Fit

Exp D -E 75°

0

1.0

2.0

3.0

4.0

Photon Energy (eV)

5.0

4 srough

3 polycarb

2 ema y2o3/30% void

1 sio2_jaw

0 si_jaw

6.0

200

100

0

-100

-200

7.0

0.500 nm

0.000 nm

24.733 nm

2.000 nm

1 mm

After 5 min VUV: 31.061 nm

100

80

60

40

20

Generated and Experimental

Model Fit

Exp

Exp

Y -E 70°

Y -E 72°

Exp

Exp

Y -E 74°

Y -E 76°

Exp Y -E 78°

Exp Y -E 80°

Model Fit

Exp

Exp

D -E 70°

D -E 72°

Exp D -E 74°

Exp

Exp

D -E 76°

D -E 78°

Exp D -E 80°

300

200

100

0

0

1.0

2.0

3.0

4.0

Photon Energy (eV)

5.0

-100

6.0

3 srough 0.500 nm

2 y2o3 constants based on 091130b on si 31.061 nm

1 sio2_jaw

0 si_jaw

1.800 nm

1 mm

+

In Search for an Answer

Big question is: What’s going on here?

90

80

70

60

50

40

30

20

10

0

0

Thickness vs. Time under VUV

091130b sample

10 20

Time (min)

30 40

Piece 1

+

First Theories

First thought: the yttrium is not fully oxidized.

Too thick

Is it possible that the VUV lamp is actually depositing material onto the sample?

Not possible that more Y

2

O

3 is being added to film.

Subject a blank silicon substrate to same VUV treatment and look for film deposition.

No growth

+

First Set of Conclusions

It doesn’t seem likely that the VUV lamp is depositing material onto our film.

Oxidation of Silicon Substrate

Thickness decreases in furnace

Only other option is that what is already on the film is somehow being altered.

+

Second theories and Tests (cont.)

Necessity of VUV Interaction with Sample

100

Effects of Glass Shield on Film Growth

90

80

70

60

50

40

30

20

10

0 unshielded sample glass shielded sample before after

+

Second theories and Tests (cont.)

Necessity of an ozone

Comparing Film Growth

100

80

60

40

20

0

Argon purge Nitrogen

Purge

Atmosphere

Before

After

+

New

Theories

Look at Neighboring

Oxide

What would happen to a scandium oxide when exposed to same VUV treatment.

+

Comparing Oxides

Water in the voids

Y2O3

May be slightly hydroscopic

Reactively Sputtered sample

Sc2O3

Insoluble in water

Natural oxidation vs. reactive sputtering

+

Ellipsometry Measurements:

Natural Oxidized Sc2O3

Before VUV: 22.842 nm After 40 min: 23.310 nm

+

Ellipsometry Measurements:

Reactively Sputtered Sc2O3

Before Cleaning: 12.528 nm After 5 min VUV: 13.218 nm

+

Ellipsometry Measurements:

Reactively Sputtered Sc2O3

After 10 min VUV: 14.406 nm After 20 min VUV: 15.524 nm

+

Ellipsometry Measurements:

Reactively Sputtered Sc2O3

After 40 min VUV: 17.902 nm After 70 min VUV: 17.203 nm

+

The Mystery Continues

Future Work

Thicker Films

Use XPS to look at oxygen to metal ration

Observe other oxides

Deposit Silicon cap over samples

+

Thank You

Brigham Young University Physics Department

Dr. David D. Allred

BYU Thin Film Optics Research Group