ANALYSIS OF ANOMALOUS FILM GROWTH WHEN ULTRAVIOLET LIGHT Presenter: Devon R. Mortensen

advertisement

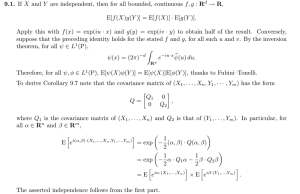

ANALYSIS OF ANOMALOUS FILM GROWTH WHEN YTTRIUM OXIDE IS EXPOSED TO VACUUMULTRAVIOLET LIGHT Presenter: Devon R. Mortensen Contributors: Thomas McConkie David D. Allred The Setup Group members took some samples to Berkeley for measurements using the Advanced Light Source. When they got back we needed to measure the thickness of one of the Y2O3 film samples. Before we could do this we needed to put it in the plasma cleaner. Why? Because there is a sort of “gunk” composed mainly of hydrocarbons that permeates all space and likes to deposit itself on samples. Problem: the plasma cleaner was broken. Solution: Let’s use the excimer (VUV) lamp instead. This lamp generates photons at 7.2eV, which are so energetic that they only go about 1 cm in air before they are absorbed. Enter the Mystery After approximately 5 minutes under the VUV lamp, the sample became visibly thicker. Use ellipsometry measurements to determine if this is true. Before cleaning: 24.94 nm Generated and Experimental 100 200 Model Fit Exp Y -E 75° Model Fit Exp D-E 75° 100 60 0 40 -100 20 0 1.0 2.0 3.0 4.0 5.0 Photon Energy (eV) 6.0 -200 7.0 D in degrees Y in degrees 80 4 3 2 1 0 srough polycarb ema y2o3/30% void sio2_jaw si_jaw 0.500 nm 0.000 nm 24.733 nm 2.000 nm 1 mm Thick.2 =24.733±0.139 nm Ellipsometry Measurements After 5 min VUV: 31.061 nm Generated and Experimental 100 300 Model Fit Exp Y -E 70° Exp Y -E 72° Exp Y -E 74° Exp Y -E 76° Exp Y -E 78° Exp Y -E 80° Model Fit Exp D-E 70° Exp D-E 72° Exp D-E 74° Exp D-E 76° Exp D-E 78° Exp D-E 80° 60 40 20 0 1.0 2.0 200 100 D in degrees Y in degrees 80 3 2 1 0 srough y2o3 constants based on 091130b on si sio2_jaw si_jaw Thick.2 =31.061±0.0717 nm 0 3.0 4.0 Photon Energy (eV) 5.0 -100 6.0 As you can see this is quite a significant change. 24.94 nm 0.500 nm 31.061 nm 1.800 nm 1 mm 31.06 nm Search for the Answer Big question is: What’s going on here? First thought: the yttrium is not fully oxidized. Thickness vs. Time under VUV 091130b sample 90 80 Thickness (nm) 70 60 Piece 1 50 Theory 40 If the yttrium were complete unoxidized expected film growth would be 3.34 nm Actually film growth was 6.12 nm 30 20 10 0 0 10 20 Time (min) 30 40 Second Theory Is it possible that the VUV lamp is actually depositing material onto the sample? Not possible that more Y2O3 is being added to film. Perhaps it is knocking molecules off of the support base and these molecules are finding their way to the sample. Subject a blank silicon substrate to same VUV treatment and look for film deposition. Blank Silicon Wafer Before VUV: Generated and Experimental 50 180 Model Fit Exp Y -E 75° Model Fit Exp D-E 75° 150 120 30 90 20 60 10 0 1.0 30 2.0 3.0 4.0 5.0 Photon Energy (eV) 6.0 srough 0.000 nm y2o3 constants based on 091130b on si after0.000 5 minnm vuv sio2_jaw 2.074 nm si_jaw 1 mm MSE=5.786 Thick.1 =2.074±0.0081 nm 0 7.0 180 Model Fit Exp Y -E 75° Model Fit Exp D-E 75° 40 150 120 30 90 20 60 10 30 2.0 3.0 4.0 5.0 Photon Energy (eV) 6.0 0 7.0 D in degrees Y in degrees 3 2 1 0 After 5 min VUV: Generated and Experimental 50 0 1.0 D in degrees Y in degrees 40 3 2 1 0 srough 0.000 nm y2o3 constants based on 091130b on si after0.000 5 minnm vuv sio2_jaw 2.221 nm si_jaw 1 mm MSE=6.713 Thick.1 =2.221±0.00942 nm Blank Silicon Wafer After 10 min VUV: Generated and Experimental 50 180 Model Fit Exp Y -E 75° Model Fit Exp D-E 75° 150 120 30 90 20 60 10 0 1.0 D in degrees Y in degrees 40 30 2.0 3.0 4.0 5.0 Photon Energy (eV) 6.0 3 2 1 0 srough y2o3 constants based on 091130b on si sio2_jaw si_jaw MSE=9.096 0.000 nm 0.000 nm 1.797 nm 1 mm Thick.1 =1.797±0.012nm 0 7.0 After 25 min VUV: Generated and Experimental 50 180 Model Fit Exp Y -E 75° Model Fit Exp D-E 75° 150 120 30 90 20 60 10 0 1.0 30 2.0 3.0 4.0 5.0 Photon Energy (eV) 6.0 0 7.0 D in degrees Y in degrees 40 3 2 1 0 srough 0.100 nm ema y2o3 constants based on 091130b on si0.000 after 10 nmmin sio2_jaw 1.863 nm si_jaw 1 mm MSE=8.125 Thick.1=1.863±0.0112nm First Set of Conclusions No apparent change in thickness of the silicon witness. It doesn’t seem likely that the VUV lamp is depositing material onto our film. Only other option is that what is already on the film is somehow being altered. It is possible that the Y2O3 is catalyzing the oxidation of the silicon wafer underneath. Let’s take a closer look at what is happening to the optical constants: Optical Constants At 2.4 eV (516 nm light) Y2O3 has an index of refraction of 1.938 Silicon dioxide has an index of 1.466 The formation of SiO2 should lower the total index of the material. The data was fit using a Cauchy model, allowing the parameters to vary to fit for optical constants. Optical Constants Index of Refraction at 2.4 eV 2 1.9 n 1.8 Sample 1.7 SiO2 Y2O3 Y2O3 w/ 20% voids 1.6 1.5 1.4 0 5 10 15 Exposure time to VUV (min) 20 Effects of the Furnace It seems that the possibility of silicon oxidation is a viable one. If the silicon has indeed become oxidized the thickness should not go down when placed in a furnace. SiO2 is quite stable and silicon wants to be oxidized anyway. Before furnace: Generated and Experimental 100 300 Model Fit Exp Y -E 70° Exp Y -E 72° Exp Y -E 74° Exp Y -E 76° Exp Y -E 78° Exp Y -E 80° Model Fit Exp D-E 70° Exp D-E 72° Exp D-E 74° Exp D-E 76° Exp D-E 78° Exp D-E 80° 60 40 20 0 1.0 2.0 3.0 4.0 5.0 Photon Energy (eV) 200 D in degrees Y in degrees 80 100 0 6.0 0.500 nm 98.259 nm 1.800 nm 1 mm MSE=58.82 Thick.2 =98.259±0.168 nm -200 7.0 After 2 hours in furnace: Generated and Experimental 150 Model Fit Exp Y -E 70° Exp Y -E 72° Exp Y -E 74° Exp Y -E 76° Exp Y -E 78° Exp Y -E 80° Model Fit Exp D-E 70° Exp D-E 72° Exp D-E 74° Exp D-E 76° Exp D-E 78° Exp D-E 80° 60 40 20 2.0 3.0 4.0 5.0 Photon Energy (eV) 100 50 0 D in degrees Y in degrees srough y2o3 constants based on 091130b on si sio2_jaw si_jaw -100 80 0 1.0 3 2 1 0 3 2 1 0 srough y2o3 constants based on 091130b on si sio2_jaw si_jaw 0.500 nm 16.938 nm 1.800 nm 1 mm MSE=17.41 Thick.2 =16.938±0.016 nm -50 6.0 -100 7.0 Over an 80% decrease in thickness The Mystery Continues Maybe the sample is simply being puffed up. Boiling water Ozonide The Mystery Continues How would we be able to tell? TEM imaging might be able to reveal what is happening to the structure of our sample. Need to reconcile one important piece of data. A piece of the same sample, when first put in the plasma cleaner, exhibits none of these effects.