Single Walled Carbon Nanotube Magnetometer for Planetary Exploration

advertisement

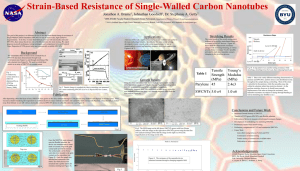

Single Walled Carbon Nanotube Magnetometer for Planetary Exploration Jonathon A. 1a Brame , Johnathan 1b Goodsell , Bryan 2 Hicks , Dr. 1a David Allred and Dr. Stephanie A. 3 Getty 1 2007 ESMD Faculty/Student Research Team Participant, a Department of Physics & Astronomy, b Department of Mechanical Engineering, Brigham Young University, Provo, UT, 2 2007 Rocky Mountain NASA Space Grant Consortium Summer Internship, Department of Physics & Astronomy, Brigham Young University, Provo, UT, 3 Abstract NASA Goddard Space Flight Center, Materials Engineering Branch, Code 541, Greenbelt, MD, Stephanie.A.Getty@nasa.gov Applications Fig. 4 – Surface of Mars The small size and low mass of this device, coupled with high spatial resolution makes it ideal for exploration of planetary magnetic fields as well as localized magnetic mapping of fields such as those found on Mars. The design concept can also be adapted to strain-sensing applications, including acceleration, wind speed, temperature, and fluid flow measurements. The goal of this project is to fabricate a low mass, strain-based magnetic sensor for use in planetary science and exploration missions. The operating principle exploits the sensitivity of Single Walled Carbon Nanotube (SWCNT) electrical properties to strain. The sensor design resembles a classical compass with electronic readout. The sensor consists of a magnetically responsive, high aspect-ratio Fe component suspended on a free-standing mat of electrically contacted SWCNTs. During operation, torque on the Fe needle will transduce ambient magnetic field strength into an electronic signal. We report on device fabrication and preliminary measurements. Background SWCNTs are one-dimensional tubes of carbon atoms bonded hexagonally that have outstanding electrical, thermal, and mechanical properties. Typical diameter is approximately 1 nm, and the length of a nanotube can be thousands of times larger than the diameter. The atomic structure of a SWCNT can be conceptualized by rolling up a single sheet of graphite (graphene) and trimming off the overlap to form a seamless cylinder. Courtesy Fuhrer Group Prior Work During the first year of the BYU-NASA collaboration program (2006), we were able to do some preliminary work to enhance and validate the concept of the magnetometer as well as increase our understanding of networks of SWCNTs. Some of the projects included increasing SWCNT growth density, testing the strain-based resistance of nanotube networks, and measuring the resistive response of nanotube networks to changes in magnetic field. Fig. 2a – SWCNTs grown with iron nitrate catalyst Fig. 2b – SWCNTs grown with thin film iron catalyst After growing carbon nanotubes on the SiO2 substrate, we use e-beam lithography to define a pattern for gold evaporation. At right is a top and side view of the device after the gold evaporation. Purple represents silicon dioxide, Grey represents Silicon, Yellow represents gold, and Black represents the nanotubes. Fig. 5 – Earth’s Magnetosphere Fig. 6 – Mechanism of operation Concept Single Walled Carbon Nanotubes (SWCNT) have been shown to have large changes in resistance with applied strain (Tombler et al. Nature 2000). We seek to extend that characteristic from a single tube to a network of tubes as grown on the substrate. By suspending an iron needle on such a network of nanotubes, a magnetic field will cause the needle to deflect, straining the nanotubes and changing the net resistance of the network. Fig. 1 – SWCNT atomic structure After depositing a thin film layer of iron, SWCNTs were grown on the SiO2 substrate through a CVD process using methane and ethylene as the feed gases. Next we use electron-beam lithography to open a pattern for the gold contact pads (deposited through thermal evaporation with a chromium under-layer for adhesion). Once the contact pads are in place, another e-beam lithography step allows us to deposit the iron needle. We deposit a 300 nm Fe needle between two 30 nm layers of chromium to protect the needle during the etching process. In order to free the needle from the substrate, we use wet chemical etching to create a trench underneath the needle. In order to reduce the risk of damage due to surface tension as the device dries, we remove liquid in a Critical Point Dryer (CPD). Gold Contacts The surface of Mars and the Earth’s magnetospherePrime subjects for magnetometry measurements. SWNT Magnetometer Fabrication • Persistent magnetic moment of Fe “needle” Iron Needle • Compass mechanism After electrically testing the gold contacts to make sure that the nanotube network contacts the gold pads, we deposit a thin iron needle between the gold contacts (represented by brown in the diagram). We encase the iron needle between two 30 nm chromium evaporations to help passivate the iron in preparation for the wet etching. • Torque bends SWCNTs ST5 Fluxgate • Monitor electrical conductance vs. field Max Op 450°C 100°C Temp Sensor 1cm x 1cm x 4cm x 4cm x 6cm Dimensions 100nm Sensor -5 75 g 10 g Mass Sensor Op -3 -2 50 mW 10 - 10 mW Power Table 1. Comparison of SWCNT Magnetometer to miniaturized fluxgate magnetometer flown on ST5 mission (UCLA) Trench Etching The etching process involves first immersing the device in a Buffered Oxide Etch (BOE) to etch the SiO2. We use photoresist to shield the rest of the substrate while using an optical microscope to expose the area surrounding the needle. After the BOE, we etch the silicon with KOH at 65º C to make a trench deep enough to allow the iron needle to rotate out of the plane of the substrate. Results Fig. 7 – Intrinsic magnetic field response of SWCNT network At right is an image taken with a scanning electron microscope of a successful device. The needle is suspended over the trench by a mat of nanotubes (note the rolled mat of tubes on the left end of the device). Increased Growth Density: The figure above on the left shows characteristic growth of SWCNTs using an iron nitrate solution catalyst. On the right is a characteristic growth using and indirect evaporation of thin-film iron, maximized at a growth temperature of 950°C. SWCNTs Fig. 9 – NanoCompass fabrication procedure Fig. 10 – Prototype NanoCompass Conclusions and Future Work Au Electrode Au Electrode Fe Needle • Completed device for testing • More robust etching process • Measurement of resistance of suspended nanotube networks over a trench (with no needle) • Fig. 3 – Strain response of flexible SWCNT network device on parylene substrate Future Work Reproduce dense SWCNT growth at BYU Magnetic Field (T) Make electronic measurements of device with AFM Magnetic Testing: Above is a graph of the resistance of a nanotube network with a changing applied magnetic field. It is important that a magnetic field does not change the inherent resistance of the nanotubes so that we can isolate the resistance change due to the torque from the iron needle. No changes were seen in magnetic fields up to 0.35 Tesla. Strain-Based Resistance: At left is a graph of the resistance of a nanotube network as it was stretched from slack through equilibrium to a maximum of 20 µm. The measurements were made on a mat of nanotubes that had been lifted off the SiO2 substrate into a flexible Parylene substrate through a process developed last summer. Fig. 8 – Preliminary magnetic field response of NanoCompass prototype 0 0.04 0.08 0.12 0.16 0.20 Magnetic Field (T) 0.24 0.28 At left is a plot of current measured by the magnetometer device versus changing magnetic field up to 0.3T. Device response is shown for increasing and decreasing magnetic field over one cycle. No conclusive device response was seen. Optimization of the device design is underway to increase sensor response to magnetic field, including segmented electrodes to isolate SWCNTs that experience largest strain and a needle with reduced width for higher magnetic coercivity. Further strain testing measurements Acknowledgements ESMD Program, Rocky Mountain NASA Space Grant Consortium BYU- Dr. Robert Davis, Dr. Aaron Hawkins GSFC- Rachel Bis, Stacy Snyder, C. Taylor, D. Dove, C. Hoffman, L. Wang