Life Cycle Cost Analysis Research at MIT

advertisement

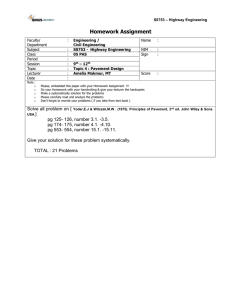

Pavement Vehicle Interactions – Does it Matter for Virginia? Franz-Josef Ulm, Mehdi Akbarian, Arghavan Louhghalam ACPA. Virginia Concrete Conference March 6, 2014 With the support of the VDOT Team – Thank YOU! Motivation: Carbon Management Pavement design and performance: – Fuel saving – Cost saving – GHG reduction • Strategy for reducing air pollution! non profit support group for the Route 29 Bypass Slide 2 OUTLINE • • This is not about Concrete vs. Asphalt, this is about unleashing opportunities for Greenhouse Gas savings Pavement-Vehicle Interaction: • – Roughness/ Vehicle Dissipation – Deflection/ Pavement Dissipation Data Application: • Carbon Management: how to move forward – US Network – VA Network 3 Slide 3 Context: Rolling Resistance • Force Distribution in a passenger car vs. speed as a percentage of available power output (Beuving et al., 2004; cited in Pouget et al. 2012) Due to PVIs: Texture, Roughness and Deflection Slide 4 Key Drivers of Rolling Resistance • Pavement Texture: Tire industry. Critical for Safety. Tire-Pavement contact area. • Roughness/Smoothness*: – Absolute Value = Vehicle dependent. – Evolution in Time: Material Specific • Deflection/Dissipation Induced PVI**: – Critical Importance of Pavement Design Parameters: Stiffness, Thickness matters! – Speed and Temperature Dependent, specifically for inter-city pavement systems *Zaabar, I., Chatti, K. 2010. Calibration of HDM-4 Models for Estimating the Effect of Pavement Roughness on Fuel Consumption for U.S. Conditions. Transportation Research Record: Journal of the Transportation Research Board, No. 2155. Pages 105-116. ** Akbarian M., Moeini S.S., Ulm F-J, Nazzal M. 2012. Mechanistic Approach to Pavement-Vehicle Interaction and Its Impact on Life-Cycle Assessment. Transportation Research Record: Journal of the Transportation Research Board, No. 2306. Pages 171-179. Slide 5 ROUGHNESS / IRI: Dissipated Energy VEHICLE–SPECIFIC ENERGY DISSIPATION & EXCESS FUEL CONSUMPTION • Quarter-Car Model* • Mechanistic/PSD**: 𝛿𝐸 = 1 1 2 𝐶𝑆 𝑧 = 𝐶𝑆 (𝜎𝑧 )2 with: 𝑐 𝜎𝑧 = 𝒛(𝒕) 𝐶𝑆 𝑐 𝑐 2/𝜋 IRI • HDM-4 Model***: 𝛿𝐸 = %𝐸0 IRI−𝐼𝑅𝐼0 Vehicle Specific IRI measured at c=80 km/h = 50 mph 𝐶𝑆 = Damping of Suspension System (Vehicle Specific) (*) Sayers et al. (1986). World Bank Technical paper 46 Reference IRI-Value (**) Sun et al. (2001). J. Transp. Engrg., 127(2), 105-111. (***) Zaabar I., Chatti K. (2010) TRB, No. 2155, 105-116. Slide 6 ROUGHNESS: HDM-4 MODEL 𝛿𝐸 = %𝐸0 IRI−𝐼𝑅𝐼0 • Input: • Zaaber & Chatti (2010) – – – – – Measured IRI (t) Reference IRI, 𝐼𝑅𝐼0 Vehicle Type Traffic Volume (AADT, AADTT) Truck Traffic Distribution • Output: – Excess Fuel Consumption due to Roughness – For vehicle type and total *Zaabar, I., Chatti, K. 2010. Calibration of HDM-4 Models for Estimating the Effect of Pavement Roughness on Fuel Consumption for U.S. Conditions. Transportation Research Record: Journal of the Transportation Research Board, No. 2155. Pages 105-116. Slide 7 MIT Model Gen II: Viscoelastic Top Layer Consideration of Top-Layer Viscoelastic behavior, including temperature shift factor: P c Relaxation Time 𝜏 = 𝜏0 𝑇0 × 𝑎 𝑇 (𝑇) s – Bituminous Materials* −𝐶1 (𝑇 − 𝑇𝑟𝑒𝑓 ) 𝐶2 + (𝑇 − 𝑇𝑟𝑒𝑓 ) 𝑎 𝑇 = exp Winkler Length 𝓁𝒔 = 4 s k – Cementitious Materials**: 𝑎 𝑇 = exp 𝑈𝑐 h = tE E Temperature dependence 1 1 − 𝑇 𝑇𝑟𝑒𝑓 𝐸𝐼/𝑘 𝒄𝒄𝒓 = 𝓁𝑠 (𝑘/𝑚)1/2 * Pouget et al. (2012); William, Landel, Ferry (1980) ** Bazant (1995) Speed Dependence Slide 8 Calibration/Validation | Asphalt Lit. Data 1.4 c= 100 km/h DISSIPATED ENERGY [MJ/km] Calibration c=100 km/h 1.2 • Model-Based Simulations 1 0.8 Pouget et al. (2012) 0.6 MIT Model 0.4 𝜏(𝑇) = 𝜏0 𝑇0 × 𝑎 𝑇 (𝑇) 0.2 0 0 20 40 60 80 TEMPERATURE [Deg.C] 1.6 c= 50 km/h Validation c=50 km/h 1.4 DISSIPATED ENERGY [MJ/km] 𝑐𝑐𝑟 𝑃2 𝑐 𝝉(𝑻)𝑐𝑐𝑟 𝛿𝐸 = × 𝐹 ;𝜁 = 𝑐 𝑐𝑐𝑟 𝓁𝑠 𝑏𝑘𝓁2𝑠 1.2 1 0.8 𝒄 = Vehicle speed 𝑃 = 32.4 ton truck (distribution of loads according to HS 20-44) 𝑏 = 3.6 m (lane width) 𝐸, 𝑘, ℎ = 40,264 MPa, 35 MPa/m, 0.22 m 𝝉(𝑇0 = 283 K) = 0.015 s Pouget et al. (2012) 0.6 MIT Model 0.4 0.2 0 0 20 40 TEMPERATURE [Deg.C] 60 80 Slide 9 New Feature: Temperature and Speed Dependence DISSIPATED ENERGY [MJ/km] 0.35 0.3 0.25 0.2 0.15 68 Deg. F Gen I 0.1 50 Deg. F 0.05 0 0 50 100 SPEED [km/h] (Example taken from Pouget et al. (2012) Slide 10 Can we do better? – Yes, we can! Pavement Roughness Pavement Deflection 2011 MIT-Model PVI Impact MEPDG Structure and Material Slide 11 LCA “plus”: MOVING LCA IN THE DESIGN SPACE INPUT: - Structure - Materials - Traffic - Climate - Design Criteria MEPDG Structurally Sound Design OUTPUT: - E(t) - IRI(t) - Maintenance - Traffic-evolution OUTPUT: - Comparative Design - Design Alternatives Sustainable Design LCA/LCCA OUTPUT: - Fuel Con. - GHG - Costs Embodied + Use Slide 12 Network Application US and VA Slide 13 FHWA/LTPP General Pavement Study sections (GPS) Data: Roughness • IRI (Year) • Traffic • Location • Pavement type Deflection: • Top layer modulus E • Subgrade modulus k • Top layer thickness h • Other layer properties AC PCC Com GPS1: AC on Granular Base GPS3: Jointed Plain CP (JPCP) GPS6: AC Overlay of AC Pavement GPS2: AC on Bound Base GPS4: Jointed Reinforced CP (JRCP) GPS7: AC Overlay of PCC GPS5: Continuously Reinf. CP (CRCP) GPS9: PCC Overlay of PCC Slide 14 VA Interstate: Road Classification VA Label Type LTPP Equivalent BIT Bituminous GPS 1,2 JRCP Jointed reinforced CP GPS 4 CRCP Continuously reinforced CP GPS 5 BOJ Bituminous over JPCP GPS 6 BOC Bituminous over CRCP GPS 9 3% BIT BOC 18% BOJ CRCP JRCP 7% 7% Pavement type analyzed Type 65% Asphalt (BIT) Concrete (CRCP, JRCP) Composite (BOC, BOJ) Total Lane-mile Center-mile 3,131 490 1,221 4,841 Slide 15 1,416 174 459 2,050 VA Interstate: Data Overview Data: • • • • • • • • 15 interstates, 2 direction Years: 2007-2013 Section ID Section milepost AADT, AADTT Layer thicknesses Material properties (2007) IRI (t) Pavement Type AC Com PCC Slide 16 Annual Average Daily Truck Traffic (AADTT) AADTT Slide 17 Deflection -Induced PVI Slide 18 Temperature and Speed Sensitivity: AC in VA 𝑑𝑤 𝑐𝑐𝑟 𝑃2 𝑐 𝝉(𝑻)𝑐𝑐𝑟 𝛿𝐸 = −𝑃 = × 𝐹 ; 𝜁 = 𝑑𝑋 𝑐 𝑏𝑘𝓁2𝑠 𝑐𝑐𝑟 𝓁𝑠 Asphalt Concrete (BIT) Asphalt Concrete (BIT) 1.4 1.4 1.2 1.2 1 0.8 0.6 0.8 0.6 0.4 0.4 0.2 0.2 0 0.001 0.01 0.1 Dissipated Energy [MJ/km] c=60 mph c=20 mph T=20C/65F PDF/1 PDF/1 1 T=10C/50F 1 Temperature sensitivity one order of magnitude higher dissipation (T= 50 vs. 65 F) 𝑃 = 37 tons (3 axles); 𝑐 = 62.5 mph; τ0 = 0.015 s; VA Interstate database for distributions of (𝐸, 𝑘, ℎ) of AC 0 0.001 0.01 0.1 Dissipated Energy [MJ/km] 1 Speed Sensitivity half order of magnitude higher dissipation (𝑐 = 20 vs. 60 mph) 𝑃 = 37 tons (3 axles); 𝑇 = 10℃/50℉;Slide τ0 = 19 0.015 s Temperature Sensitivity: PCC in VA 𝑑𝑤 𝑐𝑐𝑟 𝑃2 𝑐 𝝉(𝑻)𝑐𝑐𝑟 𝛿𝐸 = −𝑃 = × 𝐹 ; 𝜁 = 𝑑𝑋 𝑐 𝑏𝑘𝓁2𝑠 𝑐𝑐𝑟 𝓁𝑠 Concrete (JRCP, CRCP) Concrete (JRCP, CRCP) 1.6 1.4 c=20 mph T=10C/50F 2 c=60 mph 1 PDF/1 PDF/1 1.2 2.5 T=20C/65F 0.8 0.6 1.5 1 0.4 0.5 0.2 0 0.001 0.01 0.1 Dissipated Energy [MJ/km] Temperature sensitivity Small! 1 0 0.001 0.01 0.1 Dissipated Energy [MJ/km] Speed Sensitivity Small [For pure comparison, assume same 𝜏0 (𝑇0 = 283 K) as for asphalt] 𝑃 = 37 tons (3 axles); 𝑐 = 62.5 mph; τ0 = 0.015 s; VA interstate database for distributions of (𝐸, 𝑘, ℎ) of PCC 20s 𝑃 = 37 tons (3 axles); 𝑇 = 10℃/50℉; τ0Slide = 0.015 1 Would this matter for VA? Order of magnitude difference BIT/AC PCC Temperature sensitivity 10 Deg. can entail one order of magnitude of higher energy dissipation; thus fuel consumption. Temperature sensitivity 10 Deg. can entail half order of magnitude of higher energy dissipation; thus fuel consumption. Assume: Bit @ 95%. P=37 tons (3 axles); τ0=0.015s Assume: PCC @ 95%. P=37 tons (3 axles); τ0=0.015s * Temp data from National Oceanic and Atmospheric Administration (esrl.noaa.gov) Slide 21 VA Network: PVI Deflection – Truck c= 100 km/h=62.6 mph; T= 16 C/61 F 1.6 Bituminous Composite Concrete 1.4 1.2 PDF/1 1 0.8 0.6 0.4 0.2 0 0.0001 0.001 0.01 Excess Fuel Consumption (gal/mile) Excess fuel consumption due to PVI deflection is 10 times higher on bituminous pavements Slide 22 Annual Excess Fuel Consumption: PVI Deflection *2013 data c= 100 km/h=62.6 mph; T= 16 C/61 F FC (gallon/mile) Slide 23 Summary | For Discussion • PVI-model Gen II: – Accounts for the effect of temperature and vehicle speed on the dissipated energy. – Quantifies asphalt and concrete sensitivity to speed and temperature. – Requires one material input parameter: relaxation time. So far, calibrated and validated using literature data. Link with Master Curve. – Simple to use, easy to calculate fuel consumption in excel spreadsheet; thus for LCA use phase… Slide 24 IRI-Induced PVI Slide 25 IRI: US Network – VA Data Comparison 0.6 Frequency 0.5 0.4 VA Network 0.3 US Network 0.2 0.1 0 <60 60-94 95-119 120-144 145-170 171-194 195-220 > 220 171-194 195-220 > 220 IRI (in/mile) <60 60-94 95-119 120-144 145-170 1.2 1 0.8 VA Network 0.6 US Network 0.4 0.2 0 IRI distribution of Virginia and the US network are very similar. Slide 26 VA – Roughness *2013 data 0.7 Frequency 0.6 0.5 0.4 VA Concrete 0.3 VA Asphalt 0.2 VA Composite 0.1 0 <60 60-94 95-119 120-144 145-170 171-194 195-220 > 220 IRI (in/mile) <60 60-94 95-119 120-144 145-170 171-194 195-220 > 220 1.2 1 0.8 Concrete 0.6 Asphalt 0.4 Composite 0.2 0 Asphalt and composite pavements are maintained equally. Not concrete Slide 27 IRI depends on pavement maintenance <60 60-94 95-119 120-144 145-170 171-194 195-220 > 220 1.2 1 0.8 Concrete 0.6 Asphalt Composite 0.4 VA (2013) 0.2 0 <60 60-94 95-119 120-144 145-170 171-194 195-220 > 220 1.2 1 0.8 Concrete Asphalt Composite 0.6 0.4 0.2 MN (2011) 0 Slide 28 Pavement Roughness (IRI) *2013 data IRI (in/mile) Slide 29 Excess Fuel Consumption: PVI Roughness *2013 data FC (gallon/mile) Slide 30 Cost aggregated for: - Interstate pavement - Primary pavement - Secondary pavement Deficient pavement IRI: - Poor: 140-199 - Very poor: >200 Pavement Expenditure (Millions of $) Annual Expenditure on all Pavements in VA $400 Asphalt Pavement $350 Concrete Pavement $300 $250 $200 $150 $100 $50 $0 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 Year Deficient lane miles due to ride quality by pavement type – Interstate Pavement Type AC PCC Total lane-mile (% total) 3,131 (65%) 490 (10%) 3,621 (75%) Deficient lane-miles (% total)* 157 (46%) 181 (54%) 338 (100%) *VDOT. State of The Pavement 2012. http://www.virginiadot.org/info/resources/State_of_the_Pavement_2012.pdf Slide 31 SUMMARY: IRI-induced PVI • IRI is vehicle specific • Concrete pavements are under-maintained • Difference between pavement systems is IRIdevelopment and pavement aging. Data not consistent with national analyses • Model Development: 𝛿𝐸 = %𝐸0 IRI−𝐼𝑅𝐼0 Reference 𝐼𝑅𝐼0 = 63 in/mile = Political decision Higher value of 𝐼𝑅𝐼0 reduces the number of roads contributing to excess fuel consumption. Slide 32 Total PVI Impact Slide 33 Network: Annual PVI Truck* – excess FC per mile Annual Excess Fuel Consumption (Gal/mile) 16000 Roughness Deflection 160 14000 140 12000 120 10000 100 8000 80 6000 60 4000 40 2000 20 0 0 BIT BOC BOJ CRCP Annual Excess CO2e Emissions (tons/mile) c= 100 km/h=62.6 mph; T= 16 C/61 F *2013 data JRCP Impact Reduction through enhanced pavement design and management Slide 34 Network: Annual PVI Truck – Total FC c= 100 km/h=62.6 mph; T= 16 C/61 F 70,000 6,000,000 60,000 5,000,000 50,000 4,000,000 40,000 3,000,000 30,000 2,000,000 20,000 1,000,000 10,000 0 0 2007 2008 2009 2010 Annual Truck FC Roughness 2011 2012 2013 Annual Truck FC Deflection Slide 35 Excess CO2e Emissions (tons) Excess Fuel Consumption (Gallons) 7,000,000 PVI Total Impact: Roughness and Deflection *2013 data: Trucks c= 100 km/h=62.6 mph; T= 16 C/61 F FC (gallon/mile) Slide 36 CARBON MANAGEMENT = Pavement Performance! ENGINEERING 100% • PVIs contribute highly to pavement induced fuel consumption and GHG emissions • Concrete pavements not utilized to same performance as in other roadway networks – High deficient lane-miles – Older pavements • Room for GHG reduction! Moving tire (top view) is on slope = Deflection induced eXtra-Fuel Consumption Slide 37 CARBON MANAGEMENT = Cost – Benefit! ECONOMICS 100% ECONOMICS = LINGUA FRANCA OF IMPLEMENTATION • LCCA is tool for supporting design decisions • Analyses typically occur after design process is complete • Standard practice does not account for uncertainty • FHWA does not provide guidance on characterizing inputs and uncertainty Slide 38 LC C A VA LU E P RO P O S I T I O N • Context: $ 2 Trillion Infra-structure renewal job within tightest budgetary constraints. • Problem: Volatility of construction materials pricing for a fiscally sound decision making. ECONOMICS Decision Makers (local, national, and beyond) * Swei, Gregory & Kirchain (2013) • Solution*: A new LCCA methodology with probabilistic cost modeling of pavement projects, so that decisionmakers: – Understand the risk of an investment; – Select a design based on risk perspective. I M P L E M E N TAT I O N @ State Level: Case Study Slide 39 I N V E S T – I N N O VAT E – I N V I G O R AT E - I M P L E M E N T Uncertainty is pervasive in pavement LCCA Cash Flow Decisions long before construction Uncertainty in unit construction costs Construction CSHub approach characterizes uncertainty for all three areas Uncertainty & Risk Long life-cycle Uncertainty in material price evolution Ope ra t i on Uncertainty in timing of M&R activities Slide 40 CSHub LCCA methodology is integrated with pavement design process Propagate uncertainty to understand risk Statistically Characterize Uncertainty Present MEPDG Output Relative risk Is the difference significant? Future LCCA Model FHWA guidance is limited Characterize drivers of uncertainty Slide 41 IMPLEMENTATION: LCCA – Why does it matter? Translating price volatility into value proposition for Decision Makers • ECONOMICS = LINGUA FRANCA OF IMPLEMENTATION 100% 90% Minimizing Risk ECONOMICS 100% Cumulative Probability 80% 70% 60% 50% Gambling with Cost overrun 40% Design A 30% Design B 20% 10% 0% 26.8 27.0 27.2 27.4 27.6 NPV (Millions of $'s) 27.8 Slide 42 What’s next? Analysis: • LCCA & PVI • Pavement maintenance and PVI • Impacts from pavement age Data needs: • Longer timeframe (7 years doesn’t cover full pavement lifecycle) • Pavement maintenances and activity • More PCC data (i.e. I-295) Implementation: • Let’s see where this can take us … TOGETHER ! Slide 43 We seek your input! Thank you. References: • Louhghalam, A.; Akbarian, M., Ulm, F-J. (2013) Fluegge's Conjecture: Dissipation vs. Deflection Induced Pavement-Vehicle-Interactions (PVI); J. Engrg. Mech., ASCE. • Louhghalam, A.; Akbarian, M., Ulm, F-J. (2013) Scaling relations of dissipation-induced pavement-vehicleinteractions; TRB. • http://web.mit.edu/cshub/ Slide 44 Predicting the future? • Beyond my pay grade, but… • CARBON MANAGEMENT is a vehicle of INFRASTUCTURE MANAGEMENT • Quantitative Sustainability • Together, let’s make it a reality… Slide 45 ∆𝐈𝐑𝐈 ∆𝐭 : 𝐀𝐀𝐃𝐓𝐓 Main distresses of PCC pavements JPCP Distresses (%slabs) Interstate D4 D5 D9 Transverse Cracking 11% 10% 0% Corner Breaks 1% 1% 2% PCC Patching 8% 2% 2% Asphalt Patching 13% 12% 1% Average Pavement Roughness (in/mile) Poor 140-199 JRCP IRI 146 128 104 AC IRI 88 87 73 Pavement IRI is a function of pavement maintenance Slide 46 Comparison: Gen 1 – Gen 2 Model GPS-1: AC on Granular Base 0.5 0.45 0.5 T=10C/50F (+/- 10C) c=100 km/h (62.5mph) Gen-1 0.35 0.35 0.3 0.3 0.25 0.2 0.1 0.1 0.05 0.05 0.01 0.1 1 Gen-II 0.2 0.15 0.001 Gen-I 0.25 0.15 0 0.0001 T=10C/50F (+/- 10C) c=100 km/h (62.5mph) 0.4 PDF/1 PDF/1 0.45 Gen-II 0.4 0 0.0001 10 𝑐 = Vehicle speed 𝑃 = 36 tons (on 3 axles) 𝑏 = 3.6 m (lane width) 𝐸, 𝑘, ℎ = (GPS 1, 2 - LTPP Network) 𝜏(𝑇0 = 283 K) = 0.015 s 𝑇 = Temperature Gen 2 INPUT DISSIPATED ENERGY [Ltr/100km] Gen 1 INPUT GPS-2: AC on Treated Base 0.001 0.01 0.1 1 DISSIPATED ENERGY [Ltr/100km] 10 That is, Gen I model is a lower bound. Gen II is more accurate for local response, but requires (at least) one more parameter. Slide 47 Viscoelastic Modeling | Master Curve Temperature −𝐶1 (𝑇 − 𝑇𝑟𝑒𝑓 ) 𝑎 𝑇 = exp 𝐶2 + (𝑇 − 𝑇𝑟𝑒𝑓 ) Simplified approach: 1 - Accounts for the load frequency effect using a simple Maxwell model in frequency range of interest. 2 - Accounts for temperature effect in the same way as asphalt literature (e.g. William Landel Ferry equation) From Pouget et al. (2012) Load Frequency (Speed) Slide 48 Principle of Viscoelastic Model Fitting (Using Master Curve) complicated viscoelastic model Simplified (Maxwell) viscoelastic model Fit for the entire frequency range Fit for applicable frequency range Find t and E Frequency range of interest Simplified Maxwell model along with the WLF law accounts for the temperature dependency. Maxwell model with temperature dependency Slide 49