Elastically Coupled Beam Apparatus

advertisement

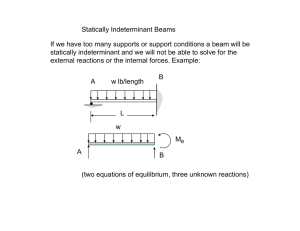

INSTRUCTIONAL MANUAL OF ELASTICALLY COUPLED BEAM APPARATUS By: ENGINEERING MODELS & EQUIPMENT Regd. Office: Mahavir Jain Market 7 – Civil Lines, Post Box No. – 13 Roorkee – 247 667 Phone: 01332 – 275639, 273121 (Resi) Fax: 01332 – 271621 E-mail: enggmod@nde.vsnl.net.in, enggmodels@sancharnet.in Visit us at: www.enggmod.com Factory & Works: Adarsh Nagar New Hardwar Road Roorkee – 247 667 Phone: 01332 – 273721 2 ELASTICALLY COUPLED BEAM APPARATUS CONTENTS: Page No. 1.0 Theory 03 2.0 Objective 08 3.0 Apparatus 08 4.0 Suggested Experimental work 08 5.0 Results & Discussions 08 6.0 Sample Data Sheet 09 7.0 Precautions 09 3 ELASTICALLY COUPLED BEAM APPARATUS 1.0 THEORY: A B R1 C R3 R2 A1 A2 E1 A3 E2 D W L/2 L E3 F E L/2 L Let R1, R2, R3 be the internal forces in the three suspension rods AD, BE and CF respectively. Lengths AD=BE=CF=L Lengths AB=BC=DE=EF=L Moment of inertia of the cross section of the beam ABC and DEF = I Young’s Modulus of elasticity of the material of the beam ABC and DEF= E Modulus of elasticity of the material of rods AD, BE and CF =E1, E2, E3 respectively. Cross sectional area of rods AD, BE and CF= A1, A2, A3 respectively. Condition 1 When support B exists, the beam ABC becomes in-operative. The central deflection at point E, of beam DEF due to load W at G and the upward force R2 at E, relative to the deflected positions of points D and F is given by 11 WL3 R2 L3 y (1) 96 EI 6 EI D Y1 E F Y1 Y3 2 Y2 Y3 F1 Y D1 E1 4 The case is equivalent to simply supported beam supported at D and F subjected to loads W and R2 at G and E respectively. Now it is required to find the deflection at the point E. the deflection shall be obtained by area moment theorem for two different loading. 1 L 3 WL 2 L 1 3L 3 WL L 1 3L DD ' 2 2 8 EI 3 2 2 2 8 EI 2 3 2 5 WL3 16 EI R1 R2 R3 E G D F Y W Fig. (a) L/2 L/2 L 3 WL 8 EI Fig. (b) B.M. D. D F E Fig. (c) E" W E' L/2 3/2 L D' D" E1’ Fig. (d) R2 E1 " D Fig. (e) F E R2 L 2 EI B.M.D. 5 DD ' 5 WL3 EE ' 2 32 EI 1 1 WL L E ' E" L 2 4 EI 3 3 WL 24 EI Downward deflection due to W y1 EE" EE ' E ' E" 1 5 32 24 11 WL3 96 EI Also, R L3 1 R L DD" 2 2 L L 2 2 2 EI 2 EI 3 R L 1 EE '1 DD" 2 2 4 EI 1 R2 L L R2 L3 E '1 E"1 L 2 2 EI 3 12 EI Upward deflection due to R2 y 2 EE"1 EE'1 E'1 E"1 R L3 1 1 R L3 2 ( ) 2 EI 4 12 6 EI WL3 EI Net deflection y at point E= y1 y 2 Let 11 WL3 R2 L3 96 EI 6 EI elongation of suspension rod AD =Y1 elongation of suspension rod BE =Y2 elongation of suspension rod CF =Y3 then total deflection of point E relative to its original position is Y Y 11 WL3 R2 L3 Y2 1 3 2 96 EI 6 EI Now, we know that Y1 RL R1 L R L , Y2 2 , and Y3 3 A1 E1 A2 E 2 A3 E3 Substituting the values of Y1, Y2, and Y3 in Eq. (2) (2) 6 R3 L 11 WL3 R2 L R 2 L3 1 R L (3) 1 A2 E 2 2 A1 E1 A3 E 3 96 EI 6 EI Also, R1 R2 R3 W (4) Taking moment of all the forces about F, we get 3 R1 .2 L W L R2 .L 0 2 R 3 (5) R1 W 2 4 2 Now solving Eq. (3), (4) and (5) we get the values of R1, R2 and R3. From Eq. (3) be substituting the values of R1' R2 and R3 from Eq. (4) and (5). R R 3 3 ( W 2 ) L (W R2 W 2 ) L R2 L 1 4 11 WL3 R2 L 2 4 2 A2 E 2 2 A1 E1 A3 E 3 96 EI 6 EI L L L L3 11 WL3 3 WL 1 WL R2 8 A1 E1 8 A3 E 3 A2 E 2 4 A1 E1 4 A3 E 3 6 EI 96 EI W 11 L3 3L L 8 12 EI A1 E1 A3 E 3 11 L3 3 K K 3 1 12 EI R2 2 L3 K 4 K K 2 3 1 3 EI W 2 Where, K 1 L L L , K2 , K3 A1 E1 A2 E 2 A3 E 3 11 L3 3 K K 3 1 12 EI 3 W R1 W 4 4 2 L3 K1 4K 2 K 3 3 EI 2 L3 11 L3 3 K 12 K 3 K 3 K 3 K K 2 3 1 1 2 1 EI 12 EI W 2 L 4 K 1 4 K 2 K 3 K 3 3 EI (6) 7 13 L3 12 K 2 K 2 3 12 EI W (7) 4 2 L3 K1 4K 2 K 3 3 EI and R3 = W- R1 - R2 13 L3 11 L3 12 K 2 K 3 K K 2 3 3 1 12 EI 12 EI W W W 4 2 L3 2 2 L3 K1 4K 2 K 3 K1 4K 2 K 3 3 EI 3 EI 8 L3 13 L3 11 L3 2 4 K 16 K 4 K 12 K 2 K 6 K 2 K 2 3 3 1 3 1 3 EI 12 EI 6 EI W 4 2 L3 K1 4K 2 K 3 3 EI 1 L3 2 K 1 4 K 2 4 EI W (8) 4 2 L3 K 1 4 K 2 K 3 3 EI Condition II When the upper end of the central suspension rod is attached to the centre of a similar elastic beam. This is achieved by removing the support at B, then beam AC will also deflect due to the load R2 applied at its center. Here the total deflection of point E relative to its original position as given by Eq. (3) is equal to the elongation of member BE+ the central deflection of beam ABC and Eq. (3) will modified to R L 11 WL3 R2 L3 R2 L R2 L3 1 R1 L (3A) 3 A2 E 2 6 EI 2 A1 E1 A3 E3 96 EI 6 EI Now solution of Eqs. (3A), (4) and (5) will yield the values of R1, R2 and R3. 11 L3 3K 1 K 3 12 EI W (9) R2 2 4 L3 K 1 4 K 2 K 3 3 EI 8 37 L3 12 K 2 2 K 3 12 EI W (10) R1 4 4 L3 K 1 4 K 2 K 3 3 EI 5 L 2K1 4K 2 W 12 EI and R3 (11) 4 4 L3 K 1 4 K 2 K 3 3 EI L Here, K for any spring is the extension of the spring per unit load. AE 2.0 OBJECTIVE: To calculate experimentally and theoretically the loads in the three suspension rods supporting an elastic beam with a concentrated load hung midway between two of the suspension rods under two conditions. 1. 2. When the suspension rods are attached at their upper ends to rigid supports. When upper end of the central suspension rod is attached to the centre of a similar elastic beam. 3.0 APPARATUS: Apparatus consists of a three parallel bar suspension system with elastic beam at their upper and lower ends. The upper ends of the two outer suspension rods are tied to a vertical wooden board while central suspension rod may be tied to the center of another elastic beam supported at two outer ends only. 4.0 SUGGESTED EXPERIMENTAL WORK: Step1: Tighten the screws at the top of the beam ABC for making the supports rigid to achieve Condition I. Load the beam DEF at the quarter point by 200gms to initialize the system. Now apply the loads in steps of 1kg up to 4.0kg and measure the extension of the springs for knowing the force in the member. Step2: Now release the middle screw so that the top beam ABC also becomes operative to achieve Condition II. Load the lower beam in the step of 1kg.up to 4kg and measure extension in the spring for calculating the forces. 5.0 RESULTS AND DISCUSSION: Compare the theoretical and experimental values of forces in various members in both cases. 9 6.0 SAMPLE DATA SHEET: Table-1 Observed value of reactions Load (kg) Reading at R2 (Reaction) R1 (Reaction) R3 (Reaction) Condition I Condition II Table-2 Comparison of Results Applied Load Condition I Condition II 7.0 R1 R2 R3 Remarks Observed Calculated Observed Calculated PRECAUTIONS: (a) (b) Increase the load on the spring gradually while finding the value of K of individual spring. Load the lower beam without any jerk.