Bed, hospital electrically actuated - use and maintenance of, SWP

advertisement

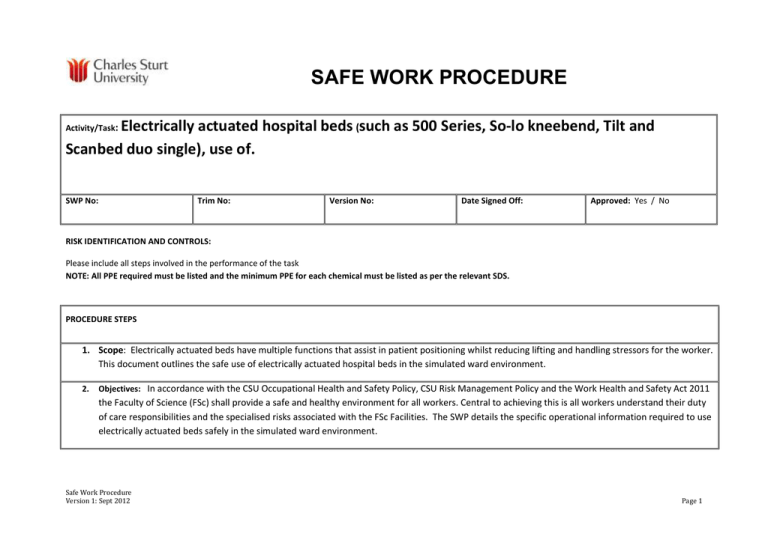

SAFE WORK PROCEDURE Electrically actuated hospital beds (such as 500 Series, So-lo kneebend, Tilt and Scanbed duo single), use of. Activity/Task: SWP No: Trim No: Version No: Date Signed Off: Approved: Yes / No RISK IDENTIFICATION AND CONTROLS: Please include all steps involved in the performance of the task NOTE: All PPE required must be listed and the minimum PPE for each chemical must be listed as per the relevant SDS. PROCEDURE STEPS 1. Scope: Electrically actuated beds have multiple functions that assist in patient positioning whilst reducing lifting and handling stressors for the worker. This document outlines the safe use of electrically actuated hospital beds in the simulated ward environment. 2. Objectives: In accordance with the CSU Occupational Health and Safety Policy, CSU Risk Management Policy and the Work Health and Safety Act 2011 the Faculty of Science (FSc) shall provide a safe and healthy environment for all workers. Central to achieving this is all workers understand their duty of care responsibilities and the specialised risks associated with the FSc Facilities. The SWP details the specific operational information required to use electrically actuated beds safely in the simulated ward environment. Safe Work Procedure Version 1: Sept 2012 Page 1 3. 4. References: Joyce Healthcare 500 Series User Manual SWP – movement of manikins. Timing: This SWP must be read prior to initial use of beds and accessed as required at all times when using the facilities where the beds are located. 5. Responsibilities: Workers - Academic Ensuring beds are used compliantly. Taking reasonable care for their and other workers health and safety. Requesting training if required. Developing risk assessments in accordance with the Risk Assessment Procedure. Reporting hazards, incidents and near misses in accordance with CSU OHS policy. Workers - Technical officer Ensuring beds are used compliantly. Taking reasonable care for their and other workers health and safety. Requesting training if required. Assisting in the developing risk assessments in accordance with the Risk Assessment Procedure. Reporting hazards, incidents and near misses in accordance with CSU OHS policy. Ensuring beds are ready for use, clean and maintained. Workers – Student Following the FSc laboratories and specialist teaching spaces student induction information. Safe Work Procedure Version 1: Sept 2012 Page 2 Complying with all safety directives and instructions from academic and technical staff. Following safe work practices when using the beds Taking reasonable care for their and other workers health and safety. Reporting hazards, incidents and near misses in accordance with CSU OHS policy. Workers - Outside organisations Following the FSc laboratories and specialist teaching spaces induction information. Complying with all safety directives and instructions from academic and/or technical staff. Following safe work practices when using the beds Taking reasonable care for their and other workers health and safety. Reporting hazards, incidents and near misses in accordance with CSU OHS policy. 6. In the event of: (emergency or other) – Follow specific facility guidelines and induction information. 7. Location: Building 666/204 – Albury Wodonga Campus. 8. Training Requirements: Induction to facilities where electrically actuated beds are located and step by step instruction and demonstration as per this SWP. 9. Plant and Equipment Details: 500 Series, So-lo kneebend, Safe Work Procedure Version 1: Sept 2012 Page 3 tilt scanbed duo single 10. Engineering Details, Certificates, Work Cover Approvals: 11. Maintenance Requirements: Preventative maintenance should be carried out at intervals of approximately 12 months. All service and repair activities must be carried out by approved, properly qualified and trained personnel. Safe Work Procedure Version 1: Sept 2012 Page 4 12. Task/Activity Steps: 1: The total safe working load for the bed is 200kg. Possible Hazards: Safety Controls: Putting too much weight onto the bed may cause damage to the bed, Ensure users are aware that maximum weight on the bed is financial loss related to damaged equipment, inability to deliver class 200kg. activities and/or physical injury to staff or students. Risk Score: 5 Bed brakes should be activated at all times to avoid potential injury. Ensure the brakes are on by pushing the two couple brake pedals at the foot of the bed from the horizontal free position to down. 2: Possible Hazards: Safety Controls: Risk Score: Damaged equipment, financial loss related to damaged equipment, inability to deliver class activities and/or physical injury to staff or students. Ensure users apply bed brakes when the bed is not being moved. 4 Connect the electrical power cable to a suitable socket outlet. The emergency back-up battery is automatically switched on if the bed is disconnected from the mains power supply. This will enable emergency power operation for short periods of time. 3: Possible Hazards: Safety Controls: Risk Score: Electric shock Ensure maintenance and testing and tagging is carried out 4 Safe Work Procedure Version 1: Sept 2012 Page 5 annually on the beds. Before operating the bed make sure the patient (manikin) is positioned correctly to avoid entrapment or imbalance 4: Possible Hazards: Safety Controls: Risk Score: Damaged equipment, financial loss related to damaged equipment, inability to deliver class activities and/or physical injury to staff or students. Ensure users are aware of this SWP and SWP for movement of manikins to avoid manual handling injuries. 4 The height, backrest angle and leg elevation functions are all power driven. When a handset push-button is pressed, the appropriate bed function will operate until the push button is released. 5: Possible Hazards: Damage to equipment. Financial loss related to damaged equipment, inability to deliver class activities and/or physical injury to staff or students. 6: Safety Controls: When the bed is operated make sure that obstacles such as bedside furniture do not restrict the movement of the bed. Risk Score: 4 Make sure that handsets and electrical power cables cannot become entangled with moving parts of the bed Possible Hazards: Damage to equipment. Financial loss related to Safety Controls: Risk Score: damaged equipment, inability to deliver class activities and/or physical injury to staff or students. Users to follow this SWP. 3 7: Safe Work Procedure Version 1: Sept 2012 Disconnect from the mains power supply before cleaning Page 6 Possible Hazards: Safety Controls: 4 Electric shock, damage to equipment. 8: Risk Score: Do not use the safety sides of the bed to lift or move it. Possible Hazards: Safety Controls: Risk Score: Manual handling injuries, damage to the bed. Follow this SWP. Move the bed using the bed head and end ensuring the brakes are off. 4 Safe Work Procedure Version 1: Sept 2012 Page 7 SAFE WORK PROCEDURE: Assessment dates Initial assessment date: 8/5/2013 Current assessment date: Reassessment due date: Assessors: Name: Amy Vaccaro Signature: Date: 8/5/13 Recommendation: (Technical Officer/Supervisor/Manager) Follow up required: Yes / No Name: Date: Signature: Approval: (Facility Manager, Head of School, Manager University Laboratories) Name: Safe Work Procedure Version 1: Sept 2012 Signature: Date: Page 8 Risk Assessment Matrix: Evaluate the level of risk associated with the hazard identified. SEVERITY LIKELIHOOD How severely could it hurt someone How likely is it to be that bad? or How ill could it make someone? !!!! Kill or cause permanent disability or ill health ++ + - -- Very likely Could happen at any time Likely Could happen sometime Unlikely Could happen, but very rarely Very unlikely Could happen, but probably never will 1 1 2 3 !!! Long term illness or serious injury 1 2 3 4 !! Medical attention and several days off work 2 3 4 5 ! First aid needed 3 4 5 6 Safe Work Procedure Version 1: Sept 2012 Page 9 I have read and understand this Safe Work Procedure: Name: Safe Work Procedure Version 1: Sept 2012 Position/Role: Signature: Date: Page 10