A Micro-Volume Viscosity Measurement Technique based on μPIV Diffusometry Han-Sheng Chuang

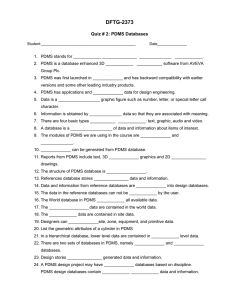

advertisement

A Micro-Volume Viscosity Measurement Technique based on μPIV Diffusometry Yue-Syun Sie1, Han-Sheng Chuang1,2, * 1 Department of Biomedical Engineering, National Cheng Kung University, Tainan, Taiwan. 2 Medical Device Innovation Center, National Cheng Kung University, Tainan, Taiwan. *oswaldchuang@mail.ncku.edu.tw Fabrication of the measurement chamber The measurement chamber was composed of a glass plate and a PDMS slab containing micro wells. A homogeneously dispersed particle suspension was reversibly sealed between the slab and the glass plate. The PDMS slab was prepared by mixing Sylgard 184 (Ellisworth Adhesives) with its cure agent in a ratio of 10:1, and then curing at room temperature for 24 hours. The PDMS wells were casted from a SU8 mold. The mold was fabricated with the conventional photolithography. Negative photoresist, SU8 2025 (Microchem Corp.), was utilized due to its robustness and appropriate viscosity for thick coating. The film thickness of the liquid channels was 40 μm based on a spinning speed of 1000 RPM. The coating was prebaked at 65 °C for 15 min and then exposed under UV light for 30s. Subsequently, the coating was post-baked at 65°C for another 20 min. After the SU8 was fully cross-linked, it was immersed in SU8 developer until the patterns were clearly formed. When the mold was fabricated, PDMS wells could be replicated repeatedly. As shown in Fig. S1, the preparation of particle suspension in a measurement chamber was depicted step by step. To ensure that the suspension was not affected by imbalanced pressure, the measurement should not be undertaken until the suspended particles stop collective motion. Fig S1. Preparation of particle suspension in a measurement chamber. Setup for the Study of Kinematics of C. elegans In Fig. S2a, a 3 by 4 PDMS chamber array was used to confine C. elegans. The device allows a simultaneous measurement of multiple worms, which facilitates parallel processing and prevents complicated image tracing of individual worm bodies. The micro wells were formed by casting PDMS on a SU8 mold. Each well measured 1 mm in diameter and 80 μm in depth. Synchronized worms were forklifted to droplets from an agar dish. To prevent evaporation, the drops were covered with an air-permeable, biocompatible mineral oil. A transparent cap was used to cover the well array to minimize potential disturbance from ambient airflow. Subsequently, the well array was then placed under an inverted microscope (CKX41, Olympus) for image recording. A low magnification objective (4×) was used to image all the wells simultaneously. The dimensions of the wells were carefully designed, so they all fitted within the same field of view. A high speed camera (GX3, NAC Image Technology USA) was mounted on the microscope and acquired images at a frequency of 100 Hz (Fig. S2b). During the course of the experiments, the room temperature was maintained at 25°C. Recording Images (a) (b) 4X Aqueous Droplet Mineral Oil H Petri Dish PDMS Substrate Worm Fig S2. (a) Schematic of the nematode imaging system. (b) An instantaneous image of worms caged in a 4×3 chamber array.