Cover Page for Lab Report – Group Portion

advertisement

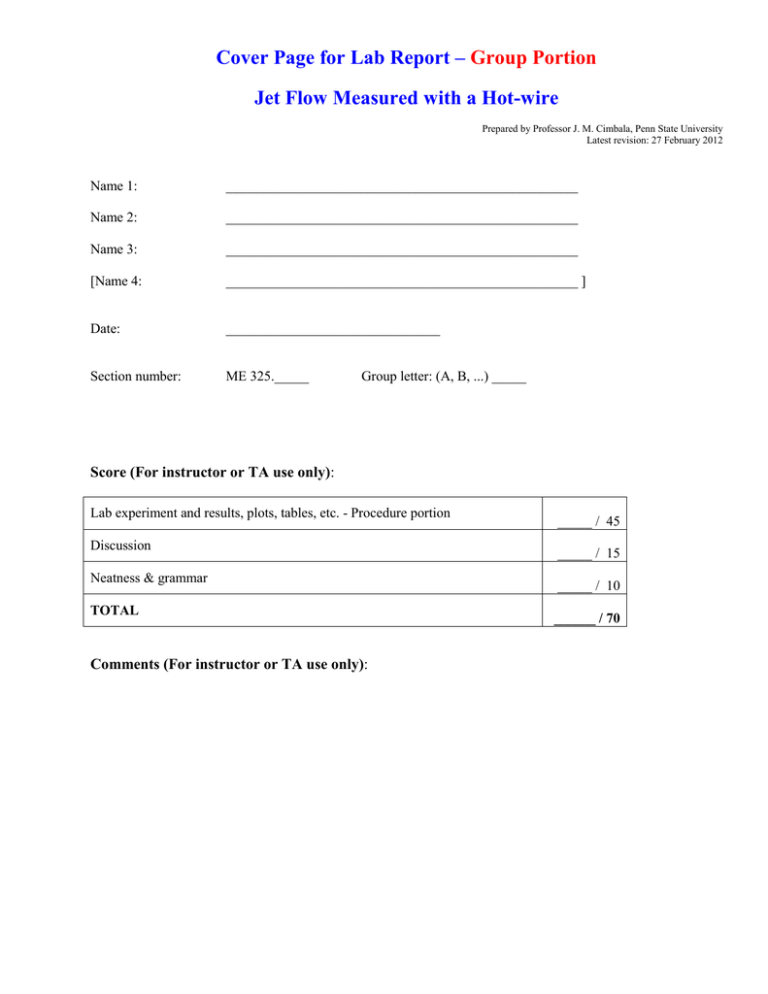

Cover Page for Lab Report – Group Portion Jet Flow Measured with a Hot-wire Prepared by Professor J. M. Cimbala, Penn State University Latest revision: 27 February 2012 Name 1: ___________________________________________________ Name 2: ___________________________________________________ Name 3: ___________________________________________________ [Name 4: ___________________________________________________ ] Date: _______________________________ Section number: ME 325._____ Group letter: (A, B, ...) _____ Score (For instructor or TA use only): Lab experiment and results, plots, tables, etc. - Procedure portion Discussion Neatness & grammar TOTAL Comments (For instructor or TA use only): _____ / 45 _____ / 15 _____ / 10 ______ / 70 Procedure A. Channel Assignments Before taking any data, note the assignments for the data acquisition channels: B. Channel 0: Channel 1: hot-wire voltage pressure difference (P0 – Patm) (see Figure 7) Patm Horizontal Traverse Orientation The jet assembly moves horizontally to enable a velocity profile to be measured across the jet. The horizontal movement is controlled by using two precision micrometers. The micrometers are aligned such that when both are set to 0.00 mm, the hot-wire is at approximately the center of the jet. For consistency, let the right micrometer will be negative, and let the left micrometer be positive (Figure 7). In other words, when the right micrometer reads 15.0 mm, and the left micrometer reads 0.00, the horizontal distance is taken as –15.0 mm. When the left micrometer reads 15.0 mm, and the right micrometer reads 0.00 mm, the horizontal distance is taken as +15.0 mm. P0 Air in Left micrometer r>0 C. Hot-wire Calibration Caution: Never turn the hot-wire anemometer on or off unless the anemometer is in the “STANDBY” mode. Failure to do so may fry the hot-wire. Right micrometer r=0 r<0 Figure 7. Sign convention for the horizontal micrometers. In order to measure velocity profiles across the jet, the hot-wire must first be calibrated as a function of air velocity U. Unfortunately, hot-wire voltage is not a linear function of velocity, so a higher-order curve fit is required. In this lab, a thirdorder polynomial curve fit is required. The general purpose data acquisition computer code is used for this calibration. 1. 2. (1) 3. If the anemometer power is on, leave it alone. If it is off, first turn the switch to “STANDBY” mode, then turn it on. Turn on the voltmeter, filter, oscilloscope, and pressure transducer display. Allow the instruments to warm up for a few minutes. Check all the cable connections (see Figure 2 of the Introduction). To prevent the hot wire from accidentally touching the jet nozzle, the tip of the hot-wire probe cannot go below about 1 cm above the jet exit plane. Never crank the vertical traverse below about 0.5 cm or it jams the traverse. Adjust the axial (x direction, vertical) traverse to 0.5 cm such that the hot-wire is about 1 cm above the jet exit plane. Adjust the horizontal traverses to the center of the jet exit plane (both horizontal micrometers at 0.00). By eye, estimate and record the approximate axial (vertical) distance from the hot-wire to the jet exit plane: xnear jet exit = 4. cm from the jet exit plane Make sure the jet is off by closing the Apollo main shut-off valve. With the Validyne transducer display unit set on the LO range, adjust the zero potentiometer to 0.000. Do not adjust the span potentiometer, as it is already calibrated. Namely, the Validyne pressure transducer measures the stagnation pressure in the jet, and displays this pressure in units of inches of water column. In standard SI units, 1 inch of water column = 249.09 N/m2 5. (2) 6. 7. With the anemometer still in the STANDBY mode, adjust, if necessary, the REF SET so that the meter on the anemometer reads 5.0 volts (needle nearly vertical), and the TSI hot-wire voltmeter reads 5.00 volts. Switch the anemometer to RUN BRIDGE OUTPUT. [Do not use RUN LINEAR OUTPUT.] Be sure that the TSI hot-wire voltmeter is set to DC VOLTS and is operating in the 10 volt range. The time constant can be either 0.1 or 1.0 seconds. If you choose the latter, the reading is more steady, but it takes a few seconds to stabilize. Note the voltage reading on the TSI hot-wire voltmeter. This is the minimum hot-wire voltage (at zero velocity), and should lie somewhere between 0 and 5.0 Volts. Record that value here. Minimum hot-wire voltage = 8. (2) 9. (1) volts Slowly open the Apollo main shut-off valve until it is fully open. Adjust the pressure regulator (if necessary) so that the pressure gauge reads 50 psi. Open the small, green pressure control valve until it is fully open. The stagnation pressure on the Validyne display should read about 1.7 volts (1.7 inches of water column). Note the reading on the TSI hot-wire voltmeter again. This is the maximum hot-wire voltage, and should not exceed 5.0 volts; otherwise clipping of the signal will occur. Maximum hot-wire voltage = Volts 10. In this hot-wire calibration, we are concerned only with Channel 0 (hot-wire voltage) and Channel 1 (pressure difference). From the Windows Desktop or from the Start > All Programs menu, start the generic data acquisition program called BasicDAQ. 11. Create a hot-wire calibration file, and set up the program to plot pressure difference (P0 – Patm) on the vertical axis versus hot-wire voltage on the horizontal axis. This will allow you to view the data points as they are collected. 12. Take data at various jet velocities varying from zero (no flow – green pressure control valve fully closed) to the maximum flow rate (green pressure control valve fully open). For now, ignore the message box that appears which allows you to Enter Input Parameters; click OK. Take enough data to generate a smooth curve fit. You will need especially fine increments at very low speeds. Change the axes on the graph as necessary to zoom in on the data. When you have enough data to generate a smooth curve, Quit. 13. Open your hot-wire calibration file in Notepad, and copy the data into Microsoft Excel. You may need to convert from text to data. 14. In Excel, create a new column for velocity, where U (5) (3) (2) Intercept = m/s X Variable 1 = (m/s) / volt X Variable 2 = (m/s) / volt2 X Variable 3 = (m/s) / volt3 17. Plot the calibration in the usual fashion (symbols only for measured data, line only for curve fit). Ask your instructor or TA to initial your calibration plot before continuing. Attach your hot-wire calibration plot to your report. . Measurement of mean velocity profiles 1. (2) Being careful of unit conversions, list U in units of m/s. (Assume that = 1.19 kg/m3 for air.) 15. To the right of the hot-wire voltage column (Chan. 0 volts), create columns for (Chan. 0 volts)2 and (Chan. 0 volts)3. These columns will be useful for regression analysis of the calibration data. Do not forget to include the hot-wire voltage for zero velocity obtained in step #7; otherwise, your curve fit equation will give erroneous velocity values at low voltages. 16. Perform a third-order regression analysis of U as a function of (Chan. 0 volts), (Chan. 0 volts)2, and (Chan. 0 volts)3. Note: The calibration is of velocity vs. hot-wire voltage, not the other way around. This is critical, because later, when you use the calibration curve fit, you will measure hot-wire voltage, and then use your calibration curve fit equation to calculate velocity. Write down the intercept and the three coefficients of the polynomial curve fit. These will be needed for the mean velocity profile measurements. See Figure D. 2 P0 Patm 2. Adjust the green pressure control valve so that the pressure difference (P0 – Patm) measured by the Validyne pressure transducer is 0.500 inches of water. Calculate the jet exit velocity for this pressure difference, showing all your work below. Uj = 3. 4. m/s You are now ready to begin the data acquisition. Start the BasicDAQ program again. Create an output file name indicative of this velocity profile, e.g. “profile_near_jet_exit_Smith_Jones_Group_C.txt”. Set up the program to plot the hot-wire voltage (Channel 0) on the vertical axis as a function of Radial Distance (Parameter 1) on the horizontal axis. Set the sampling rate to 2000 Hz, and set up the data acquisition system to record 5000 samples per channel. 5. 6. (5) 7. Take many data points across the jet as you adjust the horizontal micrometer between its limits (15 mm to 15 mm). At each point, manually enter value of the radial distance in the Parameter 1 box. Watch the oscilloscope trace – observe what happens when the hot-wire is in the shear layer of the jet. As you move across the top-hat portion of the jet, or outside the jet edge, it is not necessary to take data at extremely fine spacing. On the other hand, if you are taking data in the jet shear layer, where the velocity changes rapidly with a very small micrometer movement, you should take data at a fine spacing to adequately resolve the jet velocity profile in this region. Note: The sequence and spacing between r locations is not important. In other words, you can “back track” to fill in some data points if desired. You can sort the data later in Excel. Quit when you have a sufficiently resolved jet velocity profile. Plot the velocity profile using Microsoft Excel. In particular, plot mean measured velocity (m/s) as a function of radial distance r (mm). Note: You will need to use the regression analysis results from the hot-wire calibration. See Figure (5) 8. Repeat the measurements at an axial location of 2.0 cm on the vertical traverse. See Figure (5) 9. . Repeat the measurements at an axial location of 3.5 cm on the vertical traverse. See Figure (5) . . 10. Repeat the measurements at an axial location of 7.0 cm on the vertical traverse. See Figure . 11. Turn the hot-wire anemometer to STANDBY, and then shut off all electronic instruments. Presentations of Results (10) 1. For each of the three velocity profiles, integrate using the trapezoidal rule: Eq. (5) of the Precalculations to calculate mass flow rate, m . Hints: The centerline radial location r = 0 may need to be shifted first, since the horizontal micrometers are not necessarily aligned exactly at r = 0. (To shift r, locate the r value at the middle of the jet, and subtract this value from all the r values.) Also, make sure the radius and mass flow rate are always positive. (Positive radius can be achieved by using the absolute value of the radial distance in the trapezoidal rule.) The final summation of m will have to be divided by two, and as always, be very careful with units. Report your results here: m near jet exit = kg/s. m x=2.0 cm = kg/s. m x=3.5 cm = kg/s. m x=7.0 cm = kg/s. Attach a sample of the spreadsheet used to calculate m , using the trapezoidal rule. Be sure to list the equations that you used in the cells to calculate m . (You may do so either in the space below or on the spreadsheet itself.) See Table . Discussion (5) 1. Has the potential core of the jet completely disappeared by 2.0 cm downstream of the jet exit plane? By 3.5 cm? By 7.0 cm? Explain. (5) 2. Compare the velocity fluctuations observed on the oscilloscope when the hot-wire is in the potential core of the jet and when it is in the shear layer of the jet. Explain. (5) 3. Compare the mass flow rate at the four axial locations. Explain.