Six Sigma J0444 OPERATION MANAGEMENT Universitas Bina Nusantara

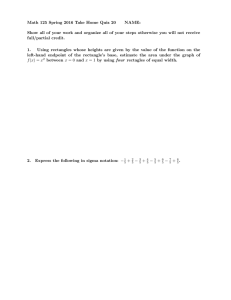

advertisement

J0444

OPERATION MANAGEMENT

Six Sigma

Universitas Bina Nusantara

History

• Carl Frederick Gauss (1777-1885) introduced the Normal Curve

concept.

• Walter Shewhart (1920): Six Sigma as a measurement standard in

product variation

• Bill Smith, an engineer from Motorola terminologized the “Six

Sigma”

• In the late 1970's, Mikel Harry, a senior engineer at Motorola's

Government Electronics Group (GEG), began to experiment with

problem solving through statistical analysis. Using his

methodology, GEG began to show dramatic results

• Dr. Mikel Harry and Richard Schroeder, were responsible for

creating the unique combination of change management and datadriven methodologies that transformed six sigma from a simple

quality measurement

Konsep Six Sigma

s

Metric

Benchmark

•

•

The “Sigma Value” is a Metric. It

Indicates How Well a Business

Process is Performing.

•

“Six Sigma” is a Philosophy Aimed at

Increasing the Sigma Value of All

Business Processes.

Philosophy

Tool

Symbol

Goal

Value

Used to Describe the Distribution of

Any Process.

•

Vision

Method

Letter in the Greek Alphabet.

What is Six Sigma

• Measure of Quality

• Process For Continuous

Improvement

• Enabler for Culture Change

Measure of Quality

Example #1: Manufacturing Steel Rolling

Mill

Sheet Thickness is a CTQ

(Critical to Quality Parameter)

Nominal Thickness = 1000 mm

Minimum Spec

= 950 mm

Maximum Spec

= 1050 mm

Scrap Production averages 100 meter / Coil

Measure of Quality

Lower

Specification

Limit

Scrap

Upper

Specification

Limit

Scrap

No Less Than

No More Than

950mm

1050mm

Steel Strip

Thickness

Quite some

Variation

-Ending up as

Scrap

Measure of Quality

Lower

Specification

Limit

Upper

Specification

Limit

Standard Deviation

Let’s Look at some

Basic Statistics

25mm

Mean Thickness = 993 mm

Standard Deviation = 25 mm

Mean Thickness

993mm

On Average it’s OK - it’s a Variation issue

Measure of Quality

Lower

Specification

Limit

Upper

Specification

Limit

Standard Deviation

25mm

How Capable is

our Process to

Produce within

Spec?

Sigma Rating = Spec Width / 2* SD

= 100 / 50

Spec Width (1050-950)

100mm

=

2

Measure of Quality

Lower

Specification

Limit

Upper

Specification

Limit

Reducing

Variation is

Clearly the Key to

Improving

Process

Spec Width

Capability

100 mm

Std Dev

25 mm

2s

Measure of Quality

Lower

Specification

Limit

Upper

Specification

Limit

Reducing

Variation is

Clearly the Key to

Improving

Process

Spec Width

Capability

100 mm

Std Dev

17 mm

3s

Measure of Quality

Lower

Specification

Limit

Upper

Specification

Limit

Reducing

Variation is

Clearly the Key to

Improving

Process

Spec Width

Capability

100 mm

Std Dev

12 mm

4s

Measure of Quality

Lower

Specification

Limit

Upper

Specification

Limit

Reducing

Variation is

Clearly the Key to

Improving

Process

Spec Width

Capability

100 mm

Std Dev

10 mm

5s

Measure of Quality

Lower

Specification

Limit

Upper

Specification

Limit

Reducing

Variation is

Clearly the Key to

Improving

Process

Spec Width

Capability

100 mm

Std Dev

8 mm

6s

Measure of Quality

Lower

Specification

Limit

Upper

Specification

Limit

6 Sigma Lingo

2s

Spec

Width

Spec

100

Standard

Deviation

25

Unit : Each Measurement

Sigma DPMO

Level

2

308,500

%

In

69.1

Defect : Measurement out of

Spec

Defect Opportunities per Unit :

1

Quality expressed as DPMO

( Defects per Million

Opportunities)

Measure of Quality

Lower

Specification

Limit

Upper

Specification

Limit

6 Sigma Lingo

3s

Spec

Width

Spec

100

100

Unit : Each Measurement

Standard Sigma

Deviation Level

DPMO

%

In

25

2

308,500

69.1

17

3

66,800

93.3

Defect : Measurement out of

Spec

Defect Opportunities per Unit :

1

Quality expressed as DPMO

( Defects per Million

Opportunities)

Measure of Quality

Lower

Specification

Limit

Upper

Specification

Limit

6 Sigma Lingo

4s

Spec

Width

Spec

100

Unit : Each Measurement

Standard Sigma

Deviation Level

DPMO

%

In

25

2

308,500

69.1

100

17

3

66,800

93.3

100

12

4

6,200

99.4

Defect : Measurement out of

Spec

Defect Opportunities per Unit :

1

Quality expressed as DPMO

( Defects per Million

Opportunities)

Measure of Quality

Lower

Specification

Limit

Upper

Specification

Limit

6 Sigma Lingo

5s

Spec

Width

Spec

100

Unit : Each Measurement

Standard Sigma

Deviation Level

DPMO

%

In

25

2

308,500

69.1

100

17

3

66,800

93.3

100

12

4

6,200

99.4

100

10

5

233

99.98

Defect : Measurement out of

Spec

Defect Opportunities per Unit :

1

Quality expressed as DPMO

( Defects per Million

Opportunities)

Measure of Quality

Lower

Specification

Limit

Upper

Specification

Limit

6 Sigma Lingo

6s

Spec

Width

Spec

100

Unit : Each Measurement

Standard Sigma

Deviation Level

DPMO

%

In

25

2

308,500

69.1

100

17

3

66,800

93.3

100

12

4

6,200

99.4

100

10

5

233

8

6

3

100

99.9997

99.98

Defect : Measurement out of

Spec

Defect Opportunities per Unit :

1

Quality expressed as DPMO

( Defects per Million

Opportunities)

Measure of Quality

Example #2: Product Delivery

PT X deliver their products to it’s customer

five times, their delivery time data are

PT Y deliver their products to it’s customer

five times, their delivery time data are

•21 days,

•14 days,

•15 days,

•12 days,

•12 days,

•12 days,

•10 days, and

•12 days, and

•2 days.

•10 days.

The AVERAGE (Mean) of Their Delivery

Time is:

21 + 15 + 12 + 10 + 2 = 60/5 = 12 DAYS

The AVERAGE (Mean) of Their Delivery

Time is:

14 + 12 + 12 + 12 + 10 = 60/5 = 12 DAYS

Measure of Quality

PT X The AVERAGE (Mean) of Their

Delivery Time is: 12

DAYS

Lower

Specification

Limit

Upper

Specification

Limit

But…

Standard Deviation = 7.0

PT Y The AVERAGE (Mean) of Their

Delivery Time is: 12

DAYS

And….

Standard Deviation = 1.4

Lower

Specification

Limit

Upper

Specification

Limit

Measure of Quality

Baseline Improved (?)

12

24

14

7

16

8

20

25

14

10

11

30

16

Mean 15.8

27

7

15

4

18

6

23

6

2

24

2

6

5

Example #2: Service Time

• Using mean-based thinking, we improve

average performance by 29%, and break

out the champagne…..

• BUT….our customer only feels the

VARIANCE,….and cancel the next orders!

What the Company Feels

11.2

11.2

SD

7.0

9.0

15.8

What Customer Feel

Measure of Quality

Improved (?)

11

11

10

10

12

11

11

11

11

12

12

12

10

Mean 11.07

SD

0.76

• Now it is improved….the Mean is 11,

and the STD is below 1….

• but UNFORTUNATELY, what the

customer wants is 9 days (or what

competitors can do is 9 days)….so it

is not variance issue anymore, but

now about the Process Centering

issue

Variation is the enemy!

• Variation reduction = Defect

reduction

• Quality measurement =

measurement of defect on the

process/products

• Six Sigma process = Defect

reduction until 3.14 out of 1 Million

products/process

23

Variation Reduction

A Process is

“A Distribution of Distributions”

Goal: Reduce Process Width-Variation is the Enemy

24

The Athletic View of

Performance

• Consider a goalkeeper who

plays 50 games a year and

faces 40 shots on goal each

game.

• A defect is when the

opposition scores.

• A 6s goalkeeper will be scored

against once in every 147 years

25

Is 6 Sigma Impossible?

• US airline baggage handling: 30-50,000 lost items per million, ~ 3 3.5s

• Average Companies: 30-50,000 defects per million ~ 3 - 3.5s

• World-Class Companies: <1000 defects per million 5 - 5.5s

US airline

fatality rate:

< ½ per million flights, > 6s

Process for

Continuous

Improvement

Nature Of The Problem

Off-Target

XX

XX

X

X

X

XX

Center

Process

On-Target

Variation

X X

X X

X X

X

XX X

X

X

XXX

X

X

X

XXX

X

Reduce

Spread

Process for Continuous

Improvement

Y = f {X1, X2, X3, …Xn}

Output

(Dependent

Variable)

Process

(Independent Variables)

Identifying Variation

Sources

X3

X1

Process

X4

X2

Xn-2

Xn-1

OUTPUT

Y

Xn

Y = f ( X1, X2, X3, X4, … , Xn-2, Xn-1, Xn)

Inside the Box Xs

Controllable

Outside the Box Xs

Un-Controllable

29

Six Sigma

approach is

focus on

process…

Fixing process so they

will produce perfection

on products and services

Define

Measure

Analyze

Six Sigma

Methodology

DMAIC

For improve existing process/products

Improve

Control

Define

Measure

Analyze

Design

Verify

Six Sigma

Methodology

DMADV

For new process/products

(sometime called DFSS,

Design For Six Sigma)

Define Phase

• Voice of Customer (VOC)?

• Problems?

• Unit, Defects, Opportunities?

33

Measure Phase

•

•

•

•

Collect data baseline

Identify frequency of defects?

Baseline process capability?

Target or benchmark process capability?

34

Analyze Phase

•

•

•

•

Why, when, where defects occurs?

Data analysis

Process analysis

Identify Vital X’s

35

Improve Phase

• How to reduce defects?

• Fix problems

• Collect improved data

36

Control Phase

• Calculate new process capability

• Verify statistically improvement made

• Implement process control

37

The 6 Sigma Success Factors

Business Process

Framework

Quantifiable

Measures &

Results

Establishing these factors

provides the seeds of

success.

Six Sigma

Projects

Incentives &

Accountability

Committed and

Involved

Leadership

Full Time 6 Sigma

Team Leaders

They need to be integrated

consistently to fit each

business.

They are all necessary for the

best result

Strategy

Integration

The most powerful success

factor is “committed

leadership.”

What Is Six Sigma

Projects?

• Project needs to be done by Every Employee (Green Belt)

• Project using Six Sigma methodology (DMAIC/DMADV)

• Project that making Improvement (DPMO reduction)

• Project that has a measurable unit and defect

• Project that has a measurable impact

• Project that start with Customer (internal/external) CTQ

Harvesting the Fruit of Six

Sigma

Start With Low Hanging Fruit

Sweet Fruit - 6s

Design for Six Sigma (DFSS)

Process Entitlement

Bulk of Fruit - 4 to 5s

Process Improvement

Six Sigma Tools

Low Hanging Fruit - 3 to 4s

Basic Quality Tools

Ground Fruit - up to 2s

Logic and Intuition