Low Speed LP

advertisement

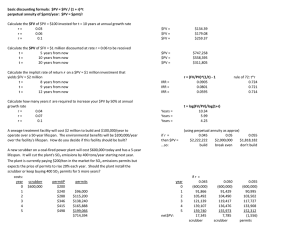

Equipment Low Speed Floor Polisher/ Scrubber (CFP 200) LESSON PLAN COURSE TITLE: Custodian CLASS TITLE: Equipment MODULE TITLE: Low Speed Floor Polisher/Scrubber (Side by Side) PROGRAM OVERVIEW: This block of instruction will provide the student with a basic knowledge of the proper operating procedures for the Low Speed Floor Scrubber (CFP 200). PARAMETERS Credit Hours: Date: 1(hr) Number of Participants: Target Audience: New Employees Required Training Space: Training Classroom Floor PERFORMANCE OBJECTIVES At the conclusion of this lesson, participants will: 1. The student will be able to properly operate the Low Speed Floor Scrubber in accordance to the manufactures directions per the Operators Manual EVALUATION TECHNIQUE Evaluation techniques utilized by the trainer(s) to determine if the performance objectives have been met. 1. Practical Demonstration 2. Question and Answer REQUIRED MATERIALS/EQUIPMENT/SUPPLIES/NEEDED 1 Low Speed Floor Polisher/ Scrubber 1 Scrubbing Pad 1 Large indoor space 1 VCR/DVD Player 1 Custodial Procedures Manual(Equipment) 1 Clarke CFP Operators Manual Videotapes: (1) Buckeye Routine Cleaning DVD Other: STUDENT HANDOUTS Title: Custodial Procedure Manual (Equipment, Clarke CFP 200) Clarke Operators Manual 1 Projector Screen N/A 1 N/A N/A Computer & LCD Television(s) Video Camera Masking Tape N/A Easel Pads & Stands INSTRUCTIONAL STRATEGIES Discussion, Practical Demonstration, Hands on Equipment REFERENCE(S) The following books and / or materials were used as a basis for this lesson plan. The instructor should be familiar with the material in these reference documents to effectively present this module. TITLE TITLE 1. Buckeye Honors Program 4. 2. Clarke CFP Operators Manual 5. 3. 6. Prerequisite Training/Certification: None Curriculum Prepared by: Ivan E. Wilson Sr. Curriculum Content Approved by: Date Approved Curriculum Design Approved by: Date Approved Original/Revision Date Original Date: 22 March 2010 Revision Date: Revision Date: Design Notes: Title: Low Speed Floor Polisher/Scrubber (CFP200) Trainer Notes 1. Description- The Low speed floor polisher/scrubber uses low speed revolutions to scrub floors. This machine is often referred to as a side by side because of the side to side scrubbing action. 2. Safety- Electric shock is always a concern when operating any electrical equipment near or around water. (a) Always read the operators manual before operating the machine (b) Do not operate the machine near children or small animals (c) Secure all lose items such as hair, watches, and clothing (d) Do not operate the machine if you have not been properly trained (e) Inspect the machine before and after every use (f) Use only approved chemicals 3. Machine Controls and Functions (Refer to the Operators Manual) (a) Operator hand grips- controls the machine (b) Switch Lever Safety Lock Button- Machine will not operate unless this is pressed along with the switch levers (c) Handle Release Compression Lever- unlocks the handle (d) Power Cord- source of electricity (e) Cord Hook- Used for storing the cord (f) Lugs- Holds the pad holder in place (g) Lug slots- Where the lugs insert into the holder 4. Operating the Side by Side (a) Inspect the machine before use. (b) Install the pad before operating the machine (c) Install the pad holder by placing it over the lugs and turning the holder until it locks in place (d) Unwrap the electric cord and plug into a properly ground outlet (e) Use a black pad for stripping and a tan or white pad for buffing Title: Low Speed Floor Polisher/Scrubber (CFP200) Trainer Notes *Caution* Be prepared to control the machine as soon as the motor starts. Just a slight movement up or down will cause the machine to move from side to side. Lift the handle to move the machine to the right, lower the handle to move the machine to the left. Do not attempt to push the machine, let it do the work for you. Keep the machine moving. Do not stay in one spot. Staying in one spot may damage the surface. (f) Hold one of the operator grips (g) Release the handle lock and lower handle to about waist level (lock handle) (h) Firmly, push the Safety Lock Button (i) Compress the Switch Levers (j) Slightly raise and lower the handle to cause the machine to move from side to side (Do not operate the machine without locking the handle in place) (k) Release the levers to stop the machine 5. Completing Scrubbing (a) Put the handle in the upright (b) Unplug electric cord and wrap it around handle and cord hook (c) Remove the pad or brush and clean it (d) Never store the machine with the pad attached (e) Clean and inspect the machine after use (f) Store the machine in a clean dry place with operator handle locked in the up right position Title: Low Speed Floor Polisher/Scrubber (CFP200) Trainer Notes Conclusion (a) The Low speed Floor Polisher/Scrubber is used for stripping floor wax. It is also known as the side by side floor stripper (b) Always inspect machine before and after use (c) Always read the operators manual (d) Be familiar with operators switches (e) Attach the pad holder by placing holder onto the lugs and turning until locked (f) Push the pad onto the holder (g) Move handle to about waist level before operating the machine and lock the handle in place (h) Push the Safety Lock Button while squeezing the switch lever to operate the machine (i) Be prepared to control the machine, the slightest movement up or down will cause the machine to move left or right (j) Do not stay in one spot for a prolonged time, this could damage the surface (k) Move the handle up to move to the right, move the handle down to move to the left (l) Use only approved chemicals (m) Inspect and clean the machine upon completion (n) Store in a clean dry place Introduction (1min) Low Speed Floor Polisher/Scrubber (CFP 200) Stripping floors are tough, The Clarke Low Speed Floor Polisher/ Scrubber (CFP) or Side by Side makes the job a little easier. The side by side is designed to use low speed revolutions and the weight of the machine to scrub a surface. We can strip floors completely or top scrub. Using the correct chemicals and techniques will make the tough job of floor stripping that much easier. Let’s take a look at this machine.