Manufacturing Facility Layout Slide 0 of 96

Manufacturing Facility Layout

Slide 0 of 96

Basic Layout Forms

• Process

• Product

• Cellular

• Fixed position

• Hybrid

Slide 1 of 96

Sistem produksi Intermitten

Lay out by process

Saw Grind Paint

Mill

Lathe

Drill

Slide 2 of 96

L

L

L

Tata Letak Proses

(Manufacturing Process Layout)

L

L

L

L L

L L

Lathe Department

M M

M M

Milling

Department

G G

G G

Grinding

Department

Receiving and

Shipping

G

G

D

D

D D D

D D D

Drilling Department

P

P

Painting Department

Assembly

A A A

Slide 3 of 96

Sistem produksi Continous

Lay out by product

Saw

Saw

Grind

Weld

Lathe

Mill

Mill

Grind

Mill

Drill

Drill

Lathe

Drill

Paint

Paint

Drill

Slide 4 of 96

Process (Job Shop) Layouts

• Equipment that perform similar processes are grouped together

• Used when the operations system must handle a wide variety of products in relatively small volumes (i.e., flexibility is necessary)

Slide 5 of 96

Characteristics of Process

Layouts

• General-purpose equipment is used

• Changeover is rapid

• Material flow is intermittent

• Material handling equipment is flexible

• Operators are highly skilled

• . . . more

Slide 6 of 96

Characteristics of Process

Layouts

• Technical supervision is required

• Planning, scheduling and controlling functions are challenging

• Production time is relatively long

• In-process inventory is relatively high

Slide 7 of 96

Product (Assembly Line)

Layouts

• Operations are arranged in the sequence required to make the product

• Used when the operations system must handle a narrow variety of products in relatively high volumes

• Operations and personnel are dedicated to producing one or a small number of products

Slide 8 of 96

Characteristics of Product

Layouts

• Special-purpose equipment are used

• Changeover is expensive and lengthy

• Material flow approaches continuous

• Material handling equipment is fixed

• Operators need not be as skilled

• . . . more

Slide 9 of 96

Characteristics of Product

Layouts

• Little direct supervision is required

• Planning, scheduling and controlling functions are relatively straight-forward

• Production time for a unit is relatively short

• In-process inventory is relatively low

Slide 10 of 96

Product Layout-

Advantages/Disadvantages

Advantages:

Disadvantages:

Low cost variable cost

High volume required per unit because of large

Lower material initial investment handling costs

Lack of flexibility in

reduction in work inhandling variety of process inventories products or

easier training and production rates supervision

Slide 11 of 96

L

L

L

Tata Letak Proses

(Manufacturing Process Layout)

L

L

L

L L

L L

Lathe Department

M M

M M

Milling

Department

G G

G G

Grinding

Department

Receiving and

Shipping

G

G

D

D

D D D

D D D

Drilling Department

P

P

Painting Department

Assembly

A A A

Slide 12 of 96

Part Routing Matrix

Reordered To Highlight Cells

PARTS

A

D

F

C

G

B

H

E

MACHINES

1 2 4 8 10 3 6 9 5 7 11 12 x x x x x x x x x x x x x x x x x x x x x x x x x x x x x

Slide 13 of 96

Cellular Layout Solution

4 Cell1

2

8 10

Assembly

9

Raw materials

1

Cell 2

A

6

3

C B

12

Cell 3

11

7

5

Slide 14 of 96

Designing and Analyzing a

Product Layout

• Line Balancing

Slide 15 of 96

Designing and Analyzing a

Product Layout

• Characteristics

• Inputs

• Design Procedure

• How Good Is The Layout?

Slide 16 of 96

Line Balancing Problem

• Work stations are arranged so that the output of one is an input to the next, i.e., a series connection

• Layout design involves assigning one or more of the tasks required to make a product to work stations

• . . . more

Slide 17 of 96

Line Balancing Problem

• The objective is to assign tasks to minimize the workers’ idle time, therefore idle time costs, and meet the required production rate for the line

• In a perfectly balanced line, all workers would complete their assigned tasks at the same time (assuming they start their work simultaneously)

• This would result in no idle time

• . . . more

Slide 18 of 96

Inputs

• The production rate required from the product layout or the cycle time.

– The cycle time is the reciprocal of the production rate and visa versa

• All of the tasks required to make the product

– It is assumed that these tasks can not be divided further

• . . . more

Slide 19 of 96

Inputs

• The estimated time to do each task

• The precedence relationships between the tasks

– These relationships are determined by the technical constraints imposed by the product

– These relationships are displayed as a network known as a precedence diagram

Slide 20 of 96

Design Procedure

1.

If not provided, find the cycle time for the line.

Remember the cycle time is the reciprocal of the production rate. Make sure the cycle time is expressed in the same time units as the estimated task times.

2.

Select the line-balancing heuristic that may be used to help with the assignments. (Two heuristics are described at the end of this procedure.)

. . . more

Slide 21 of 96

Design Procedure

3.

Open a new work station with the full cycle time remaining.

4.

Determine which tasks are feasible, i.e., can be assigned to this work station at this time. For a task to be feasible, two conditions must be met:

– All tasks that precede that task must have already been assigned

– The estimated task time must be less than or equal to the remaining cycle time for that work station.

Slide 22 of 96

Line-Balancing Heuristics

• Heuristic methods, based on simple rules, have been used to develop very good, not optimal, solutions to line balancing problems.

Slide 23 of 96

How Good Is the Design?

• Utilization is one way of objectively determining how near perfectly balanced an assignment scheme is.

• Utilization is the percentage of time that a ons x 100 ons

Sum of all task time s x 100

(Cycle Time) x (Actual number of work stations) or

Slide 24 of 96

Why is Balancing the Line

Important?

Min/

Unit

Station 1

6

Station 2

7

What’s Going to Happen?

Station 3

3

Slide 25 of 96

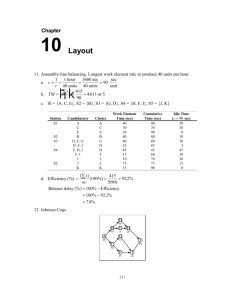

Example 1: The ALB Problem

• You’ve just been assigned the job a setting up an electric fan assembly line with the following tasks:

Task Time (Mins) Description

A 2 Assemble frame

B

C

1

3.25

Mount switch

Assemble motor housing

D

E

F

G

H

1.2

0.5

1

1

1.4

Mount motor housing in frame

Attach blade

Assemble and attach safety grill

Attach cord

Test

Predecessors

None

A

None

A, C

D

E

B

F, G

Slide 26 of 96

Example 1: The ALB Problem

The Precedence Diagram

• Which process step defines the maximum rate of production?

2

A

1

B

1

G

1.4

H

C

3.25

D

1.2

E

.5

F

1

Slide 27 of 96

Example 1: The ALB Problem

We want to assemble 100 fans per day

Production time per period

Required Cycle Time, C =

Required output per period

420 mins / day

C =

100 units / day

= 4.2 mins / unit

What do these numbers this represent?

Slide 29 of 96

Example 1: The ALB Problem

We want to assemble 100 fans per day

Theoretical Min. Number of Workstations, N t

N = t

Sum of task times (T)

Cycle time (C)

N = t

11.35 mins / unit

4.2 mins / unit

= 2.702, or 3

Why should we always round up?

Slide 30 of 96

Example 1: The ALB Problem

Selected Task Selection Rules

• Primary: Assign tasks in order the the largest number of following tasks.

• Secondary (tie-breaking): Assign tasks in order of the longest operating time

Slide 31 of 96

Example 1: The ALB Problem

Selected Task Selection Rules

Precedence Diagram

2

A

1

B

1

G

1.4

H

C

3.25

D

1.2

E

.5

F

1

Slide 32 of 96

2

A

C

3.25

1

B

1

G

D

1.2

E

.5

Station 1

F

1

1.4

H

Station 2

Task

A

C

D

B

E

F

G

H

Followers Time (Min)

6

4

2

3.25

3

2

2

1

1

0

1.2

1

0.5

1

1

1.4

Station 3

Slide 33 of 96

2

A

C

3.25

1

B

1

G

D

1.2

E

.5

F

1

1.4

H

Station 2

Task

A

C

D

B

E

F

G

H

Followers Time (Min)

6

4

2

3.25

3

2

2

1

1

0

1.2

1

0.5

1

1

1.4

Station 3 Station 1

A (4.2-2=2.2)

Slide 34 of 96

2

A

C

3.25

1

B

1

G

D

1.2

E

.5

F

1

1.4

H

Station 2

Task

A

C

D

B

E

F

G

H

Followers Time (Min)

6

4

2

3.25

3

2

2

1

1

0

1.2

1

0.5

1

1

1.4

Station 3 Station 1

A (4.2-2=2.2)

B (2.2-1=1.2)

Slide 35 of 96

2

A

C

3.25

1

B

1

G

D

1.2

E

.5

F

1

1.4

H

Station 2

Task

A

C

D

B

E

F

G

H

Followers Time (Min)

6

4

2

3.25

3

2

2

1

1

0

1.2

1

0.5

1

1

1.4

Station 3 Station 1

A (4.2-2=2.2)

B (2.2-1=1.2)

G (1.2-1= .2)

Idle= .2

Slide 36 of 96

2

A

C

3.25

1

B

1

G

D

1.2

E

.5

Station 1

A (4.2-2=2.2)

B (2.2-1=1.2)

G (1.2-1= .2)

Idle= .2

F

1

1.4

H

Station 2

Task

A

C

D

B

E

F

G

H

C (4.2-3.25)=.95

Followers Time (Min)

6

4

2

3.25

3

2

2

1

1

0

1.2

1

0.5

1

1

1.4

Station 3

Idle = .95

Slide 37 of 96

2

A

C

3.25

1

B

1

G

D

1.2

E

.5

Station 1

A (4.2-2=2.2)

B (2.2-1=1.2)

G (1.2-1= .2)

Idle= .2

F

1

1.4

H

Station 2

Task

A

C

D

B

E

F

G

H

C (4.2-3.25)=.95

Followers Time (Min)

6

4

2

3.25

3

2

2

1

1

0

1.2

1

0.5

1

1

1.4

Station 3

D (4.2-1.2)=3

Idle = .95

Slide 38 of 96

2

A

C

3.25

1

B

1

G

D

1.2

E

.5

Station 1

A (4.2-2=2.2)

B (2.2-1=1.2)

G (1.2-1= .2)

Idle= .2

F

1

1.4

H

Station 2

Task

A

C

D

B

E

F

G

H

C (4.2-3.25)=.95

Followers Time (Min)

6

4

2

3.25

3

2

2

1

1

0

1.2

1

0.5

1

1

1.4

Station 3

D (4.2-1.2)=3

E (3-.5)=2.5

Idle = .95

Slide 39 of 96

2

A

C

3.25

1

B

1

G

D

1.2

E

.5

Station 1

A (4.2-2=2.2)

B (2.2-1=1.2)

G (1.2-1= .2)

Idle= .2

F

1

1.4

H

Station 2

Task

A

C

D

B

E

F

G

H

C (4.2-3.25)=.95

Followers Time (Min)

6

4

2

3.25

3

2

2

1

1

0

1.2

1

0.5

1

1

1.4

Station 3

D (4.2-1.2)=3

E (3-.5)=2.5

F (2.5-1)=1.5

Idle = .95

Slide 40 of 96

2

A

C

3.25

1

B

1

G

D

1.2

E

.5

Station 1

A (4.2-2=2.2)

B (2.2-1=1.2)

G (1.2-1= .2)

Idle=.2

F

1

1.4

H

Station 2

Task

A

C

D

B

E

F

G

H

C (4.2-3.25)=.95

Followers Time (Min)

6 2

4

3

2

3.25

1.2

1

2

1

1

0

0.5

1

1

1.4

Station 3

D (4.2-1.2)=3

E (3-.5)=2.5

F (2.5-1)=1.5

H (1.5-1.4)=.1

Idle=.95

Idle=.1

Slide 41 of 96

Example 1: The ALB Problem

•

Which station is the bottleneck?

•

What is the effective cycle time?

Sum of task times (T)

Efficiency =

Actual number of workstations (Na) x Cycle time (C)

11.35 mins / unit

Efficiency =

(3)(4.2mins / unit)

=.

901

Slide 42 of 96