COSYSMO Application At BAE Systems Gan Wang COSYSMO USC Campus, Los Angeles, CA

advertisement

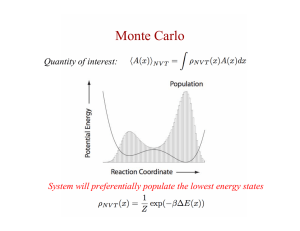

COSYSMO Application At BAE Systems Gan Wang COSYSMO Workshop 23rd International Forum on COCOMO and Systems/Software Cost Modeling and ICM Workshop USC Campus, Los Angeles, CA Oct. 29 & 30, 2008 ©2006 BAE Systems. COSYSMO Implementation at BAE Systems • Developed System Engineering Estimation Model and Process (SEEMaP) – Estimating end-to-end, system engineering and integration effort in a system development program – Company-wide, common estimating tool deployed across major sites, lines of business (LoBs) and operating groups (OGs), including New Hampshire, San Diego, New Jersey, New York… SEEMaP Workbook: Encapsulating Tool and Process • Desktop tool, calibrated with historical program data across LoBs – With organization and product line-specific calibrations • Applied to – ROM estimates – Engineering bid & proposal – Trade studies 2 Early Results Excellent • Deployed in 2007-2008 to E&IS OG – Applied to: ROM, bid & proposal, risk analysis – Mandated use by several organizations • Outstanding correlation achieved between estimate and actual in calibrations • Early experience shows excellent result: – Variance with other methods (bottom-up): 2–25% – Effort to create estimate: 2-8 hours SEEMaP (COSYSMO) Calibration – Cost saving and cycle time reduction: 85–95% – (Bottom-up may take up to weeks) 3 Quantitative Risk Analysis • COSYSMO provides single-point estimates – With fixed driver counts and classification Sizing Parameters Degrees of Reuse and Difficulties • Integrating Crystal Ball quantifies the uncertainty and provides quantitative risk analysis through Monte Carlo Simulation – Crystal Ball will provide a quantified output range of the various scenarios, with a probability of occurrence – A sensitivity analysis provides insight into which inputs most effect the outcome • Now it is possible to offer (true) 50/50, 80/20, 20/80 risk positions – Not just to claim them 4 Monte Carlo Simulation Generates an Estimate Distribution Input Distribution Monte Carlo Simulation 5 In the Works • Total Engineering Estimation Model and Process (TEEMaP) – Extending SEEMaP & COSYSMO capabilities to total engineering – Estimating the total, end-to-end engineering effort in development a system – Deployment in 2009 • Apply to company LCM Framework Validate contract pricing & quick trades for scope negotiation Prepare Proposal 1B Milestone Reviews 2A 2B Initial Design 2C 3A 3B System Qualification 4 5 In-Field Support Prepare Bid/No Bid Information TEEMaP Integration of System Phase Reviews Mobilize TEEMaP TEEMaP Contract Accepted TEEMaP Evaluate technology insertion, upgrades, & new opportunities Production, Installation and Commissioning Develop cost targets & validation of total/functional engineering bids Design System ROM to determine Cost & Risk positions relative to PTW 6 Disposal 7 TEEMaP Develop engineering baselines and milestone reviews & ETCs SRR CDR SDR/PDR PRR TRR 6 Questions and Comments Gan Wang gan.wang@baesystems.com 703-668-4259 7