Resurfacing

advertisement

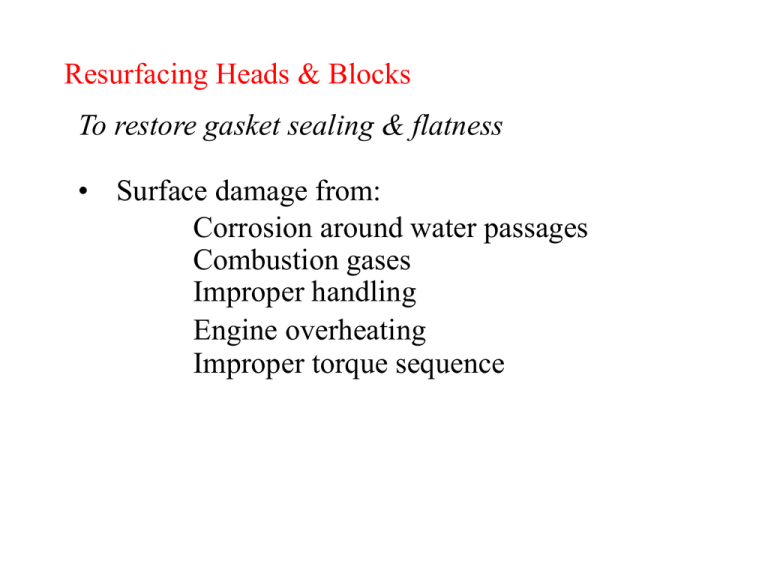

Resurfacing Heads & Blocks To restore gasket sealing & flatness • Surface damage from: Corrosion around water passages Combustion gases Improper handling Engine overheating Improper torque sequence Copyright 2003 Gary Lewis – Dave Capitolo Resurfacing Heads & Blocks Surfacing complications • OHV in-line engines Valve clearance with non-adjustable rockers Valve-to-piston clearance Possible detonation, higher compression ratios Resurfacing Heads & Blocks Surfacing complications • OHC in-line engines Possible detonation, higher compression ratios Retarded valve timing – About 1° per .020” Piston-to-valve clearance Install timing cover before surfacing Resurfacing Heads & Blocks Surfacing complications • OHV V-block engines Valve clearance with non-adjustable rockers Valve-to-piston clearance Possible detonation, higher compression ratios Intake manifold alignment - Oil consumption - Vacuum leaks Resurfacing Heads & Blocks Compression ratio changes • High vs. Low compression ratios Octane requirements increase with compression Emissions & power increase with compression Detonation chances increase with compression Resurfacing Heads & Blocks Surfacing machines • Sanding Quick Less precise Good for quick clean-up of exhaust manifolds Difficult to maintain precision Resurfacing Heads & Blocks Surfacing machines • Grinding Uses abrasive stones Can cut through hard material Good surface finish is possible Final passes are ‘sparked out’ Resurfacing Heads & Blocks Surfacing machines • Grinding (cont.) For Aluminum . . . Take shallow cuts Dress stone often Use soap on stone Resurfacing Heads & Blocks Surfacing machines • Milling Carbide generally for Aluminum CBN generally for Iron With good setup, heavy cuts are possible Hard spots dull cutters Resurfacing Heads & Blocks Surfacing machines • MLS gasket preparation Surface finish – 20 AA micro-inches Light cuts with slow feed rates Sharp cutters with lubrication Dress stones often Resurfacing Heads & Blocks Stock removal • • • • • Generally as little as possible (.020” total) Specs may not be available When available, specs = min thickness or max removal Some composite gaskets compensate for .010” Stock removal may exceed measured warp Resurfacing Heads & Blocks OHC head surfacing • Chain driven engines need timing cover installed • Top side can be surfaced for cam alignment • Use shims to restore cam height Resurfacing Heads & Blocks Diesel head surfacing • • • • Surface with pre-combustion chambers in place Chambers may be difficult to machine Measure valve recession on tear down Restore valve recession by grinding seats Resurfacing Heads & Blocks Air cooled head surfacing • • • • Sealing surface is inside chamber Seal surface is machined Inside diameter of surface may be contoured Surface deck to restore seal depth Resurfacing Heads & Blocks Resurfacing blocks • To maintain parallelism to crankshaft • Provide a better seal • Match deck heights on V-blocks Resurfacing Heads & Blocks Manifold alignment on V-blocks • Correction for port alignment • Correction for gasket crush Resurfacing Heads & Blocks Manifold alignment on V-blocks • Distributors can be shimmed to prevent intermediate shaft binding Resurfacing Heads & Blocks Determining ratios • Determine angle between cylinders • Determine angle of cylinder head Resurfacing Heads & Blocks Determining ratios • For port alignment, surface . . . Intake side of head, or Intake side of manifold