Project ASD (Aerial Surveillance Drone)

advertisement

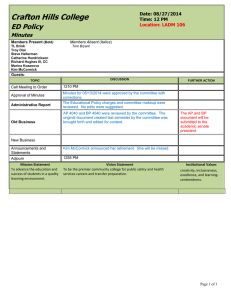

Project ASD (Aerial Surveillance Drone) TEAM SYNTECH KEN, ANDY, DAN, TRAVIS, RYAN 1/25/2011 Overview Team Syntech’s objective is to construct an autonomous quad copter that performs aerial maneuvers and reconnaissance functions. Team Syntech Redington, Ryan Le, Cartwright, McCormick, Hua 1/25/2011 Objectives (Low) Micro Controller commanding motors Autonomous stable hovering Safety measures (Basic Wireless Features) Emergency remote kill switch (copter goes dead) Remote hover button: copter returns to stable hover state Turning Planar movement LED’s Team Syntech Redington, Ryan Le, Cartwright, McCormick, Hua http://www.isys.unistuttgart.de/forschung/mechatronik/robo/quadk opter/index.en.html 1/25/2011 Objectives (Med) Collision durability Altitude adjustment Navigation using a system of beacons Can carry payload (specifically a digital camera) Recording pictures and/or video Wireless communication to a base station Team Syntech Redington, Ryan Le, Cartwright, McCormick, Hua 1/25/2011 Objectives (High) High altitude capabilities Spotlight LED Communication of video/picture to base station Pan/Tilt of the camera Obstacle avoidance Inductive charging at a base station Team Syntech Redington, Ryan Le, Cartwright, McCormick, Hua 1/25/2011 Software Environment Motor Control Control Algorithms Body Controller Remote kill switch Frame Microcontroller Beacons Motors Altimeter Sensor I/O Power Mat Main Battery Inclinometer Kill switch Data Receiver Camera Z-Accelerometer Wireless I/O Remote Control LEDs Power Monitor Programmer Main Power Aux Power LED Control Aux Battery Data Manager Wireless Motor Driver Navigation Serial Boot loader LEDs Team Syntech Redington, Le, Cartwright, McCormick, Ken Hua 1/25/2011 Software Microcontroller Camera LEDs Aux Pwr Motor Drive Main Pwr Serial Aux Batt Motors Main Batt Power Mat Props Team Syntech Sensors Beacons Redington, Le, Cartwright, McCormick, Ken Hua Wireless Bootloader LEDs Programmer Remote Data Receiver 1/25/2011 Implementation Micro controller -Atmel B series -AT32UC3B0256. -256KB FLASH 64-TQFP. 64 Pin Atmel Microcontroller Sensor -VTI Inclinometer DUAL 1G DIL12 SMD -SCA100T-D02 -X/Y tilt control data. VTI Inclinometer Team Syntech Daniel Redington, Le, Cartwright, McCormick, Hua 1/25/2011 Implementation Dual Power Systems •Main Power •Lithium Polymer •Triple Cell •11.1V •2250mAh •Supply for Motors •Auxiliary Power •Small- Single Cell Battery •Supply for electronics and Microcontroller Team Syntech DanielRedington, Le, Cartwright, McCormick, Hua 1/25/2011 Implementation Flight Characteristics •5” Propeller •Motor •0V-11V •4000 (RPM/V) •Max RPM (no load): 42k RPM •Weight: 40-70g Theoretical Load •Total Weight 497g + x •4x Motors = 160-280g •Li Poly = 180g •2x Carbon Fiber Plate = 13g •4x 5” Carbon Fiber Tube = 24g •Other Materials = x (g) •Static Thrust per motor •15k RPM = 180g lift •20k RPM = 330g lift •25k RPM = 510g lift •30k RPM = 740g lift •Estimated copter lift •4x Motors @ 16k RPM •800g Lift Team Syntech Redington, Le, Travis Cartwright, McCormick, Hua 1/25/2011 Risks and Contingencies Broken Parts during testing Ordering multiples of parts that are likely to be broken Insufficient thrust to lift payload Bigger propeller Adjust battery size Overall Project Structural Failure member(s) Purchase a commercial quad copter body kit Over budget Remove the camera from plan Materials for construction Team Syntech Not enough time Reduce features/capabilities from low category Going out of control Netting and a tether Kill switch and hover switch Unavailability of team Shift work to other members Reduce features/capabilities Controller does not work Buy off the shelf components (Arduino) Redington, Le, Travis Cartwright, McCormick, Hua 1/25/2011 Division of Labor and Responsibilities Travis Cartwright Embedded Design Software Developer Ken Hua Software Dev Lead Frame Construction Sub versioning Admin Documentation Andy McCormick Team Lead/Administrator Power Systems Budgeting/Scheduling Documentation Lead Daniel Redington Embedded Design Lead Software Developer Ryan Le Software Dev Lead Documentaion Frame Construction Team Syntech Redington, Le, Cartwright, Andy McCormick, Hua 1/25/2011 Budget Part Description Micro Controller And components Cost ($) The B Series AVR 256KB FLASH 64-TQFP 50.00 VTI Inclinometer DUAL 1G DIL12 SMD 150.00 Advanced Integrated Circuitry (2 revisions) 100.00 Motors and Drivers 4 Brushless EDF Outrunner with 4000 RPM/V 150.00 Camera and Mount Mountable camera for surveillance video recording/transmission 100.00 2 Thunder Power 2250 mAh LiPoly 115.00 0.015 in. Twill-Weave Carbon Fiber Sheet 11 in. x 8 in. 60.00 GWS EP Propeller 127x76mm, screws, epoxy, spacers, motor casing, mounting hardware 50.00 Printing PDR, CDR, Final draft of Users manual 130.00 Total All parts and Components needed $905.00 Sensors PCB Batteries Carbon Parts Props & Hardware Team Syntech Redington, Le, Cartwright, Andy McCormick, Hua 1/25/2011 Schedule By Preliminary Design Review – • Get the initial version of the users manual written • Set up SVN for code repository • Begin core circuit design • Fill out the UROP funding form • Order test parts • Order batteries Team Syntech By Critical Design Review – • Finish Core and Peripheral circuit design • Draft and finalize the board layout • First revision of prototype controller • First round of software implementation • Finalize body design Redington, Le, Cartwright, Andy McCormick, Hua 1/25/2011 Schedule Milestone 1 – • Motor and power systems functional • Chassis built • Hover functionality designed and functional Team Syntech Milestone 2 – • Functional turning • Ascend/descend code compiled • Establish wireless communication Redington, Le, Cartwright, Andy McCormick, Hua 1/25/2011 Functional Gantt Chart Team Syntech Redington, Le, Cartwright, Andy McCormick, Hua 1/25/2011 Questions? Team Syntech Redington, Le, Cartwright, McCormick, Hua 1/25/2011