Team 3D Erik Lorhammer Christopher Bermel Josh Cornelius

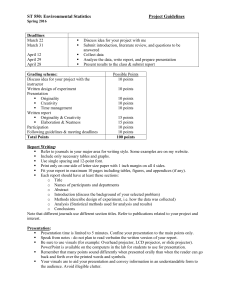

advertisement

Team 3D Erik Lorhammer Christopher Bermel Josh Cornelius Electrical Computer Engineering Electrical Engineer Electrical Engineer Objectives 3D Volumetric Display System will load pictures from an external memory source to main memory and send pictures to projector in a specified order. Project an image onto a rotating screen, the rotation of this screen will produce the appearance of a 3D image. The projected images will be 2D. Uses: Projection of 3D images can be used for multiple purposes, examples could include military use, topographical maps, educational use (DNA strands), medical, etc. Memory Card Power Supply (9V) Altera FPGA Power 120V 60Hz USB/VGA Optical System (Mirrors) Projector Control Panel Voltage Control Gears/Belt Motor Mechanical System Screen Motor Control Board (FPGA) Projector Main board of the system Connects by VGA to projector and has external memory interface. Connects to an external button panel which will provide all the inputs needed. (Load from external memory to memory, turn on/off system, start output to projector, stop output to projector) Development work will be done on the Altera Development Board present in capstone lab which already has Flash input and VGA output. Once development work is completed the Development Board will no longer be used and a PCB will be constructed with only the following components: Altera FPGA External Memory Input VGA Output Control Panel hookup Power Subsystem On-Board Flash Memory A series of images will be displayed on a rotating translucent screen. Each image will be taken from a different angle, so the projection of the sequence will appear 3 dimensional. Mirrors will rotate along with the screen so the projector can remain stationary. The translucent screen will transmit 50% of the light, so the image will appear to be floating in space. The projector we are currently looking at is a small handheld projector. The desired resolution is either 480x320 or 640x480, depending on the projector. The projector will connect to the control board through either VGA. http://en.wikipedia.org/wiki/Translucence Step-up Motor by Automation Direct which will operate at a certain RPM determined by our hardware’s FPS and the refresh rate of the projector we choose. Rotate disk that will contain a screen and set of mirrors by either a system of gears or belt Possible Materials Aluminum ▪ Rotating Disk (possibly Plexi-glass) ▪ Structurally hold Screen ▪ Base Purchase Gears Schedule FPS may not be sufficient to produce a quality 3D image. Lower resolution Decrease complexity Decrease number of colors (ie. 24 bit to 256 color) Unfamiliar Technology Altera FPGA (Cyclone II) ▪ Xilinx board (used in digital logic, but prefer not to) Interfaces ▪ Flash ▪ VGA Mechanical aspects ▪ Materials (metals, gears, belts, etc) ▪ Could use outside assistance to get mechanical aspects working correctly ▪ Torque of motor may be insufficient Financial Cheaper components that are still effective ▪ Instead of metal use alternate for example Plexi-glass or Plastics Request bailout for 3D volumetric display industry Schedule Uncertainty Other classes Work Weather Machining Schedule and Class Can’t exactly predict how long components will take us to build/test Cost Motor - $20 (AutomationDirect – STP-MTR-17048) Altera FPGA – SparkFun - $Free PCB – $10 Mirrors - $100 Projector - $400 Screen - $50+ Dome - $100 Base - $50 MFG / Production / Materials Cost - $400 ▪ Total: ~$1130 Potential Marketability Military, Education, Medical, Architecture, anyone who would ever want to see a 3D image, etc. Could be adopted for multiple other uses in the future. Purchase price – Mass Production - $5000 Environmental Impact of Manufacturing The union of the impacts of manufacturing the individual components plus putting them together. Energy cost of running the unit. Sustainability Parts from more than one vendor? No, the parts are chosen carefully to fit specific needs. Maintenance and support? Mechanical aspects of the system could possibly break. Need replacement parts for every part of the system, plan to replace every part. Will have User Manual and 1-800 number if system ever reaches market. Manufacturability Effect of Component tolerances? System could overheat, metal and mirrors and glass will be spinning at high speed. Worst-case analysis, expected production yield? Worst case is system becomes unstable during rotation or mirrors shatter during vibration as well as electrical components coming detached. 99/100 systems will be manufactured well as long as defects are not in our suppliers products. Testability? Straight forward, make sure all components work especially the mechanical components and put out dummy image to see if the full system is working. Compliance to regulations? Will have to keep system within FCC regulations, system will be shielded by its casing. Have to make sure the mechanical aspects are safe. Safety Safety in the workspace? Glass will be thick enough in final product to protect user from any demolition inside the globe. System safety issues? Discussed in earlier sections, the system will plug straight into the wall with shielded cables. Impact on society This product will have a huge positive impact on society. The pros will outweigh the cons.