Resistance-Start Split-Phase Motor sin T

advertisement

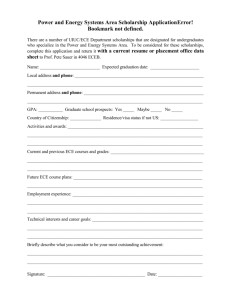

Resistance-Start Split-Phase Motor R = Rext Tlr ksp I mw I aw sin Tlr I aw sin ECE 441 1 Graphical Analysis Iaux decreases with increasing Rext angle α increases with increasing Rext Locked-rotor Torque “peaks” for an “optimal” value of Rext . Phase displacement angle α is between 25° and 30°. ECE 441 2 Practical Resistance-Start Motor “Centrifugal” switch or TRIAC Closed (shorted) when the motor is at rest Opens when motor speed is 75% – 85% of synchronous speed ECE 441 3 Practical Resistance-Start Motor Phasor Diagram at start-up ECE 441 4 Torque-Speed Characteristic ECE 441 5 Cutaway view of a Split-Phase Motor ECE 441 6 Capacitor-Start Split-Phase Motor Develop a larger value of Iaw sinα, and, hence, a larger locked-rotor torque Phase-displacement angle between 75° and 85° ECE 441 7 Capacitor-Start Motor Phasor Diagram at start-up ECE 441 8 Torque-Speed Characteristic Higher Starting Torque Same Running Torque as before ECE 441 9 Permanent-Split Capacitor Motor • Uses a permanently-connected auxiliary circuit containing a capacitor. • Smoother and quieter operation than resistor or capacitor starting motor • Speed control by autotransformer across the line, or external resistor or reactor (inductor) in series with the main or auxiliary winding (or both). ECE 441 10 Permanent-Split Capacitor Motor “Permanent” Capacitor Speed control by autotransformer ECE 441 11 Two-Value Capacitor Motor main Small capacitor for running auxiliary Large capacitor for starting Centrifugal switch ECE 441 12 Example 6-2 • Using the motor from Example 6-1, determine the capacitance required in series with the auxiliary winding in order to obtain a 90° phase displacement between the current in the main winding and the current in the auxiliary winding at lockedrotor and the locked-rotor torque in terms of the machine constant. ECE 441 13 Example 6-2 continued • From Example 6-1 Z mw 2.00 j 3.50 4.0311 60.2551 Z aw 9.15 j8.40 12.4211 42.5530 120 0 I mw 29.7688 60.2551 A 4.0311 60.2551 120 0 I aw 9.6610 42.5530 A 12.4211 42.5530 ECE 441 14 Phasor Diagram i',aw 90 60.26 29.74 ECE 441 15 Modified Circuit Z ' aw Z ' aw ' z , aw VT 0 ' I aw 29.74 z' ,aw 29.74 ECE 441 16 Impedance Diagram for Auxiliary Winding tan( ' z , aw X aw X C ' ) X C X aw Raw tan( z ,aw ) Raw ECE 441 17 Calculation of Capacitance X C 8.40 9.15 tan( 29.74) 13.628 1 1 C 194.6 F 2 fX C 2 (60)(13.628) ECE 441 18 Locked-rotor Torque Tlr k sp I mw I aw sin 120 0 I 11.387 29.74 9.15 j8.40 j13.628 Tlr k sp (29.7688)(11.387) sin 90 338.9 k sp ' aw 338.9 107.1 %increase (100%) 216% 107.1 ECE 441 19 Graphical Analysis Auxiliary winding current increases then decreases with increasing capacitive reactance (why?) Angle α increases with increasing capacitive reactance ECE 441 Locked-rotor torque “peaks” for the optimal value of capacitive reactance. The resulting phase displacement angle is approximately 75° 20