UNIVERSITY OF MASSACHUSETTS DARTMOUTH

advertisement

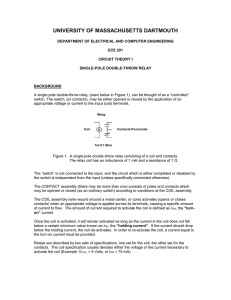

UNIVERSITY OF MASSACHUSETTS DARTMOUTH DEPARTMENT OF ELECTRICAL AND COMPUTER ENGINEERING ECE 201 CIRCUIT THEORY I SINGLE-POLE DOUBLE-THROW RELAY BACKGROUND A single-pole double-throw relay, (seen below in Figure 1), can be thought of as a “controlled” switch. The switch, (or contacts), may be either opened or closed by the application of an appropriate voltage or current to the input (coil) terminals. Relay Coil K Contacts/Term inals 1m H 1 Ohm Figure 1. A single-pole double-throw relay consisting of a coil and contacts. The relay coil has an inductance of 1 mH and a resistance of 1 Ω. The “switch” is not connected to the input, and the circuit which is either completed or disabled by the switch is independent from the input (unless specifically connected otherwise). The CONTACT assembly (there may be more than one) consists of poles and contacts which may be opened or closed (as an ordinary switch) according to conditions at the COIL assembly. The COIL assembly (wire wound around a metal center, or core) activates (opens or closes contacts) when an appropriate voltage is applied across its terminals, causing a specific amount of current to flow. The amount of current required to activate the coil is defined as ION, the “turnon” current. Once the coil is activated, it will remain activated as long as the current in the coil does not fall below a certain minimum value known as IHD, the “holding current”. If the current should drop below the holding current, the coil de-activates. In order to re-activate the coil, a current equal to the turn-on current must be provided. Relays are described by two sets of specifications, one set for the coil, the other set for the contacts. The coil specification usually denotes either the voltage or the current necessary to activate the coil (Example: VCOIL = 5 Volts, or ION = 75 mA). The contact specification will include the number of poles and throws of the switch contacts as well as the maximum voltage and current which the contacts can withstand (Example: single-poledouble-throw (SPDT) 125 Volt, 2Ampere contacts). Some other terminology about relay contacts might include “NORMALLY OPEN” (NO), “NORMALLY CLOSED” (NC), and “COMMON” (COM) as shown in Figure 2. K1 NO COM K NC 1m H 1 Ohm Figure 2. The contacts are designated as NORMALLY CLOSED (NC), NORMALLY OPEN (NO), and COMMON. If the switch contact is in the lower position when the relay is not energized, we say that the contact is “closed” and a connection is made between that contact and the COMMON terminal. (This position is defined as NORMALLY CLOSED.) Meanwhile, the connection between the COMMON terminal and the upper contact is “open”, and that contact is said to be NORMALLY OPEN. When the relay is energized, the switch will change position, connecting the upper contact with the COMMON and opening the connection between the lower contact and COMMON. K1 NO COM K NC 1m H 1 Ohm Figure 3. The relay under “energized” conditions. 2 SIMPLE RELAY APPLICATIONS Emergency Lighting System The circuit shown below in Figure 4 can be used to simulate an Emergency Lighting System, that is, a scheme to illuminate some lights from a Backup Power source when either the Primary Power source or a strategic Lamp fails. K1 R1 100 Ohm NO COM R2 K NC 100 Ohm 1m H 1 Ohm Prim aryPow er 12 V BackupPow er 9V Main 9V Em ergency 5V Figure 4. An Emergency Lighting System. The Main lamp is connected to the Primary Power through the relay coil. The Emergency lamp will be connected to the Backup Power if either the Primary Power or the Main lamp fails. The circuit is shown in the normal mode of operation, with the Main lamp connected to the Primary Power. In this scheme, the relay coil and Main lamp are connected in series to the Primary Power, a 12 Volt battery. As long as the Primary Power remains on and the lamp is good, the relay contact will be in the normally open (NO) position and the Emergency lamp will not be connected to the Backup Power. If the relay coil becomes de-energized due to either the loss of the PRIMARY POWER or the failure of the Main lamp (an open circuit), the relay contact will change to the normally closed (NC) position, connecting the Emergency lamp to the Backup Power, restoring lighting. In a “real-life” situation, the relay coil and Main lamp would be connected to 120 Volts AC while the Emergency lamp would be powered by a 12 Volt battery. In addition, there would be provisions to keep the 12 Volt battery fully charged while the Primary Power is on. 3 Backup Power System The circuit shown in Figure 5 shows a method of providing Backup Power to a load (the lamp in this case) when the Primary Power source fails. K1 NO COM K NC J1 Key = Space 1m H 750 Ohm Lam p Prim aryPow er 12 V 12 V BackupPow er 9V Figure 5. A relay circuit which provides Backup Power to a load (the lamp). The load is normally energized by the 12 Volt Primary Power source. The Primary Power, a 12 Volt battery, is connected across the relay coil. As long as the relay is energized, the lamp will be connected to the Primary Power via the NO relay contact. When the Primary Power is removed, or fails, the lamp will be connected to the 9 Volt Backup Battery via the NC relay contact. 4 PRE-LAB DESIGN PROBLEM Design, build, and test a simple alarm system that could be used to monitor the water temperature, oil pressure, and available fuel level for an engine. When a fault occurs, the system should TRIP by energizing a relay, causing an audible 1.9 kHz buzzer to sound and a Red LED to illuminate. The basic “sensors” are SPST switches. These individual switches will be “normally open” (NO), and will “close” when any of the following fault conditions occur: the temperature is too high the oil pressure is too low the fuel level falls below a certain minimum level. In addition, the system should provide a Green LED to show NORMAL status indication (switches are open), a Yellow LED to indicate which parameter has developed a fault condition, a method to SILENCE and RESET the system following a TRIP condition, and a scheme to TEST the system (by means of a separate push-button switch). The system will be powered by the engine’s 12 Volt starting battery (in our case, a 12 Volt DC Power Supply). Simulate your circuit using Multisim, and include a copy of the working simulation in your Pre-Lab. PROCEDURE / RESULTS 1. Construct the circuit of Figure 4, but substitute a Red LED for each lamp. The relay coil should energize and the “Main” LED should glow. Test your configuration by shutting down the 12 Volt Primary Power. Does the “Emergency” LED glow? Restore the 12 Volt Primary Power. The circuit should now be operating normally. Remove the Main LED to simulate an open-circuit failure (it’s OK to remove the LED with the power applied). What happens? 2. Construct the circuit of Figure 5 using the 12 Volt lamp. The relay coil should energize and the lamp should glow. Test the circuit by shutting down the Primary Power. What happens? Is the lamp at illuminated at the same intensity? Why or why not? 3. Construct the circuit which you designed in the Pre-Lab. Test the circuit’s performance, and modify your design if necessary. In your lab notebook, provide a complete circuit diagram, parts list, and technical description of your final circuit. 4. Provide a Multisim simulation of the final configuration of the circuit which you designed in the Preliminary Work and tested in the laboratory. 5