EQUIPMENT CONDITION ASSESSMENT AND ITS IMPORTANCE IN

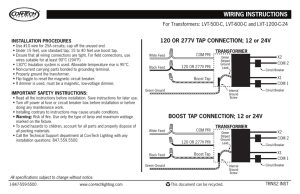

advertisement