Wichita State University Libraries SOAR: Shocker Open Access Repository

advertisement

Wichita State University Libraries

SOAR: Shocker Open Access Repository

Wind Energy Reports, no.10

Center for Energy Studies

Feasibility Study of Aileron and Spoiler Control Systems for Large

Horizontal Axis Wind Turbines

W.H. Wentz Jr., Melvin H. Snyder and J.T. Calhoun

Wichita State University

Recommended citation

W.H. Wentz Jr., Melvin H. Snyder, J.T. Calhoun. Feasibility Study of Aileron and Spoiler Control Systems

for Large Horizontal Axis Wind Turbines. Wichita, Kan: Wichita State University, 1979. -- 84 p.

Digitized by University Libraries and posted in Shocker Open Access Repository

Citable Link: http://soar.wichita.edu/dspace/handle/10057/6041

Terms of use: in the Public Domain

WER-10

l~;

nd Energy Report No. 10

FEASIBILITY STUDY OF AILERON AND SPOILER CONTROL

SYSTEMS FOR LARGE HORIZONTAL AXIS WIND TURBINES

by

W. H. Wentz. Jr .• and ro1.H. Snyder

Wichita State University

and

J.T. Calhoun

Consultant

Report of research conducted under NASA

Lewis Research Center grant NSG-3277

NASA Technical Monitor:

T. Richards

Wind Energy Laboratory

Wichita State University

Wichita, Kansas 67208

November. 1979

SUMMARY

Studies have been conducted to determine the feasibility of using aileron

or spoi ler controls as alternates to pitch control for large horizontal axis

wind turbines.

The NASA MDO-O machine was used as the basis for this study.

Results of the study show that either ailerons or spoilers can provide the

control necessary to limit turbine power in high wind conditions.

An aileron

system ;s recommended for the present app l ication, based upon the ability of

ailerons to provide self- starting and added power at low wind speed conditions.

The preliminary design study includes aileron component sizing and maximum

hinge moments . . It is recommended that ailerons be fabricated for testing on

the MOO-O turbine .

It is also recommended that theoretical modeling methods

for wind turbine performance be refined, and that wind tunnel tests be comducted to provide better data for airfoil characteristics at extreme angles

of attack with aileron- type controls.

CONTENTS

page

SUMMARY______________________________ ___ _________________ ______ ______ __

INTRODUCTION_ __________ ______ _________________ _____ ________ ____________

SYMBOLS___ ___________ __ ______________________ _________ _________________

COMPUTER MODELING___ _____________________________________________ ____ __

1

2

3

Bas i c Progr am , IIPROP" ______________________________ ___ ._. __________

3

Airfoil Characteristics Subroutine , "NACA XXII ______________________

6

7

Incrementa 1 Subrout; ne . "INCREM"__ ______________ ____________ __ ___ __

i

Post- Stall Behavior of Airfoil with Control Surface_________ ____ ___

Expanded Output Modifications__________________________ ___ _________

Convergence Problems and Re l ated Modifications_____________________

9

10

Hinge Noment_________ __ _____________________________ _____ __________

CONTROL SYSTEM OPTIONS STUDIES_ ________________ _____ _____ ______________

11

12

Control Surface Design Considerations___ _____ ______________________

12

8

Ailerons___________________________________________________________ 12

Spoiler Type_____ ________________________ ___ _______________________ 13

Spoiler Hingeline Location______________________________ ______ _____ 13

PRELIMINARY PERFORMANCE CONS IOERATIONS_________________________________ 14

leading- Edge Suction Studies ________ __ _____________________________ 14

Single Point Performance Ana lysi s __________________________________ 16

Overspeed Control_ __ ___ _____________________ ___ ______ ____ ___ _______ 18

COMPUTER STUDIES OF AILERON AND SPOILER CONTROL________________________ 20

Power Modulation at High Wind Speeds__ _______________________ ______ 20

Overspeed Contro'_ _________________________________________________ 21

Aerodynamic Starting_______________________________________________ 22

Power Increase at low Wind Speeds_ _________________________________ 23

CONTROL SYSTEM HARDWARE ____________________________________________ ____ 24

CONCLUSIONS__ _______ ______________________________ __ __________ ___ ______ 25

RECOMMENDATIONS ______ ____ _______________________ __ _________ ____________ 25

REFERENCES __ ________ ________ _____________________________________ ____ __ 26

FIGURES___ ______ _____________________ ____ ______ ________________________ 27

APPENDICES

;;

INTRODUCTION

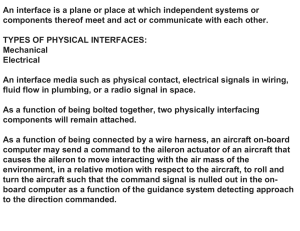

Current large scale horizontal-axis wind turbines utilize variable pitch

of all or a portion of blade span for starting. stopping. and modulation of speed.

However. design of variable- pitch turbine blades of large size poses several

structural and mechanical problems .

Fixed-pitch rotors for large wind turbines

offer advantages over variable pitch rotors or tip-controlled rotors.

The

blades of the fixed-pitch rotor are oriented so that the fatigue- producing

cyclic gravity loads are in the direction of the greatest dimension (the section

chordwise direction).

This mini mi zing of cyclic stresses results in weight and

cost savings . A fixed-pitch rotor does not require blade pitch bearings or the

complex bearing assemblies and linkages needed for pitch control and fUI"ther

stress reduction results from combining a teetering hub with fixed pitch rotor.

These factors contribute to significant cost savings of fixed-pitch rotors over

variable- pitch rotors.

The fixed - pitch rotor , however, has two inherent problems:

(1) start- up

initiation and shutdown control, and (2) prevention of overspeed . Setting fixedpitch blades at an ang le to maximize annual energy may result in near-zero

starting torques when the rotor axis is aligned with the wind, s ince the blades

are completely stalled.

It has been demonstrated that yaw control may be used

for start up of fixed - pitch wind turbines.

enough to prevent overspeed.

However, yaw control is not fast

Yaw systems operate slowly; as much as one minute

may be required to yaw sufficient ly to prevent overspeed . Typical overs peed

rates are so high that the rotor speed can double in half that time.

Although yaw control might be used to provide starting and to shut down at

low wind speeds, other means are required for overspeed control.

One possible

concept is the use of retractable spoilers on the outboard portion of the

blades to reduce rotor speed by decreasing section lift and by increasing drag .

An alternative concept is the use of hinged trailing-edge surfaces (ailerons)

which can act similarly to spoilers in preventing overspeed. and can also act

to improve rotor torque at less - than- design wind speeds. thus improving annual

energy output.

Spoiler and aileron control systems have been studied under a 6-month

grant from NASA Lewis Research Center . This report presents results of these

studies which include aerodynamic performance of aileron and spoiler controls

and their effects on turbine performance, selection of a control system si zed

for the NASA MOO- O 38.1 m diameter wind turbine, and preliminary design of

mechanical systems for control surface actuation and fail - safe operation.

SYMBOLS

a

ax ial induced velocity factor

a'

rotational induced vel ocity factor

B

number of blades

c

airfoil or blade local section chord

ca

aileron chord

Cs

spoiler chord

Cs

ai rfoil cho rdwise f orce coefficient .

ci

airfoil lift coefficient

Ch

hinge moment coefficient

cn

normal force coefficient

Cx

coefficient of force component in plane of rotation

2

cy

R

coefficient of force component in axial direction

r

local blade radius

cp

rotor power coefficient, power/~V3nR2

V

wind velocity

x

spanwise distance from center of rotor

X

tip speed ratio, wR/Vwind

a

angle of attack

o

deflection angle

,

relative wind angle

a

blade pitch angle

w

rotor angular velocity

maximum blade radius

COMPUTER MODELING

Basic Program, "PROP"

The computer program used in the studies conducted under this NASA grant

is PROP.

This program was originally written by Stel Walker and Robert Wilson

at Oregon State University for NASA (Ref. 1).

Prior to being supplied to Wichita

State University. some modifications were made to the program at lewis Research

Center to facilitate its use on the NASA computing system.

After the program was received at WSU. it was modified to permit operation

on the university IBN system 370 computer.

The program consists of a main

program and six subroutines:

Main Program:

3

PROP

Subroutines:

SEARCH

CAlCZ

TlPlOS

NACAXX

INCREM

BESSEL

The main program receives input information about rotor geometry, control

mode (tip section pitch, spoilers, or ailerons), and operation (varying rpm or

wind speed) through a series of data cards.

For the analysis reported here,

the following input items were considered constant and were not varied :

B= 2

BO

=

(number of blades)

.97

(NASA tip loss model)

XETA

=

HB

2 ft

=

0.167

(velocity power law exponent)

(hub radius)

R = 62.5 ft

(turbine radi us)

THETP

=

(pitch angle)

THETl

= 0

0 de9

deg

(twist angle at all inboard stations)

H = 100 ft

(hub altitude)

=0

(coning angle)

SI

deg

Blade planform geometry used in all calculations corresponds to the wooden

inboard blade (shown in figure 1) .

30%of radius.

The length of the spoilers and ailerons is

This geometry was entered by means of data cards.

Input data which were varied during this study included:

v

freestream wind velocity

OMEGA

angular velocity of turbine rotor

MCON

method of control (tip section pitch, spoilers,

or ailerons)

TlPICH

angle of pitch of tip section

4

AILDEF

angle of deflection of ailerons

SPDEFL

angle of deflection of spoilers

The program permits use of va ri ous sizes of radial increments in the calculation of performance.

Early in the analysis studies. comparison was made

of results of computation using radial steps ranging from 10% to 2%.

To minimize

error, 2% increments were used in all subsequent calculations.

In operation, the computer program starts at the outboard end of the

blades and calculates components of forces for each incremental radial blade

element, working inboard to the hUb .

local chords and amount of twist are determined by the subroutine SEARCH

using linear interpolation.

Subroutine CALC ;s then called to calculate the

axial and rotational interference factors (a and a'), the local angle of attack

and lift and drag coefficients .

section is shown in figure 2.

The relative wind relationship to the blade

The relationships between angle of attack and

lift and drag coefficients are obtained from subroutine NACAXX and modified

by subroutines TIPLOS (tip and hub losses) and INCREM (increments of c, and

cd due to aileron or spoiler deployment).

As can be seen in figure 2, angle of attack is a function of a, and a is

a function of the section lift.

Thus, evaluation of a is an iterative process

which is discussed in detail in a later section of this report .

ference (a 1 ) was assumed zero for all the present studies.

Radial inter-

Elements of force

in the plane of rotation (producing torque) and normal to the rotor plane (producing thrust) are thus determined by iteration at both ends and at the center

of each 2% span blade section.

The forces are integrated across the section using

Simpson's rule and then simply summed to give total quantities for the blades .

5

Airfoil Characteristics Subroutine, "NACAXX"

Airfoil aerodynamic characteristics used in the PROP computer code are

made available to the computer in the form of subroutine NACAXX.

This technique

permits the program user to develop the aerodynamic information in a form most

suited to his own needs, or most compatible with available data . The task of

the subroutine is to determine lift and drag coefficients for a given angle

of attack, and to return these coefficients to the main program.

In subroutine

NACAXX used for the present performance studies of the NASA MOD-O wind turbine,

the aerodynamic characteristics of the NACA 23024 airfoil are stored as a set

of algebraic equations, with logic to branch to the equation appropriate for a

particular angle of attack range.

The angle of attack at a given station is

calculated from wind speed, angular speed, radius, and induced factor, a.

In order to analyze an airfoil with a control surface. it is necessary

to identify geometric characteristics of the control surface, such as control

surface chord and deflection, as well as airfoil angle of attack.

In addition.

it is desirable to store information concerning control surface hinge moments

so that control surface actuation loads may be calculated.

In the present

research, it was decided that control surface data should be treated as increments to be applied to the basic airfoil characteristics.

for adopting this procedure:

There were two reasons

first, no data were available for the NACA 23024

section with spoilers and ailerons; and second. a control surface incremental

subroutine would have application to a variety of airfoils with minimal change.

A description of the incremental routine for aileron and spoiler controls ;s

given in the section which follows.

6

Incremental Subroutine. "INCREW

This subroutine receives control surface type. control surface chord, and

deflection angle as input information.

Output information is incremental lift

coefficient. incremental drag coefficient. and control surface hinge moment

coefficient.

The incremental data are added to the basic airfoil coefficients.

so that net or total coefficients are returned to the main program for evaluating blade element performance.

The incremental data used in this subroutine were obtained from wind

tunnel experiments conducted on a 21 % thick airfoil at WSU, specifically the

lS(l )-0421 airfoil as documented in reference 2.

Figures 3 and 4 show

incremental data from the reference for lift and drag coefficients, and control surface hinge moment data as a function of control surface deflection and

angle of attack.

Equations used to model the control surface data are

given in Appendix A.

Both the experimental data and the forms selected

for representing the data reflect the fact that spoilers and ailerons

are quite similar with respect to aerodynamic characteristics which

they produce.

It should be remarked that while the incremental subroutine has been arranged

so that control surface chord is an input variable, the data were obtained from

experiments with 20% chord aileron and 10% chord spoiler.

The resulting equa-

tions would be applicable to control surfaces with chord lengths differing by

as much as 50% from the source data values, but could lead to serious errors for

larger chord differences.

Furthermore. the spoiler data were from experiments with a spoiler hingeline location of 70% chord.

While using the present data base to approximate

7

spoiler characteristics for hingelines from 60% to 90% chord would probably

not results in large errors, hingeline locations forward of 50% would be expected to produce large errors, since it is known that spoilers are much more

effective at forward locations.

In order to determine the overall hinge moment required to actuate a

control surface, it is necessary to integrate the local section hinge moments

across the span of the control.

This integration is accomplished in program

subroutine CALC, in parallel with integrations of other spanwise integrations

of blade torque and thrust loads.

Post-Stall Behavior of Airfoil with Control Surface

Post - stall characteristics of airfoils have been investigated for only

a few section shapes.

This lack of data is unfortunate, since fixed pitch

wind turbines operate over an ang l e of attack range from approximately 0° to

90°.

The aerodynamic characteristics of the NACA 23024 airfoil as modeled

in subroutine NACAXX for angles of attack beyond stall were based upon wind

tunnel tests of the symmetric 12% thick NACA 0012 section.

For post-stall

angles of attack with spoiler, it is assumed that the spoiler effectiveness

vanishes and that the basic section data apply.

This assumption is believed

to be reasonable since for high angles of attack, the airfoil will separate in

front of the spOiler, rendering it nearly ineffective.

For an airfoil with aileron deflected, on the other hand. the lower surface

shape is changed and the lift and drag will be different , even for 90° angle

of attack.

Since no experimental data for airfoils with ailerons at extreme

angles of attack are available, a model was developed for the present study

based upon theoretical results from potential flow analysis of flat plates using

8

free streamline techniques.

Appendix A shows theoretical results for

Kirchoff flow, modified by cor recti ng to a more realistic base pressure.

This modified theory is then used t o develop aileron loads for post -stall

cases.

Expa nded Output Modifications

In order to facilitate analysis of effects of spoi l er or ailero n deflections on wind turbine performance. the output of t he comp uter program was

expanded.

The computer program output was modified to provide two alternative types

of display of the performance resul ts . The "long pri nt-out" shows loca l values

of velocity. angle of pitch. angle of attack. coefficients of lift and drag. and

the resulting local contributions to torque. thrust. and a.

Integ rated results

are also printed including torque, thrust, power, cpo average a, and hinge moment.

The "short print-out" displays only the integrated values .

Examples of both

the "short print-out" and the "long print-out" are shown in fig ure 5.

The reason for the long print-out is that it permi ts an investigator to

examine local wind angles and angles of attack across the radius from hub to tip,

the resu l ting blade loading and induced effects.

An additional optional print-out was added to the program during the

present research.

At each radial station, the computer seeks to satisfy con -

tinuity and momentum relationships by an iterative procedur e involving a , the

induced velocity factor, net angle of attack on the blade section. and the

resulting section lift and drag coefficients.

In order to examine this iterative

process, an optional command causes the printer to list each suc cess i ve estimate

of local a , c t

'

cd' and the factor a.

If a does not converge i n the 50 itera -

tions a wa rn ing is printed on the output sheet.

9

Convergence Problems and Related

~lodif;cations

As outlined above , estimation of the axial interference factor, a, is

an iterative process involving the following steps:

1.

Assume initial values of a = 0 , a'

=

O.

r

(1)

a:. -

3.

Calculate

4.

Calculate Ct and cd as functions of a, including any increments

due to spoiler or aileron deflection.

5.

Calcu late cy = CtCOS$ + Cdsin$

and

e

Cx

(2)

= Ct sin $

cd cos $

(3 )

(4)

Be

6.

7.

Calculate

1rr Cy

a: --""'--'",,-8sin2$ +BC

Cy

,r

Be

;r

Cx

Calculate a': ---'"'---"----

(5)

(6 )

8 sin $ cos $

8.

Compare a or a ' to previous values to check for convergence.

If not converged, return to step 2 and repeat.

This process had been programmed in subroutine CALC to perform the iteration

up to 40 times with damping applied on the fourth, tenth, and fifteenth cycles .

It was found that at tip speed ratios, X, of more than 15, the average values

of a were predicted to be greater than 0. 5 for the straight blade at zero pitch

angle.

For bl ades with negative or positive loading outboard--as \'Jith tip

pitched, ailerons deflected, or spoilers deployed-- high values of a were obtained

10

at lower values of X, with local values of a = 1.0 (or greater) being obtained .

these unrealistic values were usually obtained at low wind speeds out-

t~hile

side the normal operating range of the rotors, it was felt that they cast doubt

on all performance predi ctions.

In order to i mprove calculation of a, the possible number of iterations

was increased to 50, damping was applied to each cycle, and local values of a

were limited to

-0.5~a!:0.5.

Also, an optional procedure was made available

which disregarded the induced velocity by setting a = O.

Figure 6 compares the

results of calculations with (1) a unlimited, (2) - O.S sasO.S, and (3) . . 0.

The remaining performance pred ictions were calculated with the restriction

that -O.S sasO . S.

Hi nge Moment

Hinge moments for the spoiler studies were obtained directly from the

wind tunnel data of reference 2.

For the aileron studies, however, hinge moment

data from this reference are not di r ectly applicable, because of the large djfference in airfoil camber between the two sections, especially near the trail ing edge.

The equation for hinge moment coefficient is given by:

(7)

where:

ch

= hinge moment coeffici ent

cho

= hinge moment coefficient at a = 0° and 6 = 0° (a function of camber)

= rate

of change of hinge moment with alpha, obtained from the

data of reference 2.

= rate

of change of hinge moment with aileron deflection,

from reference 2.

11

Since the value of Cho depends on camber of the section. and no experimental

data were available for the NACA 23024 section. a value for this parameter was

obtained by integration of the pressure distribution over the airfoil trailing

edge region using theoretical data from reference 3.

A listing of the computer program with all the modifications described

above is given in Appendix B.

CONTROL SYSTEM OPTIONS STUOIED

Control Surface Design Considerations

Geometric variables available to the designer for the present study are:

control surface type {aileron or spoiler}. spanwise extent of control surface.

control surface chord. and for the case of the spoiler. hingeline location.

Most of the torque produced by a propeller-type wind turbine is produced from

the outer portion of the blade.

For this reason, torque modulation devices

should be located on the this portion of the blade.

pitch control over the outer 35% of the blade.

The MOD-O turbine uses

Control surface span for aileron

and spoilers studies was selected as the outer 30%.

Ailerons

Ailerons have several characteristics which make them attractive as

candidates for wind turbine aerodynamic control.

First. they produce nearly

the same aerodynamic effects as spoilers of the same chord and deflection angle.

Second, ailerons have the capability of providing positive as well as negative

increments in lift.

Furthermore, downward deflection of ailerons will increase

maximum lift coefficient.

The ability to increase lift at low wind speed con-

ditions is attractive. since increased lift can be expected to result in increases in torque and hence power production.

12

Spoiler Type

Plate and plug type spoilers have both been successfully employed on

aircraft (see sketch below).

c

c

Plug-Type Spoiler

Plate-Type Spoiler

Sketch A - Spoiler Types

The two types are essentially equal in terms of lift and drag increments

produced for a given projection height.

The plug type have low actuation loads,

but reduce torsional stiffness and strength of the airfoil more than the pl «te

type.

The plate type also causes less penalty if mis -rigged, and they have

hinge moments which" tend to close them.

Based upon these considerations, plate

type spoilers were selected for the present application.

SpOiler Hingeline Location

Experiments have shown that spoiler effectiveness increases as the location of the spoilers is moved forward (ref. 4).

Unfortunately , forward spoiler

locations results in a time lag between actuation and change in lift.

Fpr this

reason, forward spoiler locations have rarely been selected for airplane con trol systems.

In the case of the wind turbine , the time response requirements

are not so severe.

In aircraft, control response must occur within the time

required to travel a few chord lengths.

13

low solidity wind t urbines such as

the MOO-O machine have blade tips I'lhich travel a large number of chord lengths

per revolution (more than 100 chord lengths at mid-control position). and control response within one revolution is considered quite satisfactory.

A second

consideration for spoiler location is the effect on the structure of cutting

into the airfoil, and a th ird consideration affecting the choice of spo iler

type and location is the effect of "mis-trilTllled" or "mis-rigged" spoilers on

drag at conditions for which spoiler deflection should be zero.

In addition,

any gap or protuberance associated with the spoiler or actuating mechanism

will add to the basic section drag, and the penalty associated with drag of

this type is much more severe for forward locations than for aft positions .

It is a cardinal rule of airfoil design that leading edges should be kept as

smooth and uncluttered as possible.

Based upon these considerations, the pre-

sent design studies were conducted for spoilers with hingeline locations aft

of 50% chord.

Because of the availability of data for spoilers with a 70%

hingeline, that location was selected .

PRELIMINARY PERFORMANCE CONSIDERATIONS

Leading-Edge Suction Studies

Traditionally, aerodynamic characteristics of airfoil sections are studied

in terms of lift and drag coefficient components of the resultant force.

Another

set of components which are sometimes used are normal and chordwise force coefficients.

For a wind turbine blade element with zero twist and zero pitch.

only the chordwise force produces torque .

It is. therefore, instructive to

study the airfoil characteristics in terms of this torque producing component,

called "leading edge suction."

The relationships between cl_ cd' and the chord-

wise and normal coefficients are:

14

cd*cOs (a)

(8 )

c n = cl * cos {a} + cd * sin(a )

(9)

Cs = cl*sin (a}

where:

Cs

cn

~

suction force coefficient. positive forwa rd

= normal force coefficient, positive upward

Figure 7 shows the cf., cd and Cs as functions of angle of attack for the

NACA 23024 airfoil with 20% aileron. A theoretical relationship between Cs and

angle can be derived for a symmetrical section from this airfoil theory, as

follows:

C1

= 2.sin(a)

,

(10)

Substituting these values relationships into equation (8) above, the following result is obtai ned:

( 11 )

In real flow, drag is present, and at zero angle of attack Cs is equal to -cd'

At angles of attack near stall. the suction decreases abruptly. and again

becomes negative .

Thus the useful angle of attack range for developing posi-

tive power is from the angle at which enough "theoretical" suction is developed

to overcome the basic section drag , up to the angle of attack at which stalling

occurs .

For the NACA 23024 airfoil the range of angles for positive suction is

between 2° and 17°.

A second region of positive suction appea rs at about 60°

and remains up to 90°.

15

The relationship between wind speed, rpm, and blade angle is s hown in

figure 2.

When the turbine axis is aligned with the wind, the angle of

attack on the blade will range from 90 0 at zero rpm to 00 at infinite rpm.

For an untwisted blade element at zero pitch angle, the angle of attack

will be equal to the

angle ~ .

For low lift coefficients and low blade

solidity, the induced velocity factors a and a' will be small .

It is

useful to assume the limiting use of zero induced effects to study trends.

Setting a = a':: 0,

tan(o) = tan(.) =

(12 )

Single Point Performance Analysis

Selecting the 75% radius station as a representative station for blade

element analysis, this gives:

Vwind

tan a = w(.75R}

Rearrange:

w =

Vwind

.75R (tan(o})

( 13)

(14 )

Using this relationship, and a specified wind speed , the rpm can be calculated

corresponding to a given angle of attack .

From the cs curve for the NASA

23024 airfoil, it ;s seen that zero torque (zero cs) will occur at several

angles.

For a wind speed of 54 m/s (120 mps), equilibrium rpm values are cal-

culated as shovm

ir.

Table 1:

16

Equilibrium States at Zero Torque

Table 1

ALPHA

VW1. nd

RPM

2°

54 m/s (120 mph)

1029

1]0

54 m/s (120 mph)

116

60°

54 m/s (120 mph)

21

Th i s study shows that the highest rpm corresponds to the lowest angle of

attack.

The question of which of the possible equilibrium states wi l l really

exist is answered by considerations of stability .

plot, and realizing that torque increases as

Examining the Cs versus

s increases, and that rpm decreases as a increases, the question of stability ;s easily understood.

C

Sketch B shows these characteristics:

I

Torque

V wind = Constant

t

Cs

+

0°

2°

60°

17°

90°

a -

-

Sketch B - Stability

17

rpm

Q

Since an increase in rpm from point 1 will result in negative torque,

and a decrease in rpm will result in positive torque, it is clear that this

point is in stable equilibrium.

characteristics.

Point 2, on the other hand, has the opposite

An increase in rpm from point 2 will result in an increase

in torque. accelerating the rotor toward point 1. and a decrease in rpm from

point 2 will result in negative torque, decelerating the rotor toward point 3

Thus. point 2 is unstable.

These same considerations will shows that point 3

is a second stable equilibrium point.

These arguments are easily generalized to state that equilibrium points

with positive slope on the graph illustrated will be stable, while equilibrium

points with negative slope will be unstable.

To protect the wind turbine

from overspeeding in high wind with loss of electrical load on the ge nerator.

it is necessary that either no stable equilibrium states exist, or that

the stab 1e equi1 i bri urn "runaway" rpm be low enough tha t no damage wi 11 be .

sustained. and the remaining rotor energy can be absorbed by the system mech anical brake.

The sketch shows that point 1 ;s the most dangerous equilibrium

point. since it corresponds to the highest stable equilibrium rpm.

Overs peed Control

In the event of electrical failure of a generator being powered by a

wind turbine, it is necessary to provide means for preventing overspeed or

"run- away" which would result in overstressing of the rotor structure and subsequent failure.

For large wind turbines this poses a difficult problem for

a mechanical brake design.

The preferred method ;s to use aerodynamic braking

such as pitch control or similar means.

The braking device must be capable

of functioning not only at the rated or design wind speed. but also at the

18

highest wind likely to be encountered.

For the present study a hurricane 'tli ;; d

speed of 54 mls (120 mph) was selected as the maximum wind s peed.

Combining

the requirements of a IIdouble emergency II s i tuation consisting of generator

failure along with hurricane wind results in a design requirement t o prevent

overs peed with zero torgue and wind velocity of 54 m/ s.

Figure 7 shows the relationship between c s and alpha for aileron

deflection of -60° , and spoiler deflection of 60°.

The results for

60 ~

upward deflection of either spoiler or aileron show that the region of

positi ve Cs in the low (pre-stall ) angle of attack range has been eli minated.

Thus no positive torque will be developed over this range of an gles. At

angles of attack beyond 60 0 however, positive Cs persists even with aileron

or spoiler control surface deflected upward

be developed.

60~,

and positive torque will

From the arguments given earlier, an equilibrium "run-away"

state can be expected at conditions corresponding to 60° angle of attack.

For the hurricane wind speed of 54 mis, the equilibrium rotational speed

will be about 21 rpm.

Since this rotational speed is well below the operat- ·

ing speed of 33 rpm, it does not pose a hazard in terms of centrifugal blade

loads.

Mechanical braking must be used to bring the rotor to rest.

From these preliminary studies based upon simplified analysis and hand

calculations, it is indicated that either a spoiler or an aileron system will

be adequate for providing overspeed protection to the turbine.

The next sec-

tion documents more sophisticated computer studies of turbine performance with

aileron and spoiler controls, which confirm these preliminary findings.

19

COMPUTER STUDIES OF AILERON AND SPOILER CONTROL

Power Modulation at High Wind Speeds

For wind speeds greater than the wind speed for which the electrical

generator is rated, it is necessary to either take the wind turbine off-line

or to Hdump" power by aerodynamic or other means .

With an aileron or spoiler

control system this "dumping" ;s accomplished by deflecting the control up-

ward to reduce lift and torque.

Figure 8 shows power coefficient vers us tip

speed ratio for the basic rotor, and the rotor with full up aileron, and with

full up spoi ler .

These results also show that either the aileron or spoiler

can provide the control necessary to reduce power to zero over the normal range

of tip speed ratios.

Because of the potential of the aileron to provide start-

ing torque and to provide increased power at low wind speeds, the aileron was

selected for further studies.

The data in figure 8 show that the aileron chord could be reduced considerably. perhaps as much as 50%, and still provide necessary overspeed protection.

While smaller aileron chord would reduce cost. it was decided to retain the

20% aileron chord size for two reasons.

First, if one aileron became inoperative

the rotor coul d be stopped with the remaining aileron.

Second, it is known from

experimental tests that the PROP code and similar theoretical methods underpredict maximum power by a considerable amount.

Therefore, a substantial ma rgin

must be provided in the design of a control system using these analytical

methods.

If experimental evaluation of the new control system reveals that

it is oversized. corrective action can be taken at that time .

Improved aero-

dynamic modeling for wind turbines should be developed to reduce discrepancies

20

between theory and experiment in order to reduce costs of experiments and

avoid expensive design errors.

Figure 9 shows how power modulation would be accomplished with the 20%

aileron control system for a synchronous generator operating at 33 rpm.

wind speeds lower than 8.2 mls (18 mph)

~Iith

For

zero control deflection. the power

developed is lower than the rated value of 120 kW shaft power. corresponding

to 100 kW of electrical power.

For wind speeds in excess of 8.2 mls (18 mph).

the turbine is capable of producing more power than the generator can absorb.

By deflecting the control surface upward. power can be modulated to provide

the required 120 kW at speeds up to 12.9 mls (29 mph).

For speeds greater

than this value, it will be possible to provide 120 kW by using down aileron

deflection, an option not possible with spoilers.

Thus the aileron system

can provide rated power up to 15.6 mls (35 mph).

Overs peed Control

Computer studies with full up aileron were conducted at the hurricane

wind speed (54 m/s) condition described earlier. for rotational speeds ranging

from 10 to 30 rpm.

occurs at 19 rpm.

These runs show that the zero torque "runaway condition"

This value compares very favorably with estimate of 21 rpm

from the simplified analysis given in Table 1, and confirms that the proposed

control system will provide adequate overspeed protection.

The control system must be capable of providing actuation forces sufficient

to overcome the cloSing aerodynamic hinge moment.

The critical design condi-

tion is maximum overspeed rotational speed of 40 rpm with 60° up aileron at

zero wind speed.

The hinge moment for this case is 186 N-m per aileron.

21

Aerodynamic Starting

14ind turbines with pitch control are ordinarily started by rotating

the blades to an unstalled angle, and then decreasing the pitch angle as rpm

increases.

l~ith

a fixed pitch rotor, very little starting torque is developed,

and other means for starting must be employed.

Recent tests by NASA with the MOO-O turbine have demonstrated that starting can be effected in a fixed pitch mode by yawi ng the rotor away from the

wind.

While this mode of operation is possible for a large scale machine,

it is inconvenient in that yaw rates must be low to prevent over-stressing the

rotor system.

With an aileron control system it is possible to generate starting

torque without yawing the rotor away from the wind . At zero rpm the effective

angle of attack is 90°, which means that the basic blade will be fully stalled.

and torque will be nearly zero.

torque is provided.

IHth up aileron, however, a larger starting

The computer code used for performance studies is not

capable of calculation at zero rpm, so runs were made at very low rpm values,

and the results were extrapolated to zero rpm.

This study shows that the

opti mum aileron angle for starting is _60° , and that a starting torque Qf

778 N-m (574 ft - lb) is available at a wind speed of 3.6 mls (8 mph) .

Because

of the dynamic pressure effect, this torque will be proportional to the square

of the wind speed.

Table 2 shows starting torque for several wind speeds.

Whether starting by use of ailerons can actually be effected depends

upon two factors which have not yet been determined.

of the generator and gear train must be overcome.

First, the friction

Second. once starting is

achieved. rpm must be increased to the point that the blades become unstalled

22

Table 2 - Starting Torque with 60° Up Aileron

Wi nd

Torgue

S~eed

2.2 m/s ( 5 mph)

304 N-m

3.6 m/s (8 mph)

778 N-m

4.5 m/s (10 mph)

1216 N- m

so that the operating speed of 33 rpm can be achieved.

Accelerating the rotor

to an unstal1ed state cannot be simulated with the present computer codes.

Ful'-

scale rotor tests will be required to evaluate the practicality of this starting

method.

Power Increase at Low Wind Speeds

Another interesting control option ;s possible with the aileron system.

At wind speeds lower than rated, positive aileron deflection can be utilized

to increase power available.

In order to assess the benefits of aileron deflection at speeds below

rated. it is necessary to calculate annual energy output for competitive control schemes using some mathematical model for the wind probabi lity distribution.

In the present study, a Rayleigh distribution has been used.

Table 3

shows results of a study of this type, comparing zero control with optimum

aileron deflections.

Optimum aileron deflections are 5° or lower.

Table 3 - Use Of Ailerons to Increase Annual Energy

Mean

5.36 m/s

(12 m~h)

Increase in

Annual Energy

1. 8%

23

nd Speed

5.81 m/s

l~i

( 13 mph)

6.26 m/s

(14 m~h)

1.6%

1.3%

These results show that using optimum aileron provides small gains in

annua l energy .

If the ra t ed power 'Here hi gher. or mean ','l i nd sp eeds lower .

larger i nc reases would result.

Appendi x C gives the deta il s of th i s study .

CONTROL SYSTEMS HARDWARE

The aileron system is shown in figure 10.

The control surface is' hinged

at the upper surface, providing maximum leverage for the actuatio n pushrod.

Travel limits are 60° upward and 15° downward, since maxi mum up travel is

needed t o limit rotor power i n high wind conditions.

The 15 0 down travel is

adequate for providi ng added power at low wind speed condit i ons.

A bell crank

tra nsfers spanwise motion of a pr imary push rod to chordwise motion.

The

primary push rod is actuated by a hydra ulic cylinder located in the inboard

portion of the rotor.

The counter-weight shown in the figure acts under the influence of

centrifugal force to drive the ail eron to the full up position, providing

fail -safe operation in the event Of hydr aulic system failure.

The hydraulic

cylinder works against the weight to bring the aileron to a desired setting.

The decision t o locate the hydraulic cylinder on the rotating blade was made

largely because of existing hydraulic hardware used for pitch control on t he

MOO-O machine.

In other appl i cations it would be quite feasib le to locate

the hydra ul ic cylinder within the rotor hub, and tra nsfer the needed spanwi se

actuator motion through a push rod extending to the rotor hub.

A mechanical

latch locks the ailerons in the full up position until released by restorati on

of hydraulic system pressure.

The aileron structure consists of aluminum hinge, ribs. and skin.

Tors ional

stiffness of the structu re is such that actuation loads can be i ntroduced at the

24

aileron root. eliminating the need fo r providing actuators at mid - span or other

locations.

Modifications to the forward portion of the blade are minimal, con-

sisting primaril y of cutting off the aft portion and installing a trailing spar

and the ai rcraft-type piano hinge to accommodate the aileron.

More detailed

design information is given in Appendi x D.

CONCLUS IONS

1.

Either ailerons or spoilers could be used to prevent runaway and to

modulate power at higher than rated wind speeds.

2.

An aileron system was selected as prime candidate fo r the present appli-

cation, based upon considerations of providing power output gains at low wind

speeds, and the possibility of starting without yawing the rotor away from the

wind.

3.

Preliminary loads analysiS including hinge moments have been developed

for a 20% chord. 30% span aileron control system for the MOO-O turbine.

4.

The system. as designed, provides overspeed protection at hurricane

wind speeds. low wind speed starting torque of 778 N-m at 3.6 m/ s. and 1.3 to

1.5% increase in annual energy compared to a fixed-pitch rotor.

RECOI+IENOATIONS

1.

Aileron hardware should be developed for testing the aileron control

concept on the MOO-O turbine.

2.

Theoretical models for wind turbine performance should be improved

to diminish the disparity between theoretical and experimental power values.

3.

',oIind tunnel tests should be conducted to provide a better data base

for airfoi l characteristics at high (up to 90°) angle of attack. with and

without control surface deployed.

25

REFERENCES

1.

Wilson, Robert E., and Lissamaman, Peter B.S.:

Applied Aerodynamics

of Wind Power Machines. NSF RANN. Grant no . GI-41840. May 1974.

2.

Wentz. W. H"

Jr .• and Fiscko. K.A.:

~Hnd

Tunnel Force and Pressure

Tests of a 21 %Thick General Aviation Airfoil with 20%Aileron,

25% Slotted Flap and 10% Slot-Lip Spoiler.

NASA CR 3081. 1979.

Theory of \<I;n9 Sections.

3.

Abbott, I.H., and Von Doenhoff. A.F..:

Dover Publications. 1958.

4.

Wenz;nger, C.J., and Rogalla, R.M.: Wind -Tunnel Investigation of

Spoiler Deflector. and Slot-Lip Lateral Control Devices on Wings

with Full-Span Split and Slotted Flaps.

26

NACA Rept . 706. 1940.

Note:

C/R

R=19.0Sm (62.Sft)

-'-

o

I

.192

.032

- . / Variable Pitch Control

~

~///~

1. 000

.647

x/R

Leading· Edge

. 700

I

N

"

20% Chord Aileron

10% Chord Spoiler

70% Chord Hingeline

Chord Lengths

x/R

.032

.192

.647

1.000

e}H

.0960

. 0960

.0640

.0333

Figure 1 - Blade Planform Geometry

v

--=.,.. - -- -- --- - -

•

__

•

__

0

__

•

__

•

__

(al Streamtube attenuation of axial velocity.

V(l-a)

W.r{l+a I

)

(b) Blade angles

Figure 2.

Blade Element Velocities

28

Symbol

-'.

-

. 0 351 C

• 005c Cap

:::iL.C

".

Alpha

..

_8°

"

~

0°

4°

Z

8°

I!l

_4°

- .~ .~

Note

Data from reference 2

CaT Incremental Lift

Fi g ure 3 - 20% Aileron Incremental Effects.

29

Symbol

-'.

e!

A

.'. .

X

.0050

(b) Incremental Drag

Figure 3 - Continued.

30

Alpha

-8·

-4·

O·

4'

I

:'. 'r.. '~ L_L2p,!_

\ \ '\:, . ~ 1

:

\: h..:i: :b. K.: . i

! ~': hi':"ll

•

';

-'-i ' oL

", ","""'

1',,

' i

I:

: ";

,Symbol

o

-S·

o·

o

S·

o

--"

,

oL

;

",; Gu;-::

;

'a

I 1-'

.1. ·1

·'1 T :'"

1 '++ _+++_~ , ~~~ :

:

I.

i

1

.;

I~ ~ I ~ ~ I

!

!,

'!

o

12·

~

16·

!

Ii

' ; '1

1·:

1

I

'I

"-'...~

+_+_ ,_

"'-

1 ~

l--' ~ ~

' ?-..,

d:~:++I+-ril-'+i+H-+-I~

i, I+t-I--;-

(c) Hinge l10ment

Figure 3 - Concluded.

31

~

....L

Note

Ah

Data from referen c e 2

I~-

---

- - - - -- -- - -

c

Synbol

Alpha

-So

OJ

.": ,-:;; In i: I:] il'!! !1111i1't ':

J

-,.

A

O·

"

'"

~

0

··,-·,·, :;1;,··

W

N

I

' j~' ~ ~ :",b#,f

0 ,::" ' .~j..

O~,~ ""p:

, ::: ~;

. : l~·J.~- ~· ~·'~<, ~tt+

':' ii_po' ~t~

a ~.fi*-.

0 0f"I

1' Qf-t~

~- .' . at-tt1

:!T 10

..-t '...' rm

'.'...·,,.±.b:~

, ~: "l..1·

.

, lo y " .,

r,o

it}

ct

,,·~

··· ~': :~~'~'I<;

~.

I..

~: J

, .........

m

,I,;

:,.

'I

,

'I, ,.'

I

- , ---,

6h/ e H".j ~.Lf"1"

- -r:-:

' .j,. c'

..i-LO..LC.!-.i·....1L;:Il,_L..L.

._ "_._...__,

,. L .

'1 :::r - r:-'l: .

, 111 I ' :

'H

" i' t" '1'' r 1j'''''m'' .'"

'

ht'''t1i118

'j;.':'. jtf::

!;.' ll~

-" '=

:::' '.; ..: "j. ~~ ;:: :: .;: I': ;". ',Ii;: h"~

'~:!:'

".1'''·'1..- ·t.ill.

":, ::;: ::;:, ..,,,.:,:., ~:Pl.

"'ftI;'' ::: i!·.i -- . . ." -' ,;;. :.. ""1"·1

.. ," .,... ,. "1'"

.. ,. ..-' ~

:';1." ,"..,J,.. ....

. I

:!u

~:! I! "' .,,'

., ,,,~'1..... ,. ." ".. ...... . .

':":' ill±i

"""'"

,:

.

• • . -.

,.1 •

I'

(a)

Lift

:.

L.

6h/e

I:++f:-I

I

'J- +-I..I.

. - I --Ti--T':,, : ·L:·1 - -C':

I

:t . I

(bl

Hinge Moment

Figure 4 - 10% Spo i l e r Increme nt a l Effects.

-.

H - -1-::-:- f ~'

" ,

&S

\

~

C_-__

~6S

~h \

,~'

c

Symb o l

w

w

(c) Drag

Figure 4 - Concluded.

Alpha

- S'

'•"

"..

-4'

0'

4'

Z

S'

c.. -= -• -= · -·

•

•

0

~

••

•

C

~

•

••

x.c_

•d

CO

=

-

· =,·

d

o

-.

----Z''': _

.

_

'"

N

o

• • • •

,,

,

0'

o

•

Zo

• •

•

_z

-~

•

,

Cd

-

o

d~

•

~.

·

o

c.

,

Z_

-=

,"

•

c

•o •oc

=

@

c

~

• •

o

N

c"

.,

•o

•

•

• •= =,

z 9

c

•

~j

-~

•••

~

c

~

•

~

•

,

=

N

••

o

o

o

o

N

N

N

N

Z

~

~

.10"' _U.

- 2:=

.JU

'J

~c

~

-•

_

=

~

,C

•

~.

C

•Cd_

c

••

Z

C

o

o

c

N

o,

o

N

N

~

N

N

N

,

o

•>

C

•

•• • •

o

• •~ •• o• • •• ••

•

•

=

•, •, , • •

•, • o, •,

N

N

N

N

N

N

N

N

N

N

=

o

o

=

•

•=

N

N

o

o

o

o

o

o

o

o

o

o

•

o

o

o

o

o

o

o

- · ·

----...

, ..

- - -· -· -·

--· -- -· -· - -.

-· · ·-· -.

·'.--.=

~_C

N

g

•• • •o

•o • •

= •

=

•, •, ••, •, , •, ~, , ••, •,

•o •

•

• •

N

N

~

C

o

N

•

- · -· - ··

...-

o

o

N

;:

~

,o

-=

g

N

N

••

·

~

0

C

N

c

~

o

• •• •• •o •o •o• •o •o •o

=, o o, o c, o, o,• o, o, =,

•=

,

=

•

--•

N

,

%

o

N

N

N

----.!.

•z

'0

· · ·

•o o

o, o ,;, , , , o, o,

• • • • •

•

o o o

•

•o • •

• • o •

•

• •• •

•

• •

•= •=

= o o

Z ,

=~

N

N

N

=

~

o

~

. --•· •••· •-· ••· -•· .••. -•• -•· •••· ••· ••·

o

=, =, =,

d~

C

o

N

-•· -· · ,· · , - · •· - -·

•

-· · - · ·

·

·

.,

-., - -- • -- - · · · · · · · · ·

----•

, , - -· · -· ·

-- • ·

·

·

•

-,- -- ,

%

,~

•o ••o ••o •o •o

=~

o

••

o

_0

•

• ·

0

c;I

Z

-·

N

.,

~.

... = ,

U

o

_

•= •o

~

~

o

o

N

N

o

• •o • • •• • •• •• •o

• •

•

•

•

o· • •

• •· •· • ••

N

N

=

o

=

o

o

0

o

o

o

• •

N

N

•

o

o

u ••

Z

~

~

_

c

,

~

•

• •

• •

•o ••

• •

N

zO'

',", -

•

0

:>

c

~

•

•

"

~

"

.... --

~Z­

,¥ lI::"

-"

•

'='•

•

c

·

o

34

o

o

·

o

o

• • ••

o

o

· ·

o

N

N

N

0

o

•

,• • =

,

· · -·

N

-.. . =--

=~~~o

~

g~;;g~

<

~o

_

C

_ ~~~=o~.

=- c - - - ___ '" ....

~.

~c o~~o~

,-, :: c

coeoc~co

o=

occcc

QC -

""C'""C

::O~Q-=:=-::

;;>C'=~I;;=CCC :;;lC:C::OC:

";0:'<:00<':00

__ _

"

%

~~

~,.. ­

~

- ------::':: .

~ \.I

. . '" . . . . . . . . . . . . . .... . .

-,

-._...c: .t: .,.. ...."., ..," . -.,, - .. =_. ._; ,_..." .,'

-- ~"'''' - ''"= - -= - ~- ::-::-~

;. " . "...., ,,;

<:-

-. T

1:='

<

.r

-~

~

~-

.. ., ...;

":'

_

~ ,...

"'

"' .r

<:" ....

"' ..,.

1.~";""=

'- "<

"­

.,;

... ..: - . .... .......

_

, "

'" '"

. _~

~,,~

~-

.

,

,

~

_:0 :;

==-."

•

-

, ;: --- -.-- . . . . .......

. . ""--. .

c.:: __ _ 1 ~ ~; ~;= ~g~~:~~=:~oc=

.

~,,;=--

co=-::==

=-::

__________ ;=:000-::==

--------

=C<':"';C='='C -':

=-

<

•

7 ..

,

:..

.;:

~

< -- I'

--_

.... -' .... I

:::: "'" I

~_

I

; - .' '; ..... - =.'

~

.! .... -: - ':" "" ..,

-:':::10:"" ~ ...

.~ ~:<:

":~-

I

~,.

I

-

"" -----,

-

I

-"

<

--

' j "' _

-'

_

•

I

I

C~'

---.:: -.=. '

"" -::"' ~

•

n

=

,,:_,

N~

=

'!"..,~

~

'~"

,

;;- =,-

'" '!" ;;

~

::.

.~.

~

~ -

<

::

..;

:.;. .:.

.....

·~

NNN ' _ · .N~

'"

..

~==;o=~=o..,oo=o~;

C=~=

.

=

=== ? ==~ ~

.

.• -=-:

-=

= ==== = O= = ~~ ~? ~~~Q~_~ ~=~~ ~ ~ '0' '"

_~

_ __

_-.o.,.-....

?-_u~'~=r'~

,,; ::. .. ... ::1,...

~

=-::.=,, =,,-

-'

.... ...

=: ,.;

./'

~

O ' - ~ -"

.: -::-

._

? ,:",~---- ' ."".

- ... . = .• ___

,- (: -: :: • '" .:". :: -. - .-o.,r.

.... _:- _= ,.

- ::

r

~

•

~~ ..:

,0

CO

./'

,,;

----' . '" :- -

-:

....

~ .- -

........ ." . . . .-.-..

N. . . .

- "" _ =___

----- ... '" ..../' - =

- ~~

...-...

~ ~~.::n=n=

•

.=.--

<

<

......

~ '"

----e> _':.O

l' :- ••

~

~,

;" -'

----------------

...... ..> .:

~.".'

.,.:;~

~:-.-=

...

~=~",

0

,_

, ___

"

"",

, ,

... -. ,_

,

35

__

,

-. • .:!

----= .-

..-

" ..,

.'.., -" ........

-,;-"

--

_

'"

'"~

"'o.....

.~

o

o

II

~

v

e

.~

~"'

C

v:::l

"'

.",

,

o

C

~

,

36

Note: Spoiler has no eff~ct on lift for

lal>17'.

w

"

. I":::::"

-"- -

· (a)

Figure 7

Lift

... Ai r foil Section Characteristics with 20\ Aileron and 10% Spoil e r.

I"': ""1 ":.::: i'LU}.

I: :

•

' Ii::' . . , " i 1,lu~!'! : I :

, '1 •. "

,:;"

I ' ' •. H'i':: , "'. "'1'1 : ·. :' ;:i '.': '.';

" .• " . . "," ." , •. ,.. , .. i. " "·1·" "i ' . ' " " ' . '

,:

:: .:

: .: ,: ,r

~

: : : ~ .:

:

: :: '

•. • I. -: ... _: .;;

.:

: ;.: .: : ' ::.:

::

I".

... .:. I

: : ", fl· . I

: : :

i!i ' :

,..

.•

e""

'··'

.•

"

•.

I""

..

'

"1

I,;:",

"

~

'

i

t'

.,

"

f:::: '. . :;; :::: : :: : : :.": . : .. , '.

:: :: : : : : .

.. ' ''-.

. : ; I ' , . : . , I.· ., "

I,."" " " ,.1'..:;,:1' 'iI'

1..': ': "

, I ~ II ; II H i'

I ,' .. " , . I'

,

i; : I,· ····

II

I

,':

'

•. ' "

171 ';:: , .. " .. , . '

! ": '

. '

1".

:

".. "

; : :.

.

: ::

tlliU ·

,

.;

,......

, ",:cl..:...t,

.,:;;.

: . ......

.

.

.

I·

• •:

::";'

' l:

I

'""""+':c.,, ~*•. '

~i;jlrl

I

..:

.~. " "

,.:

: : :.

., ' :

: '

I: :I i :: :i .' :' .i

,. V . ,t: I

.

, ..

.i": : I"":

: 1111 · ;;" ";:;:

...

: . ;I

'

I

'

i : , . : ': I:

'i

.::

. • ::!

.

:

,;

;',!

:::

i,! i

"" : i"

I I;.

I'.

. ,'

'"

.

!;J;':,'!m;

, ,'

..

:

I: I

.1

1:1

.,

I

, .,

II,

'i::

: .

I I

![ I 'I '" i

I

i II ~rr ~: :

I : ii'

't"I:';'I"

it l'- .: I 1 if'!' •• i i

.

, ' " I'

1'.•.·1:· .'-.·

[;T ' ..•••• ·.· . .

' i'l

:',

. Ii!

. . " . " ,.

. .•.. ,...

. Ii' .

~I.: :":: d,

::: i, ': · " '::~ I

'I'

.

,

;

"

,

"

r:.:, ,' "~ ,; ;'1: l <uU!U,

I'

. ''\: , ' 1 ' ' , :

I •. :.

1: ' "', :. ,.

;

:

'

:

.•

, -I~: !;::

!U··,. ,. ,.'.

, . .,' : " .. i' ' ' : ' 1-'.

'.. W:i y%r-~ , ~ , " I~I~

: •

:

, ~

~I '"

' 1:'

,

i'L

'I

Jbi ' ". l'"-L"

' . '., q.m:~ .

.

i

..•. ..... ·.·.··1: .. I,· ·i · . ;--~ ,.. • .. . .1'\ ., , " ,: i,'

1'" •.• ' '8': ,"1 •. ·. t •... ' I,, ·. ,. .

I '.' i:.'·

r"

. +: ." ,.. ... ',. ··.·{l" I ' . 1- •• ·

.

'

•

.. ,

• ..

.•.

. . , '"

-I

.

.

l _~_;.:'"

= i' •. h· ' '['. I.:{ ......... '·'.. ...•. 'II

..j'.l,e,.

r" ..I . 1' 1 · ' ··. ·1·

. .• ,i."'"

,,.i ,,. , '.'

~

i

.

"

~

.

,

"

•. , ,

I:.•• ·'; '

. 1c .

• ' . ' ,

L. '-'- ."' .

. :11 '1I,!y" ' I : ; , ~ 1-' : ~ ,i . .i· !.' t, I~ jh

1-:..: , . "".,. , ~ ,. :"1"+" I· ... " P '''' 2

•. ,II L>-::'--rv,:.- :,1

. i I'J'

.1

•.... r"..

i l i'; f

I

' Ii'i

' i ,'1 l. 'F'

.. .

fl'!

-: :,/~I I I Y!<I':

:J 1-I''-i. ~ .+ II' " . IU'

LL " .,;

. I ' 1' II'

ro, , ,"

..;". .. . , ",,', .. I' ··· ···..... ... I .!I:; 1'1 . , .• i' I! •. 11, ' LiD

.... ; 1\ L. '~~ !. 1" 1\ .. "1 I " I ,: "1'""

; ! ':i ,. ' i ~!J'

I . i·.I ~ ...'. I ' j,, '. i ."r'~I, ' ; ,.... ' .' '; "~ ' 1

ur,

.' I·· .'·' . . . I"> I " ." , .

,,f,

• . , •. , .

:. ..' . .'. '•. ' :10::::'' ' : .,.- r, ." I: ;;" i " _'i. ' i~ ':0:1" :' ';0; .

'fll.;."I:} •.... ~ .~ .. ' ~ Le· ·I;: ... i ' . !f t~ ' ~ ;1i'

i

,.'..

.:'. · · !. "'.I'· ,H,·· . :" ..,. i ' I " " Ie," ,'.,

•. I '" •. " ':'1 1 '. ,. ..•...• I , .: : ' '1 : 1 .. HlJ;' ,.,.

::.c ~ c...• ' 1".'.J'1' Ii··.·

.Jed' . I . ...... . ' .," ,,"

I ' !.. '.

I'·", . I

.. Ii" I, I; ·t !.:; .2

.' !.._. .,.. .. i. I ' ..i .;

: I: .

: . , r 'l l " •.

'j

o· ·,·e

'1

I I. i

1" , ,"

! '.1 "

38

I'

·It.I ' I'L '.'

-.a

,..

..,•

..,

~

~

.......0

u

~

'"

U

~

....u

~

0

u

r~

~

~

..

....'"

39

A

o

Figure 8 - Effects of Aileron and Spoiler on Power Coefficient.

..

~

Figure

9 - Effects of Aileron Control on Power at 33 RPf1.

c

o

k

•

.....

~

'"

,

, , '- '-, ,

,, , / ,

,,

, , /..... \

-i

-I

'"

'0

I

I

a!,

.c

~

"

0.

C

0

k

....•

.

~

'"

c

o

.~

"•u

.,.'"

"00

'"c

•

k

~

l

0

'0

....•

x

"

k

k

k

~

.~

N

,..,

o

"

N

~

C

0

.~

"

'"•,

U

~

~

a

k

(j

~

42

C

0

....•

.~

"

0

....

•

"'"

'"

k

.~

r--

...

w

ileron

. 69 x / R

1.00 x / R

(b) plan form Schematic

Figure 10 - Concluded

APPENDI X A

Incremental Effects of Control Surfaces

The following equations are based upon experimental data from reference Al .

The airfoil for which these increments were obtained is the NASA

lS (1 )-0421 MOd, a 21 % thick section.

These incremental effects should be

reasonable for the NACA 23024 and other airfoils of similar thickness.

sections less than 15%thick, more appropriate data should be used.

For

The

forms chosen for the incremental equations will have rather general applicability, but the coefficients should be adjusted based on more appropriate

experimental data, when such data are available.

Ailero n Increments

lift :

(A1 )

0° -< 0a -< 60° •

_60 0 -< (; a -< 0° •

•Note:

1·1 , .stall

• sto 11 = 17" for the NACA 23024.

Al

}

(A2 )

Qr!9..:

aC d

=

ca

c (1.05 sin' ' a)

1· 1, .sta ll

0° -< 6 a -< 60° ,

aCd

= ~a

(0 .65 sin' ' a )

_60° -< 6 a -< 0° •

1· 1, ·stall

j

(A 3 )

}

(A 4)

}

(A5 )

}

(A6)

Hinoe Moment:

c

ch

= Ca

( -. 0035 - .0542. - 2.00 sin 6a )

1· 1~ . stall

0° -< 6a _

< 60° ,

ch

ca

=C

( -. 0035 - . 0542. - 2.95 sin 6a )

-60° -< 6 a -< 0° •

1· 1, .stall

Ail eron Effects at Post-Stall Angles

For post-stall cases, no appropriate experi mental data are available.

Therefore theoretical results for Kirchoff flow (fully separated, inv;scid)

will be used.

(S ee reference A2.)

Sketch Al - Kirchoff Flow

A2

The normal force for this flow ;s given by:

(Al)

where

Cn

211'sin a

For a = 90°, equation AB gives cn = O.BB .

ments cn " 2.

(AB)

= 74"""'+=-,"I;'s"';"n7-'-."

From two-dimensional experi-

The discrepancy between theory is primarily because the base

pressure is not modeled properly by the Kirchoff theory . To correct for this

effect. a correction factor K ;s introduced.

tA9)

where

K = 2.0

.88

= 2. 27

This equation (A9) will be used to calculate the normal force for a

deflected aileron at angles of attack beyond stall. where no experimental data

are available . The load distribution will be assumed uniform over the aileron.

The loading on the portion of the airfoil forward of the aileron will be calculated in the usual way. using the data from SUBROUTINE NACAXX.

The steps

in the total calculation process ar e:

1.

Obtain c] and cd as a function of a for the airfoil without

aileron from NACAXX.

2.

Transform lift and drag coefficients to chordwise and normal

force coefficients:

A3

3.

Cc

=

cd * cos(o.)

c t * sin(o.)

(A10)

cn

=

c t * cos (a) + cd * sin(o.)

(A ll )

Calculate the contributions of the area forward of the aileron:

4.

*

(1 - calc)

(A 12)

Cnl = c n * (1 - calc)

(A13)

CCl = Cc

Calculate the aileron normal force coefficient, and resolve

into components parallel and perpendicular to the airfoil chord:

=

2.27*21f*sin(0.+oa)

(A 14 )

4+" Isin(a+oa) 1

normal component:

(A 15)

chordwise component:

(A 16)

5.

Calculate aileron hinge moment:

(A 17)

(Assumes uniform load distribution on aileron. )

A4

6.

Calculate airfoil plus aileron force coefficients:

(A 18)

(A19)

7.

Convert to lift and drag coefficients:

cc * sin(a)

(A20)

cd:: cc*COS (a) + cn*sin(a)

(A21 )

cg, ::

cn* cos(a)

(These are the net sect ion lift and drag coefficients, including

aileron effects.)

8.

Return to mai n program.

Spoil er Increments

Lift:

.c,

= CCs

(-9.9

0° -< 6 s -< 60° ,

1·1, .sta ll

1·1

lIcg, :: 0,

Drag:

,cd

C

= Cs

.

51n os)

(0.93

sin 2 os)

(A22)

(A23)

>a stall

1·1 ~ .stall

0° -< 6 s -< 60° ,

}

}

(A24 )

(A2S)

lIcd :: 0,

1·1> .stall

AS

Hi nge Moment:

ch

=.:.e.

C

(0 .175a - 6.7)(sin 2 ,s)

0° s a S (Is ta 11

ch

=

+

C

ch

(0 .075a - 6.7)(sin 2 , s)

-astall sa

<

0°

lal

>

a stall

= 0,

}

}

References

Al.

Wentz, W.H., Jr., and Fiscko, K.A.: Wind Tunnel Force and Pressure

Tests of a 21 %Thick General Aviation Airfoil with 20%Aileron, 25%

Slotted Flap, and 10% Slot-Lip Spoiler. NASA CR 3081,1979.

A2.

Kennard, E.H.: Irrotational Flow of Frictionless Fluids, Mostly of

Invariable Density. David Taylor Model Basin Report 2299 , 1967.

A6

(A26)

(A27)

(A28)

l\PPENDIX B

Computer Program Listing

TO KUN P~RF ~R ~ANCE STUDIES Dr VARYI NG

WINC SPEED OR RCTATI ONAl SPEE D.

~OCIflEC

PJ{CGR AM "'RCP

L

C

L

C

C

THIS "'RO~~AM WAS CEVEl OPED BY STel N. WAL~ER AND

RUOE RT E. ~ILS ON , DEPAR T~E N T OF ~ECHA~IC~l ~N G [NEERING,

O'EGllN ,!ATE UNIvERSITY. ALL CUEST IONS UP. PROHEMS

CC~CERNING THe "'RUGRAM SHUULD Be DI~EC T EU TO THE ABOVE .

~

C

C

~

C

MOO It-IEU ~y MEL SN YDE R, GILL wENTZ, AND CYRUS OSTOw ARI OF Tt-t WINO

e~ERGY LA B AN U ThE AIRfCIL RESEARCH GROUP AT WICHITA STAT E UNIV ERS

C

C

C

- - - MUUIFICATIGN OA TES -- JUNE TO UC TOBER 19r.

L

L

••••••• MAI~ PRCGRAM ••••••

PROP CALCULATES r~E THE OR ETICAL PERFORMANCE PARAMETERS Of A

'ROPELlER TYPE .I~O TUReINE. IT UTILIze s A SIMPSUN 'S -RUlE

METt-OO I THREE PASS TECt- NIQUE OF 'U"ERICAL I NTEGRAT ION.

C

L

_

(

L

METHOD OF C(NTRCl MAY BE - III PITCHING OF THE TIP SE CTION

121 USE CF DC TeO ARG spellER S

131 USE OF AILE RONS

L

L

C

L

L

L

1

CHOI2,5Cl,ThETX(l,50l,CIMI50J

I HO PEI R,OR,~d,O ,V,X,T H cT P ,A Mao ,H,Sl, GO , O MEG A, RrlO , VIS,H L,

1 PI , RX, 10" ~PRCF , AP f , RAO EG, (aSS I ,( S2, NF ,R R( 50 I , ( I ( 50 I ,r HE TI ( 50 J ,

2 T1 , r 2 , T3, T4 , T5 , Tb , T1 , T8 ,x ETA, HH , MO , CA I I 50 I ,C S I I 50 ) , OA I ( 50) , OS t I 50 I

DIME~S l UN

ca ~~ CN

3,~CGN,HMFtKFLAG

OlloA EN S ION PHD(2) ,PFACT(2)

DATA KW , P~ O,PFACT/lt· ~P ',' KW ',1.3 4 1,1. 1

L

(

•••••••• DEF IN E INPUT AND OUT PUT I'DICES ••••••

L

KH=5

r<.P =6

c

C

IOul=6

•••••••• REAO INPu T CATA •••••••••

REAO (KR,42J~ aOE,N INC,I N (VEl,(NCRPIoA,I PRt~T ,KFLA G

REAO ( KR,10 JR, OR ,H e ,THETP

REAO (~~tl O le,V,C MeG A,AM aO

REAO I KR , .}O )

H,SI,NF,GC,~"ROF

READ I KR ,~ C I

HL,~O ,APFt X ETA.~ H

REAC I KK ,~1)AF1,AF 2 ,Af3,AF4,AF5,~CC N ,TIP I(H ,TI PL , SPAN,O EF L,p (rSPN

RE A0 ( J(.j.{ , 2 a I ( RR , 1 I ,( 1 ( I ) , H i ETI ( 1 I ,( A1 t I J ,( S I

· NFJ

\olRITEIKP,6C)

wRITEtKP.61J

B1

(l

J l OA t ( 1) ,0 S I I I J t I = 1 ,

RM:;:O .JO~d"R

wR 1 TE (KP ,62 J Af 1 ,AFoI! ,AF 3 ,AF~ ,AF5, tl ,R"', 5 J

WRITEtKP,031

GC TO (d4, 9 5, ~o ),~C CN

84 wk l fetKP,(4)l[PICt-',TIPL

GO TO 89

85

~RITE(KP,65)SPA~,P(TSPN,OEFl

WR1TE'KP,67J

GC TO 89

U6 WRITE'KP ,6bISPA~, PC TSP N ,DEFl

WFltTE{KP,681

CC TO (1 ~ ,21,22),KFlAG

19 WRITE(KP,78J

a~

GO TO 91

21 WRITEIKP,79)

GO

TO 91

22 WRITEIKP,83J

9 1 IFIIPRINT.E'.II GC TO 90

WHITE(KP,17J

WRI TE{KP,70J

WRITE(KP,74J

WRITEIKP,15J

WR[TE(KP,76)

wR IT[(KP,7 C I

qa

~G

500 NO:;:l,NINC

IF( IPRINI.E".2I GO TC 13

'rt R ITt:(KP,69)

"' ~ ITC(KP,71J

w.HITEIKP,1Z)

WRITE(KP,731

\,RI TI:(KP,6~)

13

I F(~U~ E.~ C .1) GO

TD 6

IF'~L Oc - Z )4S 9 ,7,4q9

6

~DEL·

INCVEL

1J"'\I +IJOEl

GG TO 8

7 RPl'!iNC=INCRP I'1

a "'I:GA~OM~GA.~PMINC

a

IolI=J.14l5S3

= n11 80 .

FPS~PH :;: 88 ./60.

RAOE~

IST CP =O

SCAlE=l.

CO'TI'UE

R :;: R.SCAlE

HH :;: Hij.SCAlE

OMEGA '

DO

't

l.

l

4

OMEGA/SCALE

I=l,~F

C ""4 ( I I= () .. 304S*SCALE*C 1 t I)

:;: ' " I ) . SC AL E

l io(c:AJ =O

Cl(1)

Ii'i I T I Al \JALUES

51 = R

5 TUR [

S2

S3

=

::I

OR

He

62

Sit '" THETP

S5 = V

S6 = (Me GA

S1 = SI

(

51

IS lONCIN G

A ~G LE

(PSI)

CGSSI=CUSISI*RA OEGI

CSl=CCSSI*CCSSI

W=R~CCSSl*G~E G ~*PI/3u.

x=.,./v If P5P1PH

l.

iNITIALIZATION AND CONSTANT P ARAMETER CALCUlATICNS ••••••

•••••••

C

THETPz-THfTP*R4CEG

V=v*fPSM?H

OMEGA=OMEGA*PI/30.

SI=SI*RAOEG

SUMl = 0.0

SU"2 = 0.0

Q'=C.O

oy=o.o

Tx=O.O

n=o.o

P x= C. 0

PY=O.O

AK= 1.

C

ASTCP=O.O

I~OUCEU vELOCITY FACTORS ARE SET EQUAL TO ZERO TO BEGIN ITERATleN

A=O.O

AP=O.O

HMCPI=C.O

C

CGNTRL=J.C

'(C"TROl' CCUNTS STEP

I~

3-STEP

S[~PSON

Rt;LE tNTEGRAThlN

KHG=Q.OU237t 9 lq~·EXP(-O.2 q 7·H/lOOOO.1

RX=R

C

CORRECT FCR CONING

R=R· COSSI

REF

=BO*k,

l)R=DR*R

ORC=OR

HB=l1u*COSSI

L

L

I ~ "I

IS NUMBE R OF STEPS ACRCSS SPAN,OETERM1"ED fROM INPUT VALUE

CF OR

N~=tR-Ha)/OP+3.

IF! IRE'O.CT.OI

00

11

~O

TO 5

1.::o1,NF

RRtl)=R*K R(IJ/IOU.

U

5

THETI

(l

).aTHET I (J) -tRADEG

C

CCi'lTIf\tJE

SET R LCCAL ECUAl TC RMAX

c

c

•••••••••••••••••••••

NUMERICAL INTEGRATICN FR OM TIP TO HuB ••••••

C

CAT""'l.

IFIGO.EQ.2.1 CAT=2.

83

ClFA-l.

IFI GC .lT.2.1 GO TO 503

lF IGO .E Q. J .1 Cl FA=O. O

IF IIREAG.GT.OI GO TO 211

CA LL SEA RCH IRL,C X1,T HE TXl,CA,C S , DA , OS)

ll!

~

Sb3

C=CAI

TI1 ET = THETXl

CAll CAL CIRl,C,THET, QX ,TX,A,AP,F,ClFA, CAT ,Cl,C Q, ALFA,C H, CA ,( StOA t

20S1

RE -iNITIALIZE 'A'

A=O.O

CAT=O.O

t

~EG I N · M'RCHING

ACROSS

SPA~

FR OM TIP TO HUB

DC l JD l'=l,r-.N

C

50

c

DC r-.cr MARC~ t NSICE HUB

IF IIRl-HBI.GE.ORI GO TO 50

ASTCP: ASr CP+l.

IFIASTOP. GE.2.1 GO TU 9 ~

OR =I Rl-HBI

IF I GO .lT.3.1 GO TC 311

TES T FOR STEP IN 3-POINT SIMPSON

lFIC ON TRl.EQ.O.Ol GO TO 311

TIP=Rl-OR

IFITIP. GT.REFI GO TO 312

IFIC G~TR l.E~.l.1 GO TO 311

DR =(RL- Rcf )

ClFC=IREF-TIPI/IRl-TIPI

C IF''"-. S*CLFC

312

C(' TOl=l.

GC TO III

ClF=O.O

;11

OR2 =00 12.

OT6=vO/ lo.'C OSS II

C

I NCRE ,"1Ef'1IT ' R' IlY

' DR /2'

Rl= Rl- ORl

I F(C CN TRL.EC. O. O) e lF=1.

IF(C ONTRL.EO.2.C) CLF=(ClfO+l.J/2.

I F IIREAD.GT.OI

GO TO 202

L

Fl~O

LWL

CA LL SEAJ<CH (RL,CHO{l,l), rHE TX( 1,l),CA, CS ,OA, IJS I

C=C hJtl, L I

THET -= TrlETX Il,U

C

CA LCULATe

LOCAL CHOReS AND

V~LutS

A~GlES

AT R+OR/2 STATION

CA LL CALC(HL,C,THET,~XPl,IXPl,A,AP,F,ClF,CATrCL,CO,ALFArCH,

ZOA,OS)

INCREMENT R BY OR/2 AGAINITOTAl I'CR<"ENT = OR I

RL=RL-LJR Z

c

ClF·I.

IFICONTOl.EQ.I.OI Clf=ClFO

IFIC ON TRl. E~ . 2 .01 ClF=I. U

IF I(HEALl.CT.OI GO Te 203

FI'O lCCAl CHOReS ANC A'GlES

lu)

CAL L SEAHCH

C=CnO(Z,LJ

IF' CONTR l.E~. C . O l

TNET

~

IRL,ChOll.,l),THETX(Z,LJ,CA,CS. DA,DS )

THETXIZ,LJ

64

CA,CS,

C

CALCULATE VALUES AT R.OR STATION

CALL

CALCIRl,CfrH(T,QXp,rX~,A,AP,F,CL~,C~T,CL,CO,AlFA,Ch,CA , es .DA,

2051

THETA=LUCAL ELACE T'IST'PITCH SE TTIN G

THETA=THET+T~ETP

c

PCRL=(lOO.I·RL/R