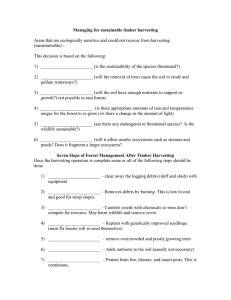

I E V F

advertisement